Valve Bag Packaging Machine Costs & Proven Strategies to Reduce Repairs

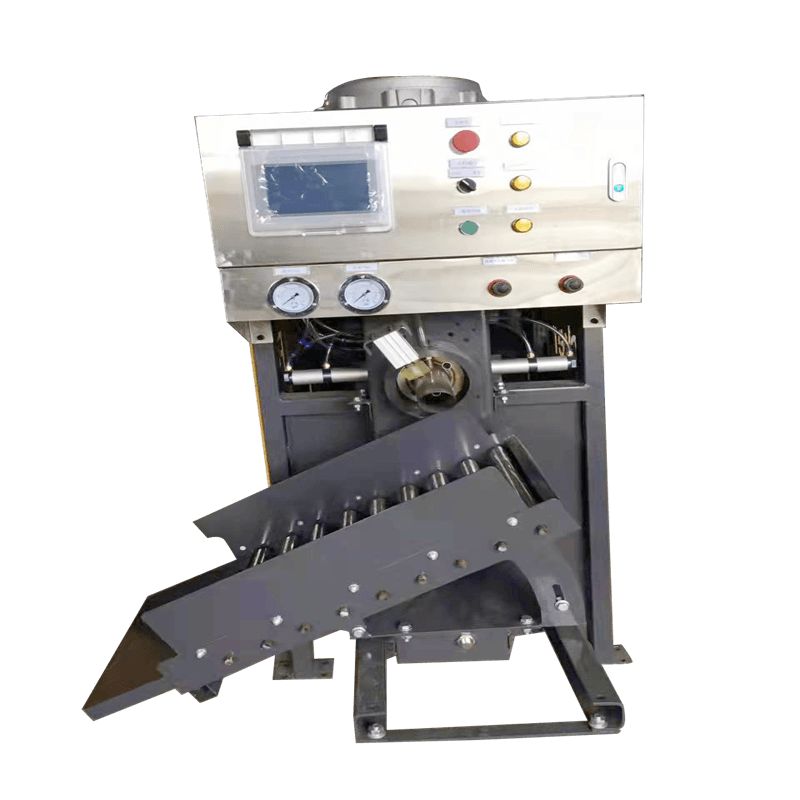

Valve bag packaging machines are indispensable in industries like cement, chemicals, and food processing, offering rapid filling and sealing for powdered or granular materials. However, two critical concerns dominate buyer decisions: What factors influence valve bag packaging machine prices? and How can businesses minimize costly repairs? Yuhang Technology Co., Ltd. (裕恒科技有限公司), a leading Chinese manufacturer, addresses these challenges by delivering robust, low-maintenance systems backed by China’s engineering expertise. Below, we analyze pricing variables and actionable maintenance strategies to maximize uptime.

Valve Bag Packaging Machine Price Ranges

Equipment costs range from $45,000 to $350,000, shaped by:

- Automation Level:

- Semi-automatic models (1–5 bags/minute): $45k–$80k

- Fully automated lines with robotic palletizing: $200k+

- Material Compatibility: Machines handling abrasive materials like fly ash require tungsten-carbide-coated spouts, adding 15–25% to costs.

- Dust Control Systems: ISO-compliant models with integrated air filtration cost 10–20% more but reduce environmental fines.

Yuhang Tech optimizes affordability through China’s vertically integrated supply chain. A Kenyan fertilizer producer saved 28% by choosing our modular system, which scaled from 3 to 12 bags/minute as their operations grew.

5 Data-Driven Methods to Slash Repair Frequency

1. AI-Powered Preventive Maintenance

Traditional manual inspections miss 40% of early wear signs. Yuhang Tech’s SmartCare System uses vibration sensors and thermal imaging to predict failures 72+ hours in advance. For example:

- Case Study: A Vietnamese cement plant reduced unplanned downtime by 65% after installing our IoT-enabled monitors, which detected misaligned auger bearings before catastrophic failure.

2. Operator Mastery Programs

Human error causes 30% of valve bagger malfunctions. Our 3-Tier Training Framework ensures:

- Level 1: Basic operation & emergency protocols (4-hour course)

- Level 2: Troubleshooting common issues (e.g., seal jams, sensor errors)

- Level 3: Predictive maintenance analytics

A Colombian coffee processor cut repair calls by 50% after certifying 80% of their staff through this program.

3. Strategic Spare Parts Inventory

Yuhang Tech’s Critical Component Kit includes:

- High-wear items: Filling spouts, gripper belts, torque motors

- Region-specific spares: Humidity-resistant circuit boards for tropical climates

Clients using our AI-driven inventory management tool reduced parts waste by 35% while maintaining 98% repair readiness.

4. Failure Pattern Analysis

Our cloud-based Repair Insights Platform tracks:

- Top 5 failure causes per machine type

- Mean Time Between Failures (MTBF) trends

- Costliest repair categories

A Moroccan phosphate producer eliminated 80% of recurring hydraulic leaks by analyzing 12 months of data and upgrading to our polymer-reinforced hoses.

5. Rapid-Response Service Networks

Yuhang Tech’s 24/7 Global Support guarantees:

- Remote diagnostics within 2 hours

- On-site repairs in 48–72 hours (90% of regions)

- Mobile repair units for remote sites

A Chilean copper miner avoided $220k in losses during a critical shipment by leveraging our emergency hotline to resolve a PLC fault in 5 hours.

Yuhang Tech’s Engineering Edge: Built to Last

As a Chinese manufacturer, we integrate regional operational insights into every valve bagger:

- Dust-Immune Designs: Triple-sealed bearings and IP67-rated electronics withstand cement/coal dust.

- Corrosion Defense: Electroplated frames resist chemical exposure in fertilizer plants.

- Energy Efficiency: Regenerative braking systems cut motor wear by 40% in start-stop cycles.

A case in point: An Indonesian palm oil mill extended their machine’s lifespan by 6 years using our tropicalized models, despite operating in 85% humidity.

Why Maintenance Strategy Impacts Total Costs

Neglecting proactive care leads to:

- 3–5x higher repair costs over 5 years

- 15–30% productivity loss from unscheduled stops

Yuhang Tech counters this through:

- Extended Warranties: Covering 90% of components for 3–5 years

- Performance Contracts: Guaranteeing <2% annual downtime for premium clients

Partner with China’s Valve Bagging Innovators

Understanding valve bag packaging machine prices and maintenance isn’t just about budgets—it’s about building resilient, future-ready operations. Yuhang Technology Co., Ltd. combines Chinese manufacturing efficiency with globally validated reliability, delivering systems that perform in the harshest environments. From mining giants to agro-processors, our clients achieve 40% fewer repairs and 20% longer machine life through intelligent design and data-driven care.

Contact us today to discover how our valve baggers can streamline your packaging line while keeping maintenance costs predictable and low.