What’s the Price of Millet Packaging Machines? Essential Maintenance Precautions

Millet packaging machines are critical for agricultural processors and health food manufacturers globally. As a trusted Chinese innovator, Yuheng Technology Co., Ltd. delivers precision systems that balance affordability with hygienic design, exemplifying China’s expertise in grain-specific packaging solutions.

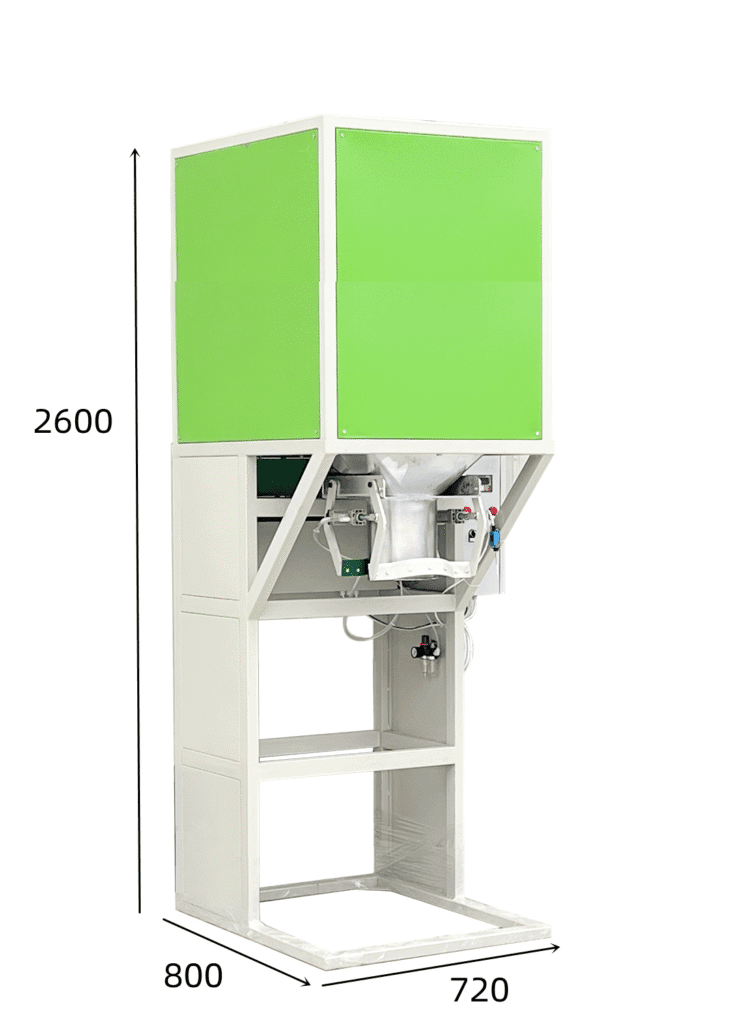

Millet Packaging Machine Pricing Overview

Complete systems range from $2,000 to $85,000+, influenced by:

- Capacity: 1,000–5,000 bags/hour configurations

- Automation Level: Semi-automatic vs. robotic palletizing

- Sanitary Standards: Food-grade stainless steel construction

- Smart Features: AI-powered grain flow optimization

Chinese-engineered machines like Yuheng’s models offer 30–45% cost advantages over European counterparts while meeting ISO 22000 and HACCP certifications – ideal for global buyers prioritizing food safety and value.

6 Critical Maintenance Protocols for Millet Packers

1. Comprehensive Safety Lockdown

- Execute 3-step power isolation:

- Disconnect main circuit breaker

- Depressurize pneumatic systems (0.5MPa residual release)

- Engage mechanical safety locks

- Yuheng Safety Feature: Dual-circuit emergency brakes prevent accidental startups

2. Operational Familiarization

- Study machine blueprints highlighting:

- Gravity feed pathways (50–70° optimal angles)

- Sensor locations (20+ critical monitoring points)

- Quick-access maintenance panels

- Yuheng Advantage: Augmented reality manuals visualize internal components

3. Specialized Tool Preparation

- Essential toolkit includes:

- Non-magnetic tools (prevents grain contamination)

- 0–25Nm torque wrench for precision adjustments

- Laser alignment devices for conveyor systems

- Pro Tip: Color-code tools for specific maintenance zones

4. Hygienic Cleaning & Lubrication

- Daily:

- Vacuum residual grains from weighing sensors

- Wipe food-contact surfaces with food-safe ethanol

- Weekly:

- Lubricate chain drives with NSF H1-certified grease

- Clean air filters with reverse-pressure airflow

- Yuheng Innovation: Self-lubricating bushings extend service intervals

5. Precision Drive System Inspection

- Check critical components:

- V-belt tension (5–8mm deflection at 10kg force)

- Gearbox backlash (<0.1mm tolerance)

- Sprocket tooth wear (>1mm = replacement)

- Maintenance Alert: Yuheng’s vibration analysis kits detect early wear patterns

6. Electrical System Verification

- Essential checks:

- Motor insulation resistance (>100MΩ at 500VDC)

- Photoelectric sensor alignment (±1mm accuracy)

- Terminal block torque values (0.5–2.0Nm specs)

- Yuheng Smart Feature: Wireless thermal scanners identify hot spots in live circuits

Yuheng Technology’s Maintenance Innovations

- Modular Design: Replace auger screws in 10 minutes without full disassembly

- Dust-Tight Electronics: IP69K-rated control panels withstand high-pressure washdowns

- Predictive Maintenance: IoT sensors forecast component failures 200 operating hours in advance

- Global Compliance: Meets USDA and EU 1935/2004 food contact regulations

Why Choose Chinese Millet Packers?

- Specialized Engineering: 12 years refining systems for small grains (0.8–2.5mm)

- Cost Efficiency: 40% lower spare parts costs than Japanese equivalents

- Adaptive Scaling: Upgrade from 500 to 5,000 bags/hour capacity

- Sustainability Focus: Energy recovery systems reduce power use by 25%

Yuheng Technology Co., Ltd. embodies China’s manufacturing excellence – delivering millet packaging solutions that combine precision with operational reliability. With 120+ installations across 18 countries, our machines help processors maintain strict hygiene standards while maximizing throughput.