What Determines Coal Packaging Machine Prices? Challenges Amid Rapid Industry Growth

The coal packaging machinery sector has experienced significant growth in recent years, driven by rising global energy demands and industrialization. However, as the industry evolves, it faces several challenges that businesses must address to ensure sustainable progress. Yuhang Technology Co., Ltd., a Chinese leader in innovative packaging solutions, combines cost-effective engineering with adaptive designs to tackle these issues head-on. Below, we explore key challenges in coal packaging machinery development and how strategic partnerships with manufacturers like Yuhang Tech can mitigate risks.

1. Balancing Upfront Costs with Long-Term Value

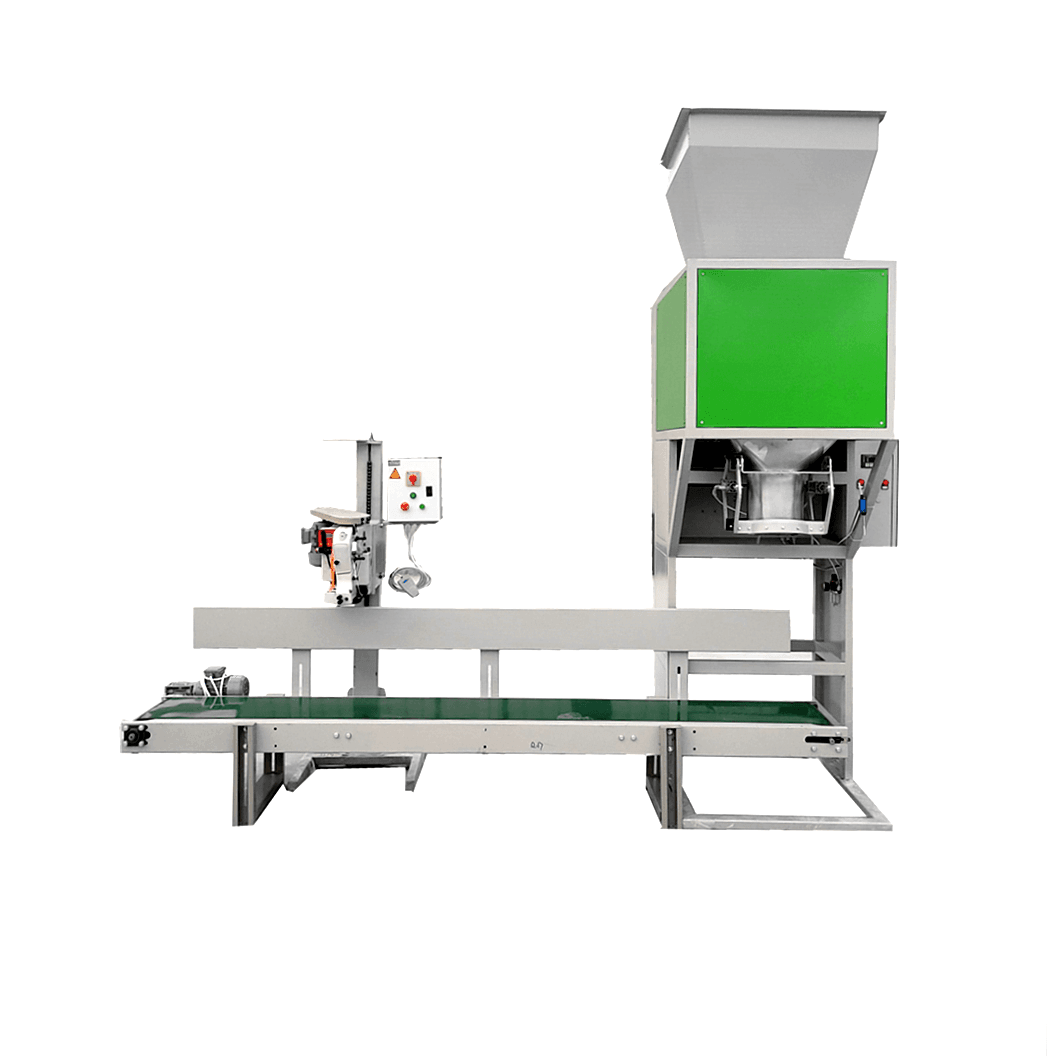

While advanced coal packaging machines improve efficiency, their initial price remains a hurdle for small and mid-sized enterprises. High-quality automation systems and precision components often push prices into the $50,000–$200,000 range, straining limited budgets. However, Chinese manufacturers like Yuhang Tech have addressed this by optimizing production processes and leveraging localized supply chains, reducing costs without sacrificing durability. For example, our modular packaging systems allow clients to start with basic configurations and upgrade later—a flexible approach that eases financial pressure.

2. Adapting to Diverse Packaging Requirements

Modern coal producers face varying packaging demands, from moisture-resistant bags for export to compact formats for retail distribution. Standardized machines often struggle with such diversity, requiring frequent adjustments or custom parts. Yuhang Tech tackles this challenge by integrating adjustable sealing mechanisms and programmable control panels into our equipment. A recent collaboration with an Indonesian mining firm saw us redesign hopper capacities and conveyor speeds to handle three coal grades simultaneously, proving adaptability is achievable without exorbitant R&D costs.

3. Overcoming Technical Complexities in Design

Advanced features like automated weighing or dust suppression systems introduce technical complexities. Smaller manufacturers may lack the expertise to troubleshoot sensor errors or software glitches, leading to prolonged downtime. Yuhang Tech’s R&D team prioritizes user-friendly interfaces and failsafe mechanisms. By adopting simplified maintenance protocols and AI-driven diagnostics in our latest models, we’ve reduced average repair times by 35% for clients in South Africa and India.

4. Minimizing Maintenance Costs and Operational Disruptions

Complex machinery inevitably requires upkeep, but unplanned breakdowns can cripple production schedules. High-precision components like hydraulic sealers or laser-guided cutters demand specialized technicians, which are scarce in remote mining regions. To counter this, Yuhang Tech established a global service network offering remote troubleshooting and priority spare parts delivery. A Canadian client reported a 50% reduction in maintenance-related downtime after switching to our machines, supported by predictive maintenance alerts via IoT-enabled sensors.

5. Meeting Environmental Compliance Standards

Environmental concerns—noise pollution, wastewater from cooling systems, and carbon emissions—are growing scrutiny areas. Regions like the EU now enforce strict noise limits (below 75 dB) and wastewater recycling mandates for industrial equipment. Yuhang Tech’s eco-focused designs, such as energy-recovery motors and closed-loop water filtration, help clients meet these standards. Our partnership with a Mongolian coal producer reduced their annual wastewater discharge by 60%, aligning operations with local sustainability laws.

Yuhang Tech: Pioneering Practical Solutions for Global Clients

As a Chinese manufacturer with a decade of industry experience, Yuhang Technology Co., Ltd. understands the unique pressures facing coal producers today. By blending China’s manufacturing scalability with client-centric innovation, we deliver packaging machines that balance affordability, adaptability, and compliance. Our ISO-certified factories employ lean production techniques to keep prices competitive, while regional customization teams ensure equipment aligns with local operational needs.

Addressing the challenges of coal packaging machinery requires more than technical expertise—it demands collaboration. Yuhang Tech works closely with clients to develop phased upgrade plans, financing options, and eco-compliance roadmaps. Whether you operate a small-scale mine or a multinational energy conglomerate, our solutions prioritize your operational continuity and environmental responsibilities.

Contact Yuhang Technology Co., Ltd. today to discover how Chinese engineering excellence can transform your coal packaging process while keeping costs predictable and sustainable.