Description

Introduction of Organic Fertilizer Production Line

The powdery organic fertilizer production line is one of the simple organic fertilizer production lines, also known as small-scale organic fertilizer production lines. The powdery organic fertilizer production line is suitable for many small farms, and its configuration is dehydration, drying, fermentation, crushing, mixing, and packaging. The technological process is to ferment, decompose, crush, mix and package organic fertilizer raw materials, animal manure or domestic garbage, sludge, distiller’s grains, biogas residue, etc., so as to complete the processing of powdered organic fertilizer.

We provide profitable fertilizer business ideas for new investors in the organic fertilizer field. If you want to start a fertilizer business, it is wiser to choose a small-scale plant that is simple to start and manage without too much stress and trouble. What is more, small-scale organic fertilizer plant is with a very low initial investment.

This mini organic fertilizer production plant is very suitable for organic fertilizer production investors who are beginning in the fertilizer field. Its production capacity is 500-1000kg per hour. Through the organic fertilizer production process (organic fertilizer machine), make organic fertilizer pellets or granules using livestock and poultry manure, straw, rice husk, biogas, sludge, food waste, and urban waste, both to reduce environmental pollution and reuse organic matter.

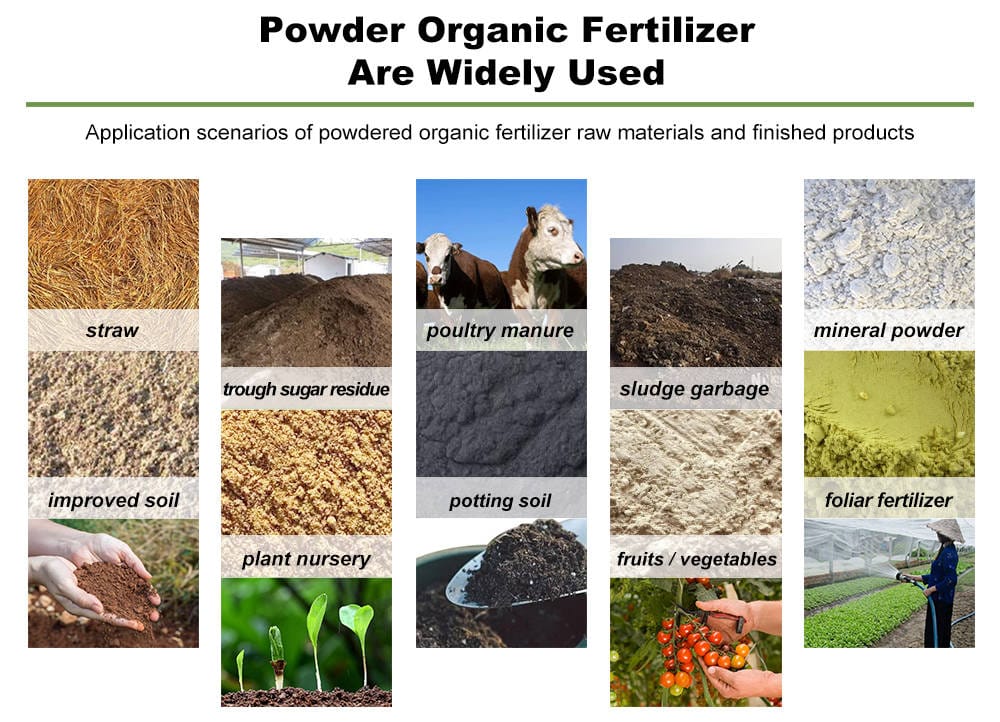

Suitable Raw Materials

According to local conditions, you can choose suitable raw materials.

(1) Manure: chicken manure, pig manure, cow dung, sheep manure, horse manure, rabbit manure, quail manure, pigeon dung and other animal manure;

(2) Straw: corn straw, corncob, straw, wheat straw, bean straw, sweet potato straw, grain stalk, etc.;

(3) Cakes: bean cake, soybean meal, oil cake, rapeseed cake, peanut cake, sesame cake, etc.;

(4) Sludge: domestic sludge, sugar mill filter, paper sludge, etc.;

(5) Adding raw materials: plant growth regulators, synergists, anti-caking agents, colorants, brighteners, binders, medium and trace elements, a large number of elements, carrier materials.

A

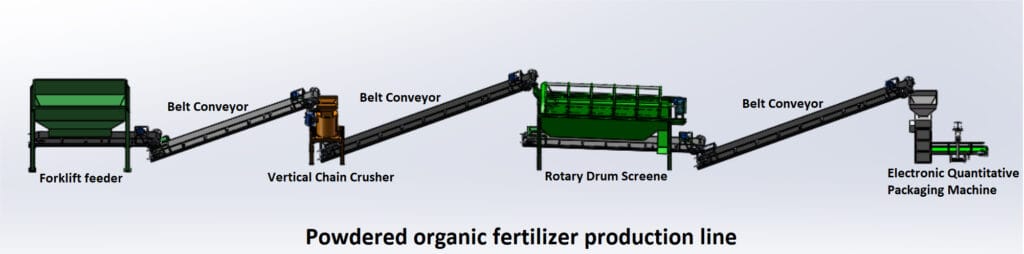

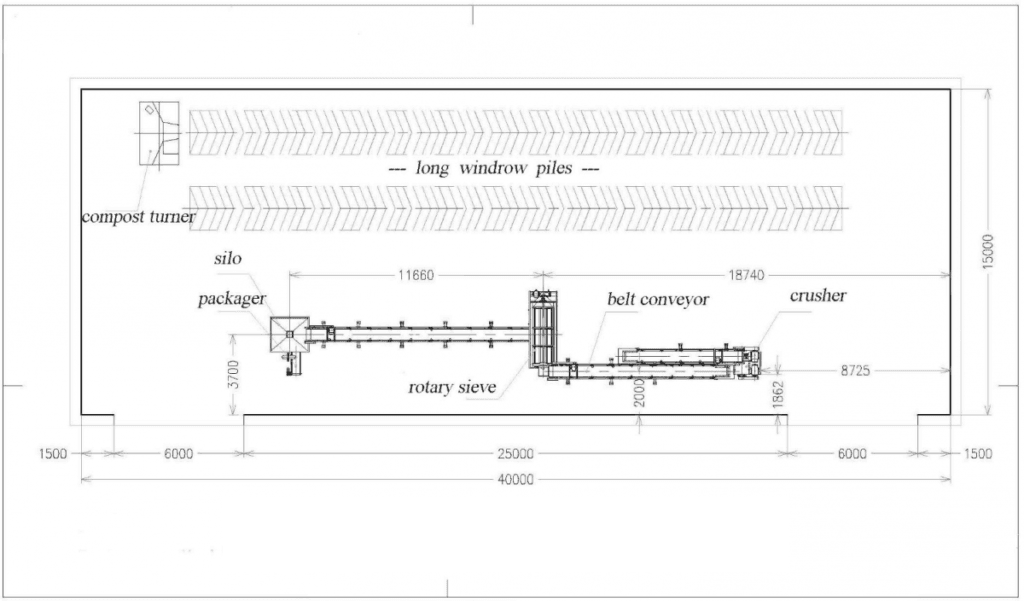

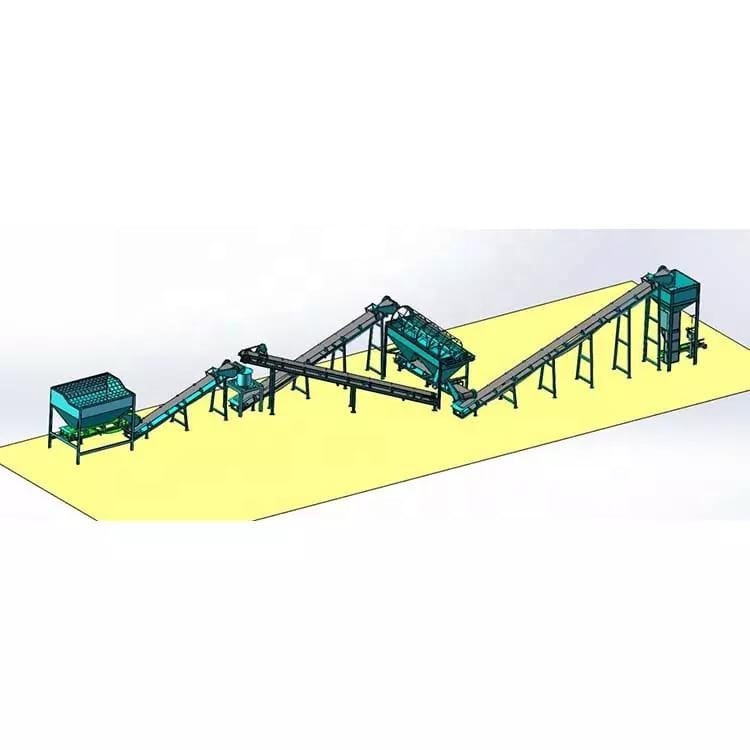

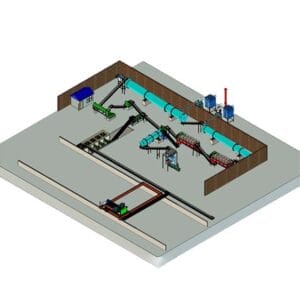

Structure of Organic Fertilizer Production Line

Working principle

Powdered organic fertilizer production process: compost – crushing – sieve – packaging.

* Compost

Organic raw materials are regularly carried out through the dumper. There are several parameters that affect compost, namely particle size, carbon-nitrogen ratio, water content, oxygen content and temperature. Attention should be paid to:

1. Crush the material into small particles;

2. The carbon-nitrogen ratio of 25-30:1 is the best condition for effective composting. The more types of incoming materials, the greater the chance of effective decomposition is to maintain the appropriate C:N ratio;

3. The optimal moisture content of compost raw materials is generally about 50% to 60%, and Ph is controlled at 5.0-8.5;

4. The roll-up will release the heat of the compost pile. When the material decomposes effectively, the temperature decreases slightly with the overturning process, and then returns to the previous level within two or three hours. This is one of the powerful advantages of the dumper.

* Smash

A vertical strip grinder is used to crush compost. By crushing or grinding, blocky substances in compost can be decomposed to prevent problems in packaging and affect the quality of organic fertilizer.

* Sieve

The roller sieve machine not only removes impurities, but also selects unqualified products, and transports compost to the sieve machine through a belt conveyor. This process process is suitable for drum sieve machines with medium size sieve holes. Sieving is indispensable for the storage, sale and application of compost. Sieving improves the structure of compost, improves the quality of compost, and is more beneficial to subsequent packaging and transportation.

* Packaging

The sieved fertilizer will be transported to the packaging machine to commercialize powdery organic fertilizer that can be directly sold through weighing, usually with 25 kg per bag or 50 kg per bag as a single packaging volume.

Feature of Organic Fertilizer Production Line

Biological organic fertilizer project is featured with Short-period construction, high investment repayment rate, low risk and short payback period. Organic fertilizer production technology use the newest special equipment and technology to process all kinds of organic wastes – farm’s livestock manure, the organic wastes of plants, agricultural wastes, sludge, residual leftovers, the sugar mill wastes into the green and protecting environmental fertilizer( bio-organic fertilizer).

Reviews

There are no reviews yet.