Vertical vs. Horizontal Packaging Machines: Price Comparison and Key Differences

When choosing packaging equipment for your production line, two critical questions often arise: What is the investment range for vertical packaging machines? and What fundamentally distinguishes them from horizontal (pillow-type) packaging machines? As a leading Chinese manufacturer with 15+ years of global export experience, Yuheng Technology Co., Ltd provides this practical comparison to help international buyers navigate their packaging equipment selection process.

The price spectrum for vertical packaging machines typically spans from $20,000 to $150,000+, with variations depending on automation level and special features. Entry-level vertical packaging machines from Yuheng Technology start around $20,000-$50,000, offering reliable semi-automatic operation ideal for small to medium businesses handling free-flowing products like coffee, spices, or detergent powders. More sophisticated models priced between $55,000-$100,000 incorporate servo-driven mechanisms and user-friendly touchscreen controls, while premium systems exceeding $110,000 deliver full automation with smart sensor technology for large-scale production environments.

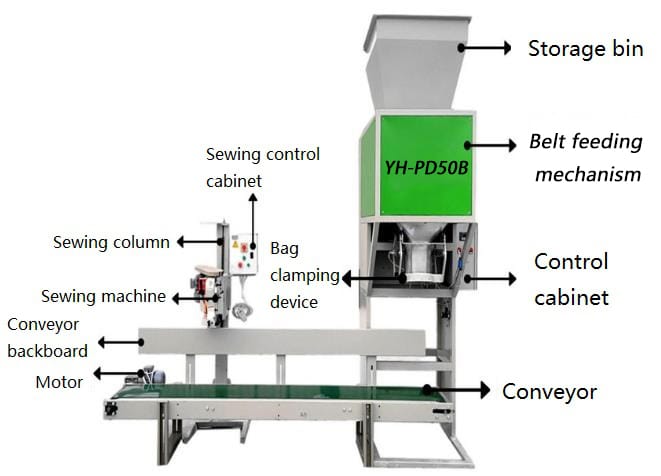

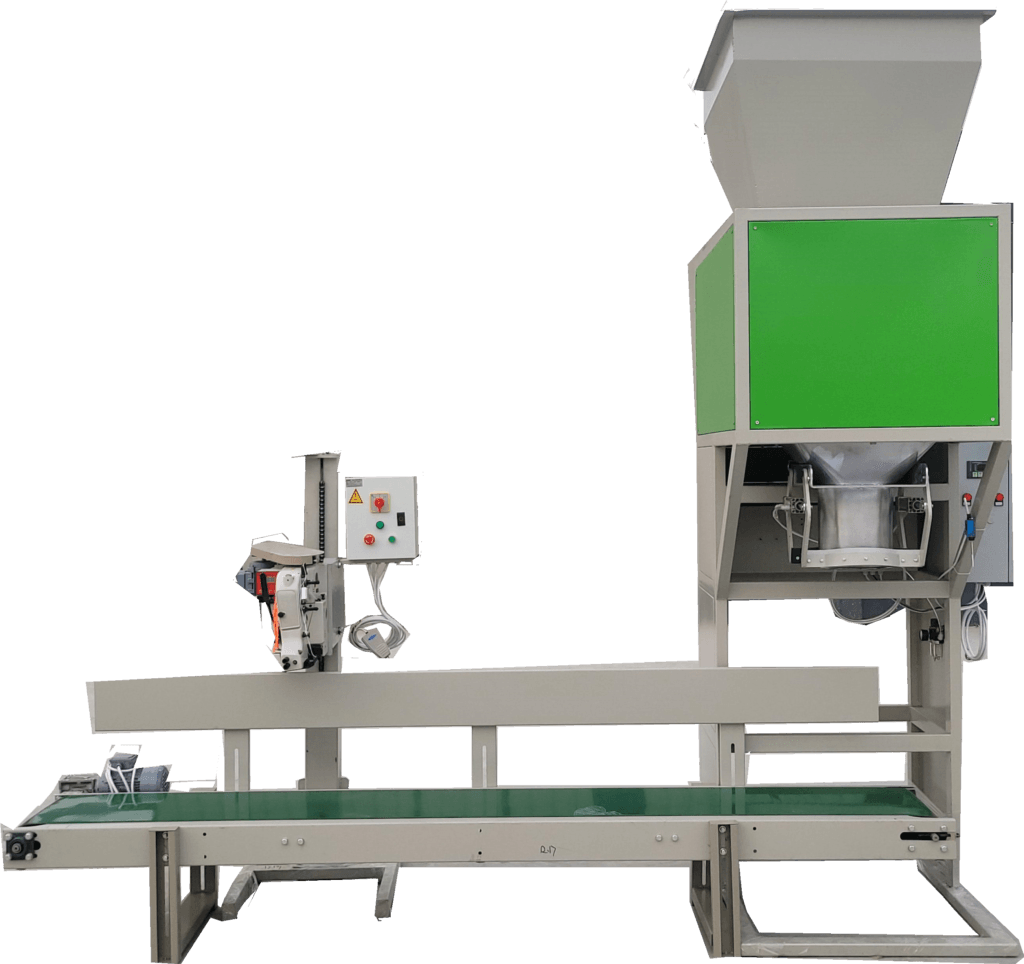

Understanding the operational differences between vertical and horizontal packaging machines is crucial for making the right investment. Vertical packaging machines, as the name suggests, operate in an up-down orientation with film unwinding from a top-mounted roll. This design makes them particularly suitable for packaging loose, granular, or liquid products where gravity assists the filling process. Common applications include snack foods, agricultural products, and various industrial powders. The vertical configuration naturally saves valuable floor space in production facilities, a significant advantage for operations with limited square footage.

In contrast, horizontal (or pillow-type) packaging machines work laterally, making them the preferred solution for wrapping solid, pre-formed items. The horizontal orientation allows for precise positioning of products like chocolate bars, biscuits, soap tablets, or hardware components before they get enveloped in packaging material. This method creates the distinctive “pillow” shape that gives these machines their name. Industries ranging from confectionery to pharmaceuticals rely on horizontal packaging for its ability to neatly encase individual items while maintaining high production speeds.

The choice between these two packaging machine types ultimately depends on your specific product characteristics and production requirements. For businesses handling free-flowing materials that need to be measured and filled, vertical packaging machines typically offer better efficiency and accuracy. Their design allows for easier integration with filling systems and often provides simpler cleaning access – a critical factor for food-grade applications. Yuheng Technology’s vertical packaging solutions incorporate thoughtful design elements like quick-change bag size adjustments and stainless steel construction to meet international hygiene standards while maintaining competitive pricing advantages of Chinese manufacturing.

Horizontal packaging machines excel when dealing with solid items that require consistent positioning within each package. The longer conveyor systems characteristic of horizontal machines enable precise product alignment before wrapping, ensuring professional-looking packaging every time. This method proves particularly valuable for retail products where presentation matters. While requiring more floor space than vertical alternatives, horizontal packaging machines often achieve higher output speeds for suitable products, with some models reaching 300 packages per minute. Yuheng’s horizontal packaging equipment balances this productivity with energy-efficient operation and simplified maintenance access points.

Beyond the basic orientation differences, several practical considerations should guide your decision. Vertical packaging machines generally offer superior flexibility when handling various package sizes, as the bag-forming process adapts easily to different dimensions. They also tend to have fewer moving parts in the product contact areas, reducing cleaning complexity. Horizontal machines, meanwhile, provide better solutions for wrapping pre-made boxes or combining multiple items into a single package. The horizontal motion naturally accommodates these applications while maintaining excellent seal integrity.

Yuheng Technology designs both machine types with international operators in mind, featuring multilingual interfaces and compliance with major global safety standards. As a Chinese manufacturer with extensive export experience, we combine rigorous quality control with cost-effective production methods to deliver reliable packaging solutions at competitive price points. Our technical support team assists customers worldwide with machine selection, installation guidance, and ongoing maintenance advice to ensure optimal performance throughout the equipment lifecycle.

When evaluating packaging machinery options, consider not just the initial purchase price but also long-term operational factors. Vertical packaging machines typically show advantages in energy efficiency for suitable applications, while horizontal machines may offer labor savings for high-volume solid product packaging. Both types can be customized with various sealing options, printing capabilities, and quality control features to match specific production needs. Yuheng Technology’s engineering team works closely with clients to recommend the most appropriate configuration based on product characteristics, output targets, and facility parameters.

The packaging machinery sector continues evolving with smarter technologies, and both vertical and horizontal machines now incorporate features like remote monitoring and predictive maintenance alerts. These advancements help international buyers maintain consistent production quality across distributed manufacturing networks. Whether you choose vertical or horizontal packaging equipment, selecting a reliable manufacturer like Yuheng Technology ensures access to ongoing technical support and spare parts – critical factors for minimizing downtime in global operations.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us