Description

Introduction of Bag Packing Line

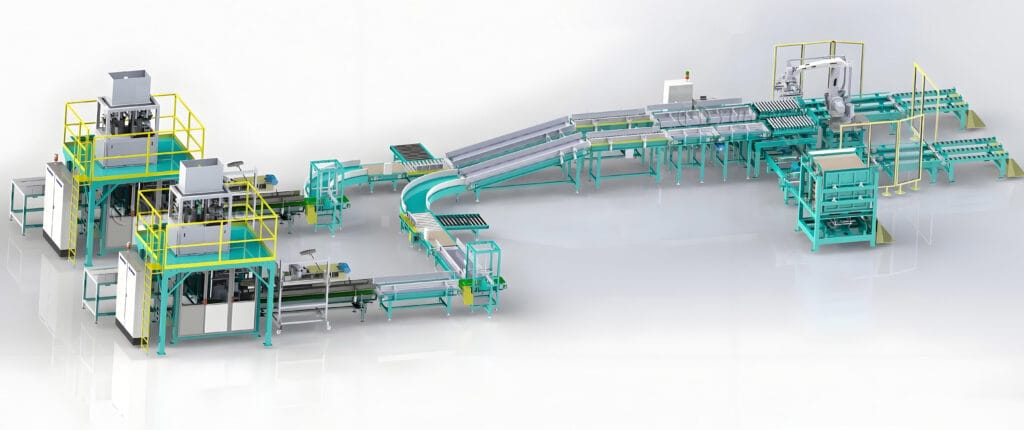

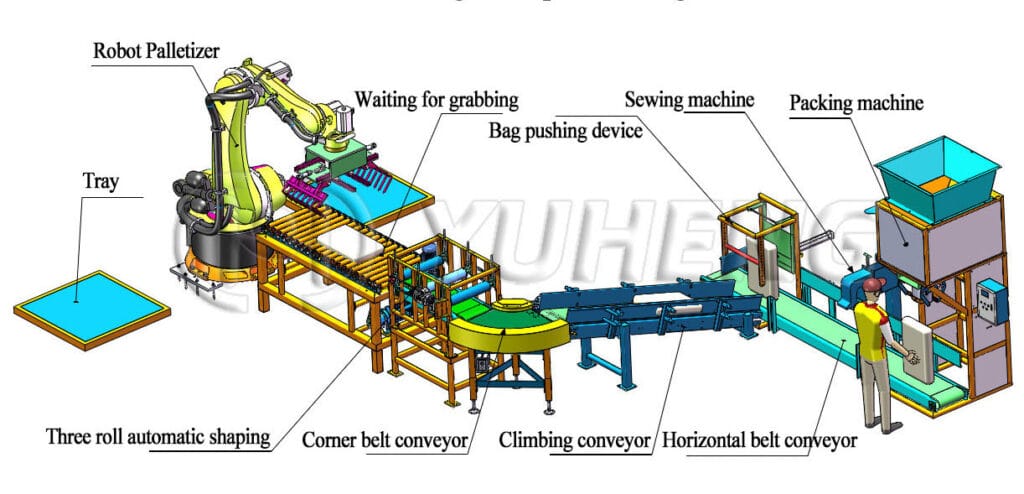

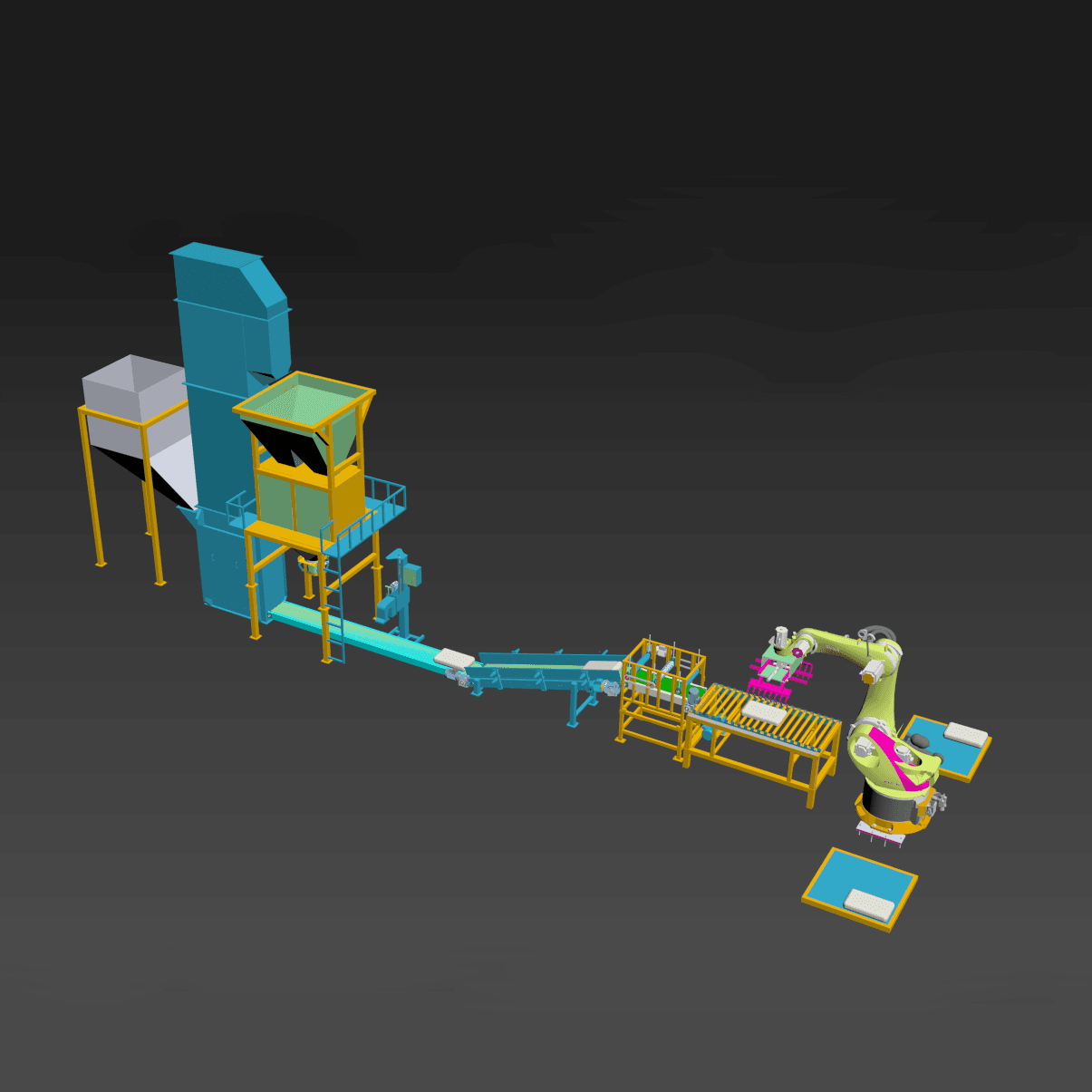

The packaging and palletizing production line is an indispensable part of the modern manufacturing and logistics industries, involving the packaging and automated palletizing of goods. With the booming development of e-commerce and the upgrading of the manufacturing industry, enterprises are increasingly demanding efficient and accurate packaging and palletizing solutions. The main function of this production line is to package products through automated equipment and palletize the packaged products neatly and efficiently for easy handling and storag

Structure of Bag Packing Line

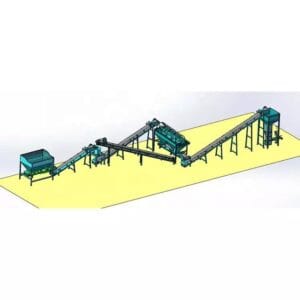

Conveying system

The products to be packaged are transported to the packaging area through various conveyors (such as belt conveyors and bucket elevators) to ensure the continuity and efficiency of the production process.

Packaging machine

According to the different types of products, choose the appropriate packaging machine (such as semi-automatic packaging machine, fully automatic packaging machine, etc.) to achieve fast and accurate packaging of products. Automatic packaging machines can improve production efficiency and reduce human errors.

Sealing system

The sealing machine is responsible for sealing the packaging bag. According to the different types of products, choose the appropriate sealing method (such as sewing machine, heat sealing, etc.) to ensure that the product will not leak or deteriorate during transportation and storage.

Palletizing machine

The palletizer adjacent to the packaging machine uses a robotic arm or stacking device to neatly stack the packaged products for easy storage and handling.

Product Feature of Bag Packing Line

1. Efficient automation: High degree of automation greatly reduces manual intervention, improves production efficiency and packaging quality.

2. Flexible adaptability: Can adapt to the packaging needs of various products, flexibly adjust equipment configuration to meet the needs of different production lines.

3. High precision: Precise weighing and detection system ensures the accuracy of packaging quality and quantity, and reduces production losses.

4. Energy saving and environmental protection: The design of modern equipment follows environmental protection principles, reduces energy consumption and material waste, and meets the requirements of sustainable development.

5. Improving competitiveness: The efficiency and quality improvement of the entire production line can effectively reduce the production costs of enterprises and enhance market competitiveness.

Product Pictures of Bag Packing Line

Reviews

There are no reviews yet.