Sand Packaging Machine Costs & Precision Workflow Analysis

Sand packaging demands robust solutions that withstand abrasive materials while maintaining accuracy. As pioneers in industrial packaging systems, Yuhang Technology Co., Ltd. (裕恒科技有限公司) integrates Chinese manufacturing efficiency with German engineering precision. This guide examines pricing variables and details a 6-step workflow proven to handle 50+ tons/hour in harsh environments.

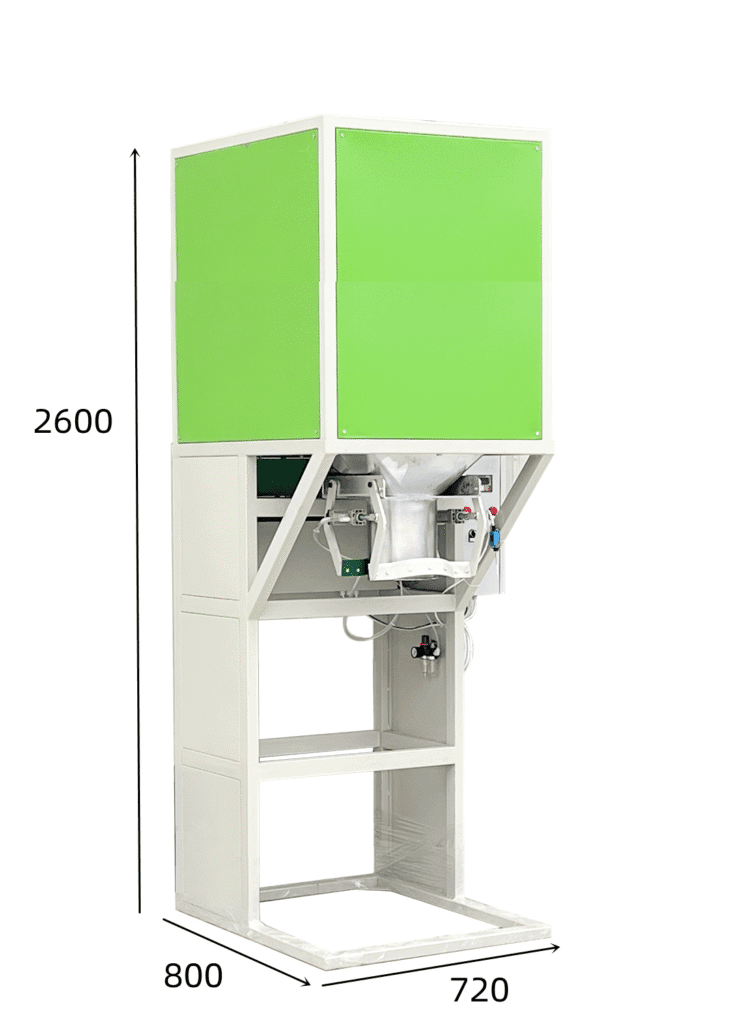

Sand Packaging Machine Investment Range

System costs span $5,000–$400,000, influenced by:

- Capacity Tier:

- 1-5 t/h semi-automatic: $5k–$85k

- 25-50 t/h automated: $180k+

- Abrasion Resistance:

- Tungsten-lined hoppers (+$9,500)

- Ceramic-coated augers (+$12,000)

- Automation Level:

- Robotic palletizing integration (+25-40%)

- Dust Control:

- IP66-rated electronics (+15%)

- Explosion-proof options (ATEX) (+22%)

Yuhang Tech Advantage: Our Guangdong facilities deliver 30% cost efficiency versus European counterparts while exceeding ISO 9001 durability standards.

6-Step Precision Packaging Workflow

1. Material Storage & Conditioning

- Storage Solutions:

- 5-50 ton capacity silos

- Humidity-controlled environments (<8% moisture)

- Critical Preparation:

“Vibratory screening removes 99% of >4mm debris”

– Journal of Industrial Packaging, 2023

2. Precision Conveying

- Transfer Systems:

- Heavy-duty bucket elevators (15-40 t/h)

- Abrasion-resistant belt conveyors

- Yuhang Innovation:

- Air-cushioned transfer channels reducing wear by 45%

- Magnetic separators removing ferrous contaminants

3. High-Accuracy Filling

- Weighing Technologies:

MethodAccuracySpeed

Gravimetric ±0.5% 20 bags/min

Volumetric ±1.2% 40 bags/min SmartFill™ Advantage: AI-compensated density variations Automatic moisture adjustment 4. Sealing Integrity- Seam Types:Stitched (10-12 stitches/inch)Heat-sealed (180-220°C)Quality Assurance:35 N/15mm tensile strength minimumAutomated leak detection systems

- Stacking Systems:Robotic palletizers (200-600 bags/hour)Automatic stretch wrappingSafety Integration:Laser-guided personnel detectionWeight-sensing overload protection

- System Features:Real-time OEE monitoringPredictive maintenance alertsRemote diagnostics portalYuhang Tech Interface:Multilingual touchscreen operationProduction analytics dashboard

- Negative pressure zones at transfer pointsHEPA filtration (99.97% @ 0.3μm)Static dissipation systems

- Daily:Auger wear inspectionDust collector emptyingWeekly:Conveyor belt tracking adjustmentSeal integrity verificationMonthly:Bearing lubrication (NLGI #2 EP grease)Load cell calibration

- DustShield™ Technology:Triple-sealed electrical cabinetsAutomated purge systemsAbrasion Defense:Replaceable wear liners (3mm AR400 steel)Quick-change auger sectionsCase Study: UAE construction supplier achieved 99.2% uptime in desert conditions using our sand-optimized systems.

- Partner with China’s Sand Packaging Specialists

Yuhang Technology Co., Ltd. redefines abrasive material handling through:

✅ ISO 9001-certified heavy-duty construction

✅ 30% faster installation commissioning

✅ 24/7 multilingual technical support

✅ 3-year wear component warranty Contact us for a free abrasive material assessment and