What Is the Price of Granule Packaging Machinery? A Step-by-Step Breakdown of Its Packaging Process

Granule packaging machinery has revolutionized production lines across industries, combining precision engineering with cost-effective automation. As an industry leader, YU-HENG Technology leverages China’s advanced manufacturing capabilities to deliver robust systems that outperform competitors in both affordability and technical sophistication.

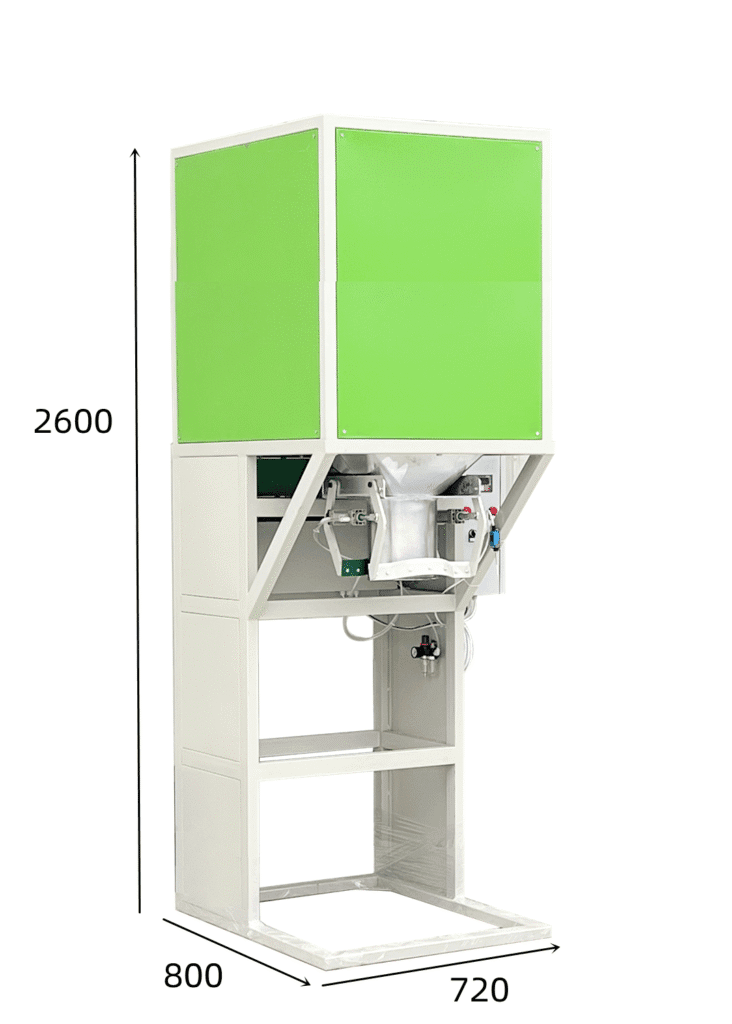

Granule Packaging Machinery Pricing Overview

YU-HENG Technology offers tiered solutions to match diverse operational needs:

- Basic semi-automatic units: $25,000–$40,000

- Mid-range automated systems: $45,000–$120,000

- Customized high-speed lines: $180,000+

Chinese-manufactured equipment typically delivers 25–35% cost savings compared to European equivalents while maintaining ISO 9001-certified quality standards.

Granule Packaging Process: 6 Key Stages

1. Material Preparation & System Setup

YU-HENG systems accommodate a wide range of granules:

- Particle size: 0.04″–0.4″ (1–10 mm)

- Flow characteristics: From free-flowing seeds to cohesive powders

- Packaging materials: Compatible with laminated films, kraft paper, and biodegradable polymers

Our SmartLoad™ calibration ensures optimal material handling within 15 minutes of setup.

2. Precision Feeding & Dosing

Advanced metering technologies ensure accuracy:

- Loss-in-weight feeders: ±0.35 oz (10 g) consistency

- Vibratory channels: Adjustable amplitude for fragile granules

- Multi-head weighers: 8–16 weigh buckets for high-speed operations

YU-HENG’s patented Anti-Bridging Design eliminates material clogs, achieving 99.2% uptime.

3. Bag Formation & Structuring

Our machinery creates customized packaging:

- Bag styles: Pillow, gusseted, or block-bottom

- Size range: 4″×6″ to 20″×30″ (10×15 cm to 50×76 cm)

- Seam integrity: Laser-scored tear notches and reinforced side seals

Integrated vision systems verify template alignment within ±0.02″ (0.5 mm).

4. Automated Filling & Product Handling

YU-HENG’s filling solutions feature:

- Dual-stage vibration: Ensures complete bag filling without particle damage

- Nitrogen flushing: Oxygen levels <0.8% for sensitive products

- Multi-lane distribution: Simultaneous filling of 2–4 bag lines

Production speeds range from 60–120 bags/minute depending on granule characteristics.

5. Sealing & Quality Assurance

Advanced closure methods guarantee protection:

- Heat sealing: Adjustable 300–450°F (149–232°C) jaw temperatures

- Cold seal activation: Pressure-sensitive adhesives for heat-sensitive products

- Leak detection: Air-pressure testing at 0.5–1.5 PSI (3.4–10.3 kPa)

YU-HENG’s TripleCheck™ system combines thermal imaging, weight verification, and barcode scanning.

6. Final Cutting & Packaging

Post-sealing processes ensure market readiness:

- Servo-driven cutting: Clean separation without material fraying

- Automatic stacking: Palletizing up to 50 lb (22.7 kg) bundles

- Batch coding: Laser-marked production dates/lot numbers

YU-HENG Technology’s Competitive Advantages

- Smart Automation: IoT-enabled predictive maintenance reduces service costs by 40%

- Energy Efficiency: Regenerative drives cut power consumption by 18–22%

- Global Compliance: Meets FDA, EU 10/2011, and GB 4806 standards

- Custom Engineering: Modular designs allow future upgrades without line replacement