Pricing and Selection Criteria for Pre-Made Pouch Packaging Systems

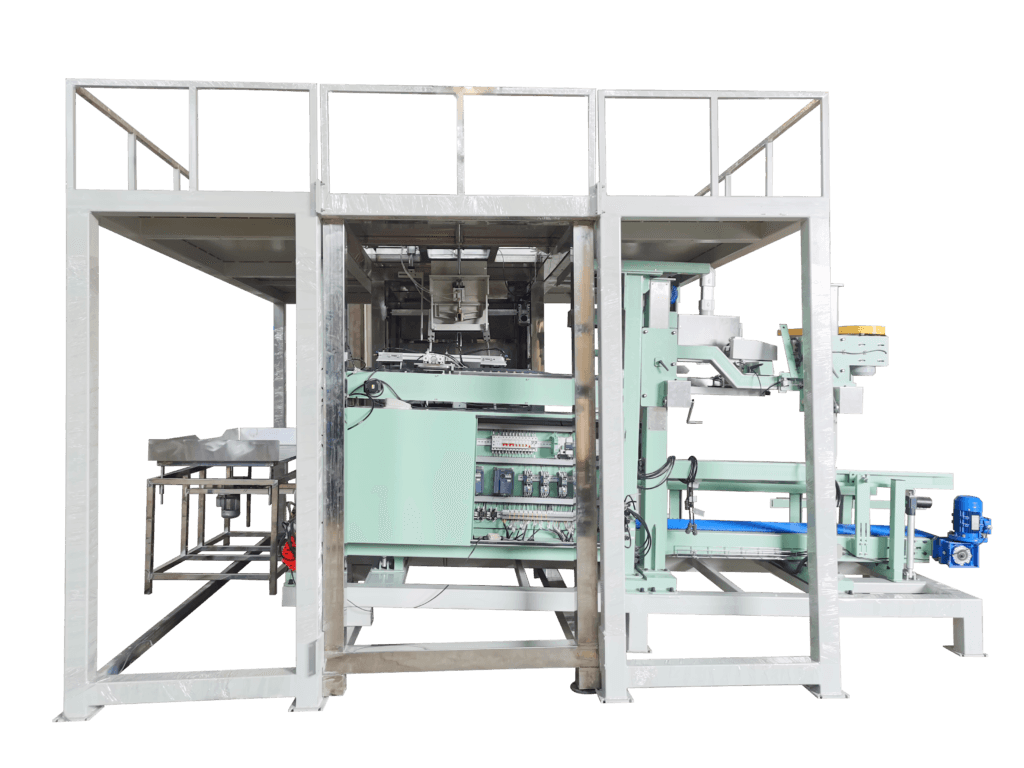

Pre-made pouch packaging machines have become vital solutions for food, pharmaceutical, and consumer goods industries. As a specialized manufacturer, Yuheng Technology offers intelligent systems that balance cost efficiency with operational flexibility, demonstrating China’s expertise in practical automation solutions.

Cost Considerations

Equipment pricing typically ranges from $3,000 to $300,000 depending on speed requirements (20-120 pouches/minute) and customization needs. Chinese-engineered systems like Yuheng’s models provide 25-40% cost advantages through localized component sourcing and modular designs.

6 Essential Selection Principles

1. Material Compatibility

Evaluate pouch types (stand-up/gusseted/pillow) and product characteristics. Our systems handle various materials including laminated films and biodegradable alternatives, with adjustable sealing jaws accommodating 100-500g pouch sizes. Specialized models manage challenging products like viscous sauces or fragile snacks.

2. Throughput Matching

Base speed selection on production volumes and line integration needs. Yuheng’s mid-range models (60 pouches/minute) suit most SME operations, while high-speed versions integrate with upstream filling systems for large-scale production. Consider future capacity expansion through upgradeable designs.

3. Operational Flexibility

Look for quick-change components reducing format switch time below 30 minutes. Our patented magnetic fixture system enables tool-free adjustments for different pouch dimensions, supported by preset configuration profiles for common packaging types.

4. Automation Level

Prioritize systems with integrated vision inspection and rejected pouch removal. Advanced models feature AI-powered defect detection achieving 99.5% accuracy, significantly reducing manual quality checks. Yuheng’s automatic film feeding systems maintain continuous operation with minimal supervision.

5. Build Quality

Inspect critical components like heat seal bars and servo motors. Our machines utilize Japanese-grade stainless steel contact surfaces and EU-certified electrical components, ensuring 20,000+ hour service life in humid environments.

6. Support Infrastructure

Verify supplier technical support capabilities. Yuheng maintains regional service centers providing:

- 48-hour emergency response

- On-site operator training programs

- Transparent spare parts pricing

Yuheng Technology’s Competitive Advantages

- Adaptive Sealing Technology: Automatic temperature compensation maintains seal integrity across materials

- Energy Efficiency: Regenerative drives reduce power consumption by 35%

- Smart Maintenance: IoT-enabled platforms predict bearing failures 500 operating hours in advance

Industry Application Trends

Recent market analysis shows:

- Snack food manufacturers achieve 30% faster time-to-market with flexible systems

- Pharmaceutical companies report 98.7% batch consistency using vision-guided models

- Sustainable packaging adoption drives demand for biodegradable material compatibility