Description

Introduction of Dynamic Batching Machine

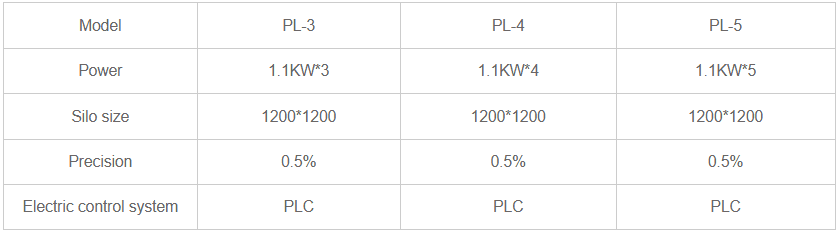

The dynamic batching machine is suitable for the site of continuous batching, such as fertilizer batching. These sites have higher requirements on the continuity of the batching, which generally do not allow the intermediate batching to stop, and the requirements for the proportioning of various materials are strict. The dynamic batching system is usually measured by electronic belt scale or nuclear scale, and the host has PID regulation and alarm function, which can realize the automatic control of a warehouse.

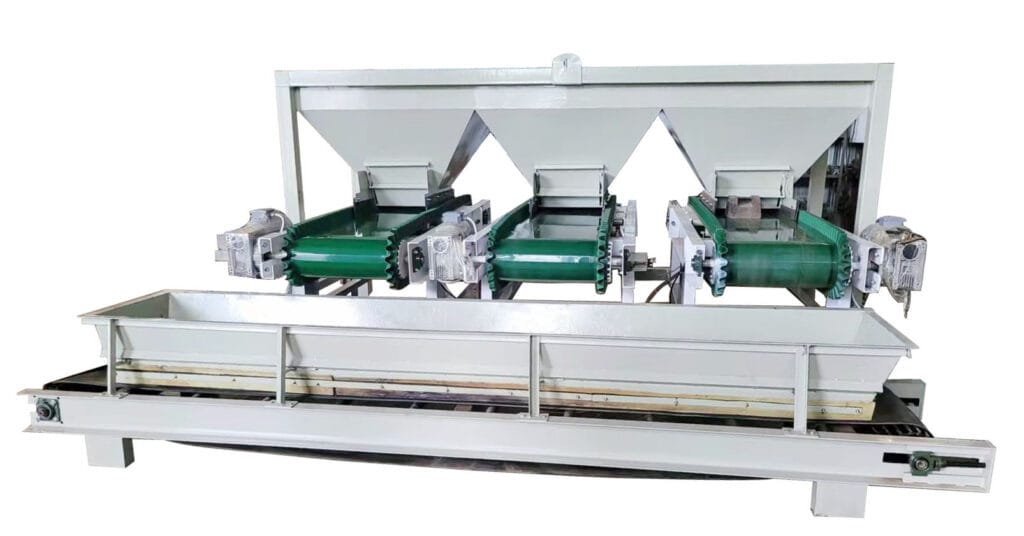

Structure of Dynamic Batching Machine

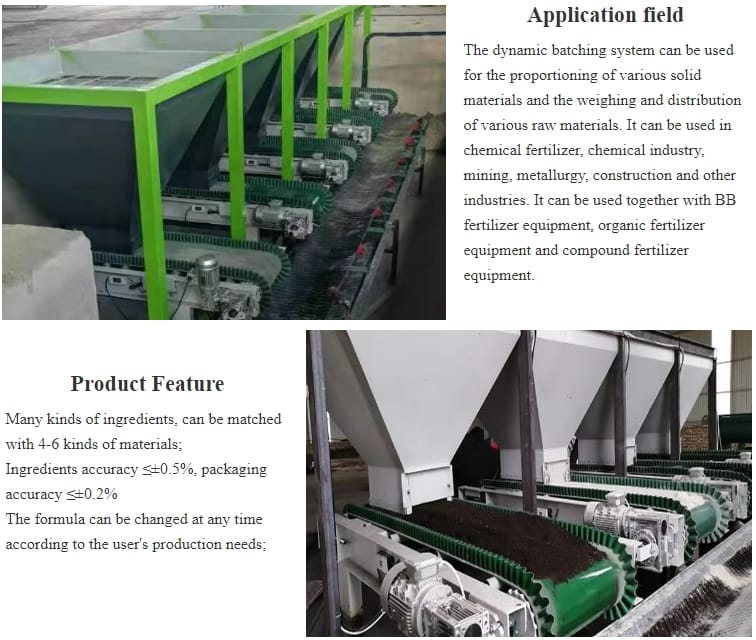

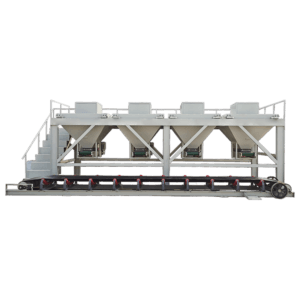

Application of Dynamic Batching Machine

In a complete fertilizer production line, it is to be designed and used to batch the raw materials for three to eight. And mostly it is to be equipped in the organic fertilizer production line or NPK compound fertilizer production line and other series fertilizer production line. Generally, the machine is to be used to finish the batching system is more accuracy of the ration of the raw materials.

Product Feature of Dynamic Batching Machine

Electronic belt scale, by the scale frame, speed sensor, weight sensor, electronic belt scale control display instrument, etc., can carry out continuous dynamic measurement of solid materials.

Electronic belt scale weighing bridge is installed on the conveyor frame, when the material passes through, the metering roller detects the weight of the material on the belt through the lever on the weighing sensor, generating a voltage signal proportional to the belt load. The speed sensor is directly connected to the large diameter speed measuring drum, providing a series of pulses, each pulse represents a belt movement unit, pulse frequency proportional to the belt speed. The weighing instrument receives the signal from the weighing sensor and the speed sensor, and obtains an instantaneous flow value and accumulated weight value through integral calculation, and displays them respectively.

Reviews

There are no reviews yet.