Valve Bag Packaging Machine Price and Environmental Benefits

In today’s industrial landscape, two critical questions dominate powder packaging discussions: What is the investment range for valve bag packaging machines? and How do they address dust pollution while boosting productivity? As an innovative Chinese manufacturer, Yuheng Technology Co., Ltd specializes in developing valve bag packaging systems that perfectly balance economic value with environmental responsibility for global customers.

1. Comprehensive Price Guide for Valve Bag Packaging Machines

Entry-Level Solutions (¥100,000-¥250,000)

- Output: 200-400 bags/hour

- Perfect for: Small mineral processors and chemical producers

- Features: Semi-automatic operation with basic dust control

Mid-Range Production Systems (¥300,000-¥600,000)

- Output: 500-900 bags/hour

- Ideal for: Medium-sized cement plants and food additive manufacturers

- Includes: Advanced dust containment and touchscreen interface

Industrial-Grade Packaging Lines (¥700,000-¥1,500,000+)

- Output: 1,000-2,500 bags/hour

- Designed for: Large-scale titanium dioxide and PVC powder producers

- Technology: Fully automated with intelligent monitoring

All Yuheng systems feature:

✔ 3-year core component warranty

✔ <5mg/m³ dust emission standard

✔ 25% energy reduction technology

2. Environmental Protection and Efficiency Advantages

2.1 Dust Control Breakthroughs

Traditional powder packaging creates three major problems:

- Workplace contamination endangering staff health

- Product loss through spillage (5-15% typically)

- Environmental pollution violating green initiatives

Yuheng’s innovative solutions:

- Hermetic filling chamber with negative pressure

- Three-stage filtration (cyclone + bag filter + HEPA)

- Automatic cleaning system preventing filter clogging

2.2 Productivity Enhancements

Compared to manual packaging:

- 5-8 times faster processing speeds

- 99.5% weighing accuracy reducing material waste

- Continuous 24/7 operation capability

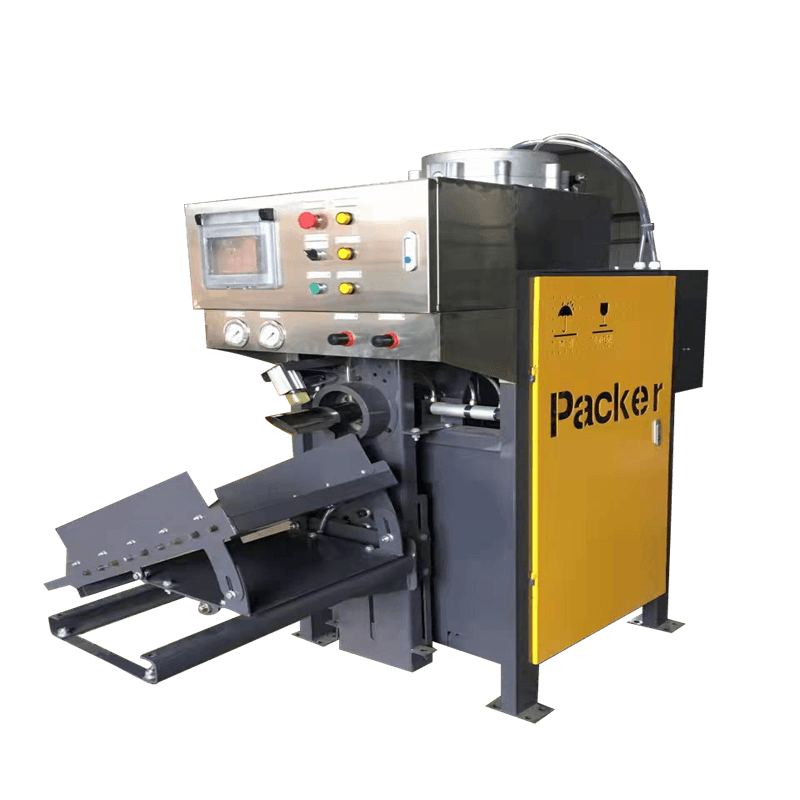

3. System Components and Workflow

Intelligent Packaging Process:

- Auto bag feeding – Precision positioning system

- Dust-free filling – Sealed weighing mechanism

- Vibration compaction – Uniform product density

- Ultrasonic sealing – No heat contamination

- Automatic palletizing – Robotic arm integration

Material-Specific Configurations:

- Fine powders (like talcum): Special anti-static design

- Coarse granules (like minerals): Heavy-duty auger system

- Hygroscopic materials: Nitrogen protection option

4. Why Global Customers Choose Yuheng

China Manufacturing Advantages:

- Cost efficiency: 30-40% savings over European brands

- Rapid customization: 2-3 week modification turnaround

- Strict quality control: ISO 9001 certified production

After-Sales Support Network:

- Online remote diagnostics

- Global spare parts inventory

- Multilingual operation manuals

Technical Highlights

✅ Dust Emission: <5mg/m³ (GB 16297 standard)

✅ Noise Level: ≤75dB (factory environment)

✅ Power Consumption: 20-35kW typical systems

✅ Bag Weight Range: 10-50kg standard models

If you want to know more about the equipment configuration and other details, please feel free to communicate with us