What’s the Price of Granule Packaging Machines? Common Causes of Uneven Sealing or Seal Failure

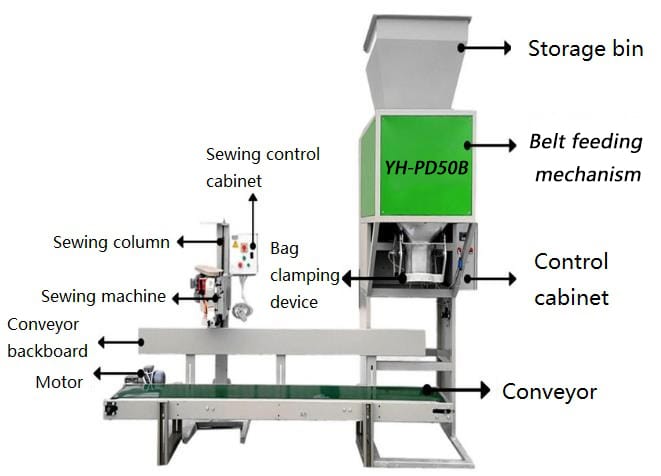

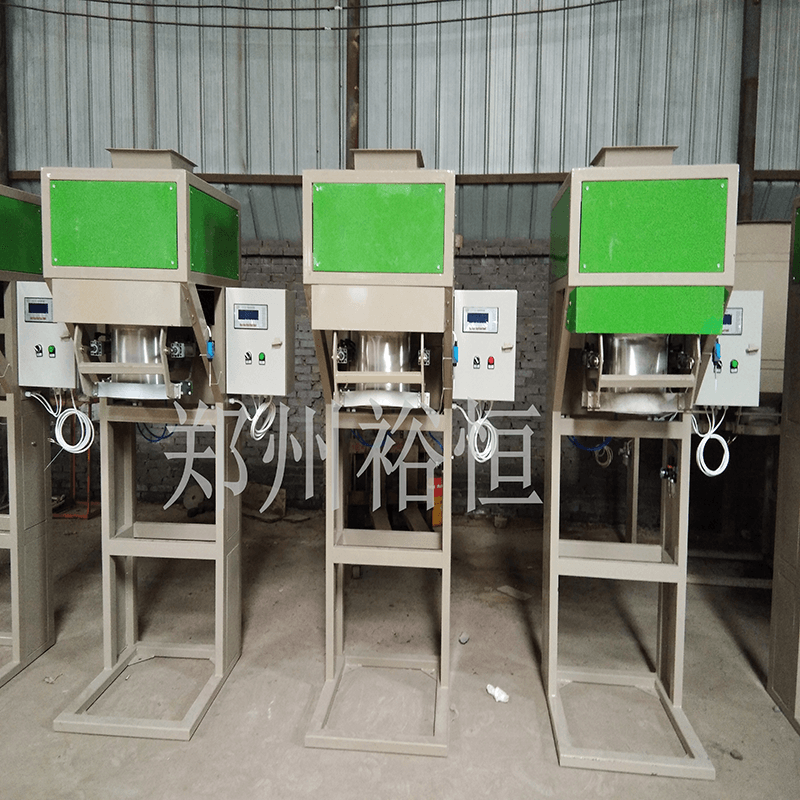

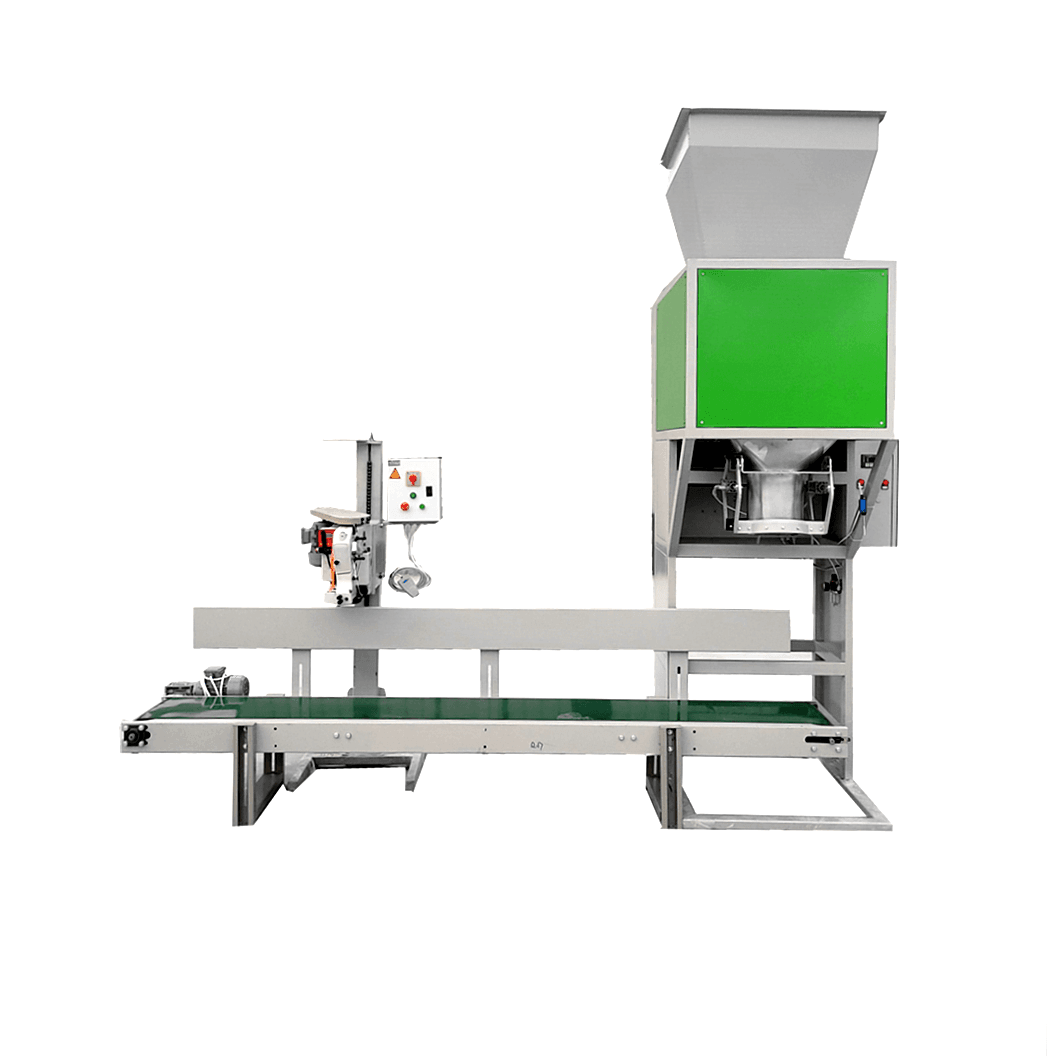

When investing in granule packaging machines, understanding equipment pricing factors and operational challenges helps international buyers make informed decisions. As a trusted Chinese manufacturer, Yuheng Technology Co., Ltd. combines cost-effective production with reliable technical solutions for global clients.

Granule Packaging Machine Price Range

Packaging equipment costs vary significantly ($3,000-$50,000+) depending on:

- Production capacity (bags/hour)

- Automation level (semi-auto vs full-auto)

- Material compatibility (film types)

- Additional features (multi-head weighers, dosing systems)

Chinese-manufactured machines like ours typically offer 25-40% cost advantages compared to European counterparts while maintaining ISO-certified quality standards.

6 Key Causes of Uneven Sealing/Seal Failure

- Temperature Imbalance

Incorrect heat settings remain the most frequent sealing issue. Our packaging machines feature dual-zone temperature controls that maintain consistent 150-200°C ranges, adapting to different film materials while preventing overheating damage common in basic models. - Insufficient Sealing Duration

Short contact time creates weak seals. Yuheng’s systems incorporate adjustable timing mechanisms (0.5-5 seconds) with visual operation guides, allowing quick adaptation to various packaging speeds and material thicknesses without technical expertise. - Damaged Sealing Components

Worn heat bars compromise performance. We use Japanese-grade nichrome alloy heating elements in our packaging machines, lasting 2-3 times longer than standard parts. Our global clients receive replacement alerts through smart monitoring systems. - Inadequate Pressure Application

Low compression force causes incomplete bonding. Our servo-driven sealing mechanisms maintain 20-30N/cm² pressure consistently, with self-adjusting functions that compensate for mechanical wear – a patented feature in Yuheng’s mid-range models. - Material Compatibility Issues

Substandard films lead to sealing failures. Our technical team provides free material testing services, recommending suitable Chinese-made laminated films that ensure 98%+ seal success rates while reducing material costs by 15-20%. - Mechanical Misalignment

Loose components disrupt operations. All Yuheng granule packaging machines undergo 72-hour continuous test runs before shipment, with laser-aligned sealing modules that maintain precision through 10,000+ operating hours.

Sustainable Solutions from China’s Expertise

Yuheng Technology Co., Ltd. addresses these challenges through:

- Modular designs enabling easy part replacements

- Multilingual touchscreen interfaces for error diagnosis

- Remote maintenance support via IoT connectivity

- Energy-efficient systems reducing power consumption by 30%

Our packaging machines exemplify China’s manufacturing evolution – blending affordability with smart functionality. With 18 years of export experience, we help global clients optimize their packaging operations while minimizing lifecycle costs.