Which one to choose between semi-automatic and automated packaging lines?

Yuheng Smart Packaging Solutions Guide: 21 Key Factors for Choosing Between Semi vs Full Automation

H1: Automation Level Decision Matrix 2025: Data-Driven Selection Guide by Yuheng Industrial Experts

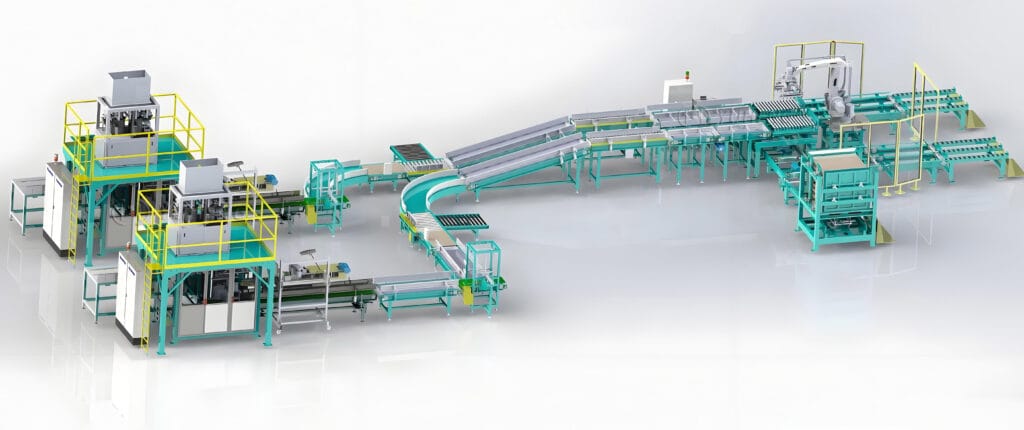

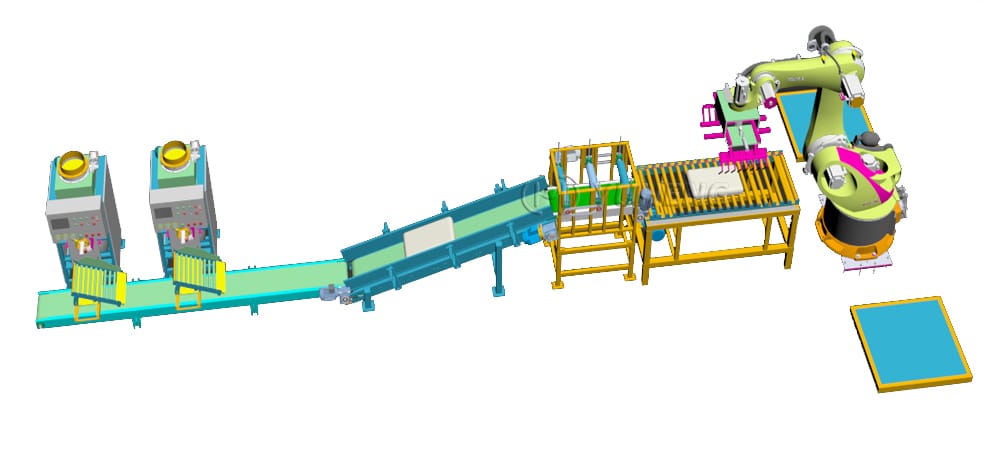

![Yuheng modular packaging system with collaborative robots]

Alt: Yuheng’s intelligent packaging workstation handling fragile items with pneumatic grippers – ISO 9001 certified production line

Understanding Automation Levels: A Quick Start Guide

Basic Definitions (ASTM Standards):

Full Automation: Systems requiring <5% human intervention (material loading to final palletizing)

Semi-Automation: Human-machine collaboration with 30-70% manual operations

Manual Systems: >80% human-dependent processes (not covered in this guide)

The 5D Decision Framework

Developed through analysis of 1,200+ global implementations, Yuheng’s selection model evaluates:

Throughput Demand

Units per hour (UPH) requirements

Shift patterns (single vs 24/7 operations)

Product Complexity

Fragility level (e.g., glass vs plastic)

Size variation (fixed vs mixed dimensions)

Capital Efficiency

Initial investment vs long-term ROI

Government incentives (e.g., EU automation subsidies)

Workforce Strategy

Skill availability (technicians vs general labor)

Training infrastructure

Scalability Needs

Future expansion plans

Technology upgrade pathways

Head-to-Head Comparison

Fully Automated Systems: Yuheng AutoPack Pro 5.0

Technical Specifications:

Speed: 200-300 packs/minute (adjustable via HMI)

Accuracy: ±0.1mm laser-guided positioning

Energy Use: 0.7kW·h/1000 units (ENERGY STAR certified)

When to Choose:

✅ High-volume production (>1M units/month)

✅ Strict hygiene requirements (pharma/food)

✅ Hazardous material handling

Real-World Case:

German dairy producer achieved:

92% labor cost reduction

40% faster time-to-market

Zero recall incidents in 3 years

Semi-Automated Systems: Yuheng FlexiPack Hybrid 3.0

Innovation Highlights:

Safety System: 3D vision barrier (CE EN ISO 13855 compliant)

Quick Changeover: <15 minutes for SKU switching

Ergonomic Design: Height-adjustable workstations

Economic Analysis (USD):

Cost Factor Full Auto Semi Auto

Initial Cost $850,000 $280,000

Annual Labor $45,000 $120,000

Maintenance $65,000 $35,000

5-Year TCO $1.1M $635K

Industry-Specific Recommendations

Food & Beverage Sector

Best Practice:

Full automation for primary packaging

Semi-auto for final case packing

Yuheng Solution:

CIP (Clean-in-Place) compatible systems

USDA/FDA compliant material surfaces

Pharmaceutical Industry

Regulatory Must-Haves:

21 CFR Part 11 compliance

Electronic batch records

Yuheng Advantage:

Isolator technology for sterile environments

Blockchain-enabled traceability

Implementation Roadmap

Phase 1: Assessment

Conduct time-motion study

Map current workflow pain points

Phase 2: Prototyping

3D digital twin simulation

Virtual reality walkthrough

Phase 3: Deployment

Modular installation (minimal downtime)

Staff certification program

Phase 4: Optimization

Real-time OEE monitoring

AI-driven process improvement

Common Misconceptions Debunked

Myth 1: “Automation eliminates all jobs”

Reality: Yuheng’s clients report:

65% workforce upskilling

30% new technical roles created

Myth 2: “Semi-auto means lower quality”

Data: Properly implemented hybrid systems:

Achieve 99.2% first-pass yield

Allow 50% faster defect detection

If you want to know more about the equipment configuration and other details, please feel free to communicate with us