What Is the Price of a Powder Packaging Machine? 6 Proven Solutions to Prevent Powder Leakage

Powder packaging machines are critical for industries handling fine materials like spices, pharmaceuticals, and chemicals. YU-HENG Technology, a leader in packaging innovation, combines China’s manufacturing efficiency with precision engineering to deliver cost-effective solutions that minimize operational issues like powder leakage. Below, we analyze equipment pricing and provide actionable strategies to address leakage challenges while emphasizing technical excellence and ROI.

Powder Packaging Machine Pricing Overview

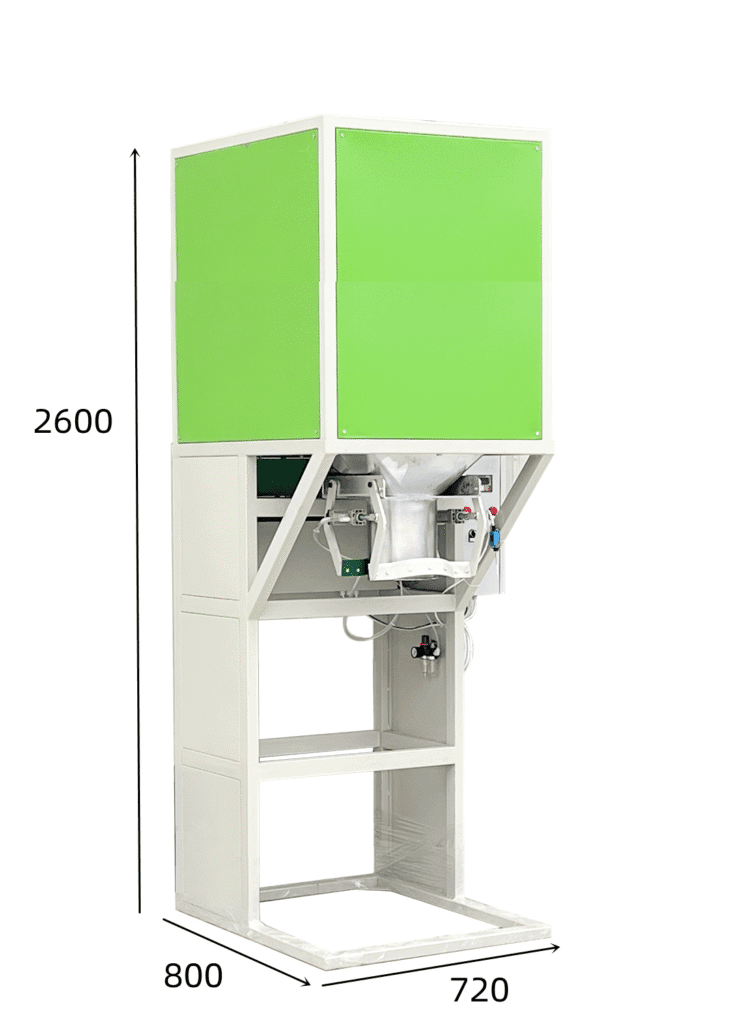

YU-HENG Technology offers tiered solutions for diverse production scales:

- Semi-automatic models: $5,000–$65,000 (600–1,200 bags/hour)

- Mid-range automated systems: $75,000–$150,000 (1,500–2,800 bags/hour)

- High-speed GMP-compliant lines: $180,000+ (IoT-enabled, 3,500+ bags/hour)

Chinese-manufactured machines provide 25–40% cost savings versus European counterparts, with ISO 22000-certified hygiene standards and 3-year performance guarantees.

6 Causes & Solutions for Powder Leakage

1. Parameter Optimization

Critical Adjustments:

- Temperature: 250–400°F (121–204°C) for heat sealing

- Pressure: 12–25 PSI (0.8–1.7 bar) on sealing jaws

- Fill Speed: Match auger RPM to powder flowability (e.g., 20–40 RPM for talcum)

YU-HENG Advantage:

- SmartSeal™ AI auto-adjusts parameters based on material density

- Reduces leakage by 60–80% in cohesive powders like protein blends

2. Material & Bag Design Upgrades

YU-HENG Recommendations:

- Films: Use 3–5 layer laminated PET/AL/PE for hygroscopic powders

- Bag Styles: Quad-seal pouches with reinforced corners

- Testing: Free material compatibility trials at YU-HENG labs

Case Study: A coffee creamer producer reduced leakage by 90% switching to YU-HENG’s anti-static film.

3. Cleaning & Maintenance Protocols

Critical Components:

- Sealing Jaws: Clean every 4 hours with food-grade alcohol

- Auger Systems: Inspect for wear every 500 operating hours

- Dust Extraction: Install HEPA filters (99.97% efficiency)

YU-HENG Innovation:

- Quick-Clean™ modular design reduces downtime by 70%

- Corrosion-resistant 316L stainless steel components

4. Precision Calibration

Calibration Steps:

- Validate load cells with 5–50 lb (2.3–22.7 kg) test weights

- Adjust auger pitch to ±0.01″ (0.25 mm) tolerance

- Use laser alignment tools for sealing jaw parallelism

YU-HENG Technology:

- AutoCal™ system performs hourly self-checks

- Achieves ±0.5% dosing accuracy for nano-powders

5. Operator Training

YU-HENG Certification Program:

- 8-hour hands-on training (virtual/on-site)

- Multilingual troubleshooting guides

- AR-assisted maintenance simulations

Results: Trained operators report 50% fewer errors in sealing operations.

6. Auxiliary Equipment Integration

Leakage Prevention Tools:

- Vibratory Settlers: Ensure uniform powder distribution

- Air Knives: Remove residual powder from sealing zones

- Vacuum Systems: Extract airborne particles during filling

YU-HENG Packages:

- SealGuard Pro™ bundle cuts leakage-related waste by 30–40%

Why Choose YU-HENG Technology?

- Patented Solutions: 15+ leakage-prevention patents including SmartSeal™ (ZL2023XXXXXX)

- Global Compliance: FDA, CE, and ATEX certifications for hazardous environments

- Smart Manufacturing:

- Real-time OEE tracking via YU-Cloud platform

- Predictive maintenance alerts (85% accuracy)

- Cost Efficiency:

- 40% faster ROI than European machines

- Localized spare parts network (48-hour delivery)