Description

Introduction of Feed Pellet Production Line

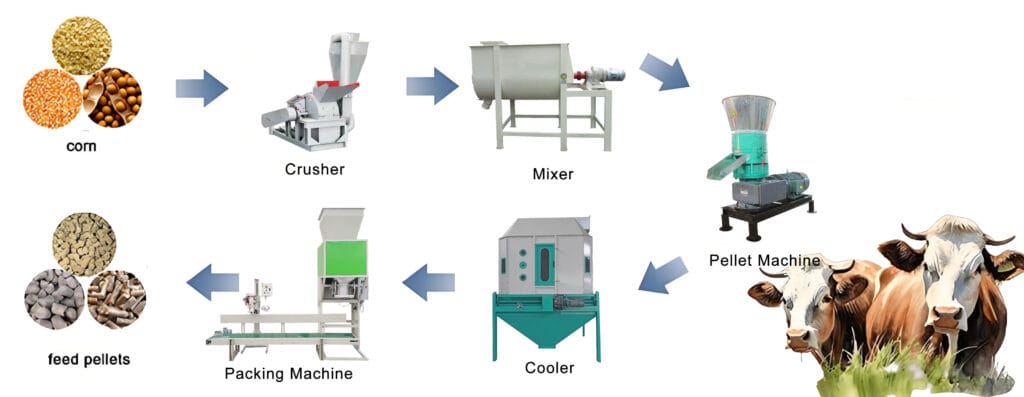

Animal feed pellet production line has very mature technology to make various poultry feed and aquatic feed such as cattle, chickens, sheep, rabbits, ducks, pigs, pigeons, fishes and shrimp etc. The whole poultry feed production plant can be control by the automatic PLC control system,which generally consisted of hammer mill, mixer, feed pellet

mill, cooler, packing machine, etc.

Steps of Feed Pellet Production Line

Step 1: Grinding

If your materials content grass or straw which with long fibre,the first step is to crush the raw materials.This stage is mainly to grind materials into fine powder so as it becomes easy while mixing them.They undergo a grinding process with the help of feed crusher machine powered by large motors. The crushed materials then moves up a conveyor to

reach its storage location in mixer machine.

Step 2: Mixing

Second step of is raw materials mixing. Mixing is one of the important operations in feed pellet processing.Lack of proper mixing may lead to reduced diet uniformity, affecting the feed pellet quality.The mixer churns the various components into a homogeneous mixture. Afterward, you can add the minerals compounds that you need for your animals,which can improve the feed pellet quality.

Step 3: Pelleting

The third step is raw materials pelleting.The materials after mixing need to be sent to the feed pellet machine for pelleting. The pellet process is the core step of whole production line, so it is necessary to monitor and timely deal with any abnormal conditions.

There are two common kind of feed pellet machine: flat die feed pellet mill and ring die feed pellet mill. If your demand is small capacity, you can choose the flat die feed pellet mill. If you want to produce feed pellets in commercial production, the ring die feed pellet mill is the ideal choice.

Step 4: Cooling

The produced pellets that have a moisture content of about 17%. Those hot pellets are conveyed through a cooler which reduces their moisture content and hardens the pellets. These are critical factors that prevent spoilage and breakage after packaging. The screen shaker will removes powder or broken pellet before the pellets are stored in preparation for either bulk sales or packaging.

Step 5: Packaging

Packing is the last stage of small chicken feed plant.In order to make the finished granules easy to store, transport and catch the customer’s eyes, they should be properly packaged. It will be done by a weighing and packing machine.The finished granules can be automatically packaged, weighed, conveyed and sealed, saving manpower and time and meeting the needs of large-scale production.

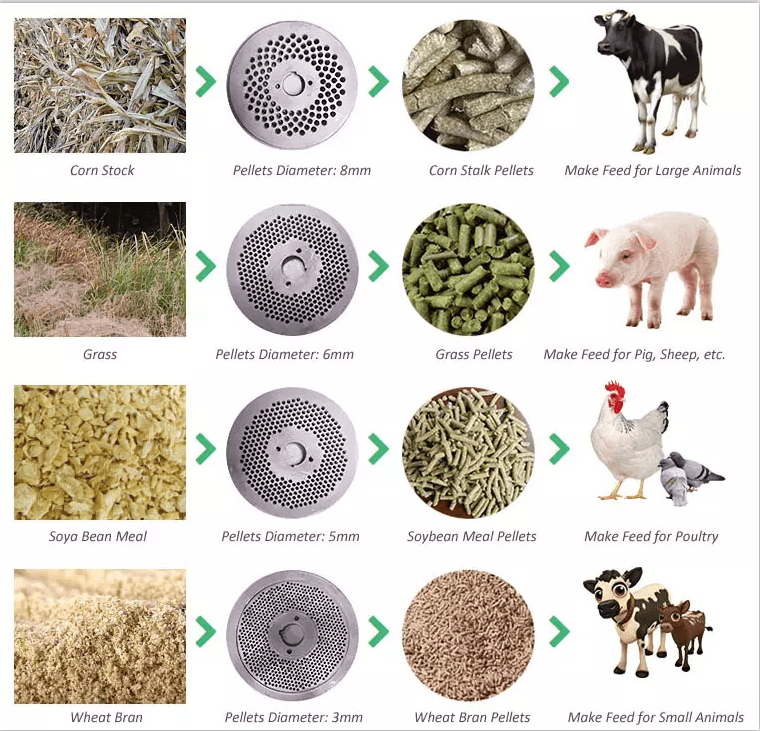

Raw Materials of Feed Pellet Production Line

Corn, maize, soybean, rice, wheat: contain about 10-14% of protein and also contain vitamin B1, B2, B6 and small quantity of enzyme. Rapeseed Meal, cotton seed meal: high protein-containing material that can be used as a feed for livestock and poultry. Typical meal contains around 38% of protein; however it also contains about 12% crude fiber and glucosinolates, specific components of cruciferae plants straw meal, grass meal, rice bran, wheat chaff: contain fiber, control many types of fish diseases.

Applications of Feed Pellet Production Line

Processing grain into pellets like corn/maize, soybean, rice, wheat, and no need crushing them before pelleting, put them in the pelleting room of animal feed making machine, they will become pellets automatically.

Making animal feed and livestock feed like for cattle feed pellet, chicken feed pellet, pig feed pellet, goat feed pellet, duck feed pellet, cattle feed pellet, horse feed pellet, bird feed pellet, and rabbit feed pellet etc and other animals and livestock.

Turning straw, grass, hay meal into pellets for animal feed and heating fuel.

Processing life garbage and other green plants into pellets for livestock and animal feed.

Reviews

There are no reviews yet.