What Is the Price of a Fertilizer Packaging Machine? Key Precautions for Safe Operation

Fertilizer packaging machines are essential for streamlining agricultural production, balancing efficiency with safety. At Yuhang Technology Co., Ltd., we combine China’s manufacturing expertise with globally compliant designs to deliver reliable fertilizer packaging machines. This article breaks down pricing factors and outlines critical precautions to ensure safe and productive operations.

Fertilizer Packaging Machine Price Range

The cost of a fertilizer packaging machine depends on its automation level, capacity, and material compatibility. Basic semi-automatic models start at $12,000 to $25,000, while fully automated systems with advanced weighing and sealing features range from $30,000 to $80,000+. As a competitive Chinese manufacturer, Yuhang Technology offers durable, cost-efficient solutions that align with the precision and affordability of “Made in China.”

Key Precautions for Operating Fertilizer Packaging Machines

To maximize safety and equipment longevity, adhere to these guidelines when using packaging machinery:

1. Follow Operational Protocols

Always review the user manual provided by Yuhang Technology before operation. Train staff on startup/shutdown procedures, emergency stops, and troubleshooting to avoid mechanical failures.

2. Wear Protective Gear

Equip operators with safety goggles, gloves, dust masks, and noise-canceling earplugs. Fertilizer dust and machine noise pose health risks during prolonged use.

3. Pre-Operation Inspections

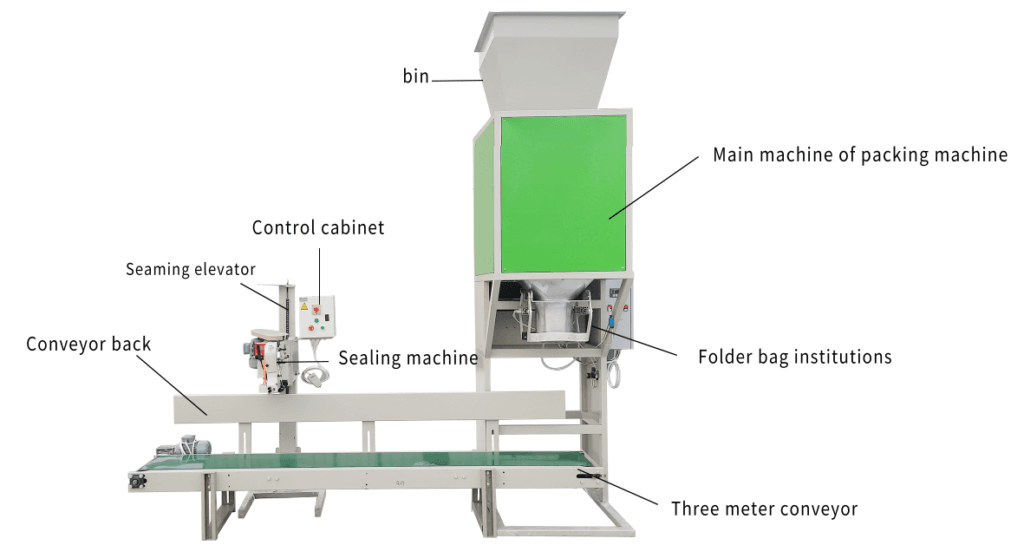

Check critical components like conveyor belts, sensors, and sealing jaws daily. Ensure bolts are tightened and no debris obstructs moving parts.

4. Optimize Control Panel Settings

Calibrate settings for bag size, weight accuracy, and speed based on fertilizer type (e.g., granular vs. powdered). Test settings with a small batch before full-scale production.

5. Avoid Sudden Interventions

Never force open covers or adjust parts mid-operation. Sudden stops or manual interventions can damage motors or cause material spillage.

6. Implement Cleaning Routines

After each shift, remove fertilizer residues from hoppers, nozzles, and workstations. Use compressed air or non-abrasive tools to prevent corrosion and blockages.

7. Schedule Professional Maintenance

Partner with Yuhang Technology’s service team for quarterly inspections of electrical systems, lubrication points, and wear-prone parts like blades and belts.

8. Monitor Environmental Safety

Store machines in well-ventilated areas to minimize dust accumulation. Install fire extinguishers nearby, as fertilizer dust is highly combustible.

Why Yuhang Technology Stands Out

Yuhang Technology Co., Ltd. designs fertilizer packaging machines that prioritize safety, durability, and ease of maintenance. Our machines comply with international agricultural standards, showcasing China’s ability to produce high-tech, user-friendly industrial equipment. With 24/7 global support, we ensure your operations stay efficient and incident-free.

Contact us today to explore tailored packaging solutions that protect both your workforce and productivity!