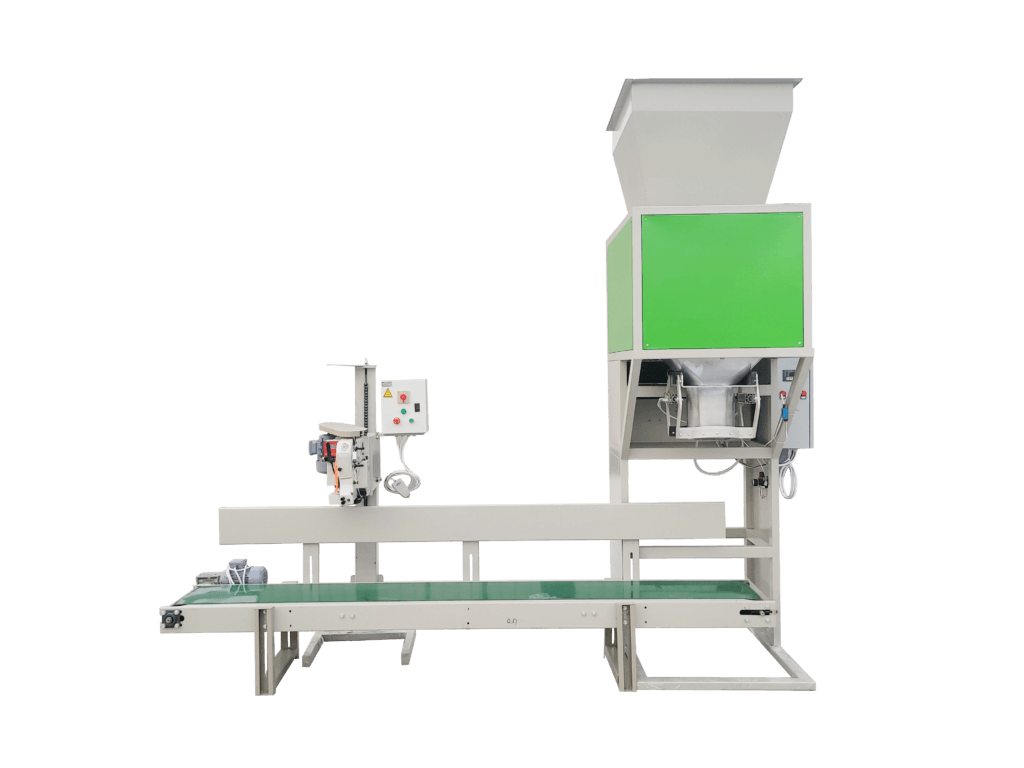

Price Guide for Granule Packaging Machines & Preventive Maintenance Protocol

1. Granule Packaging Machine Price Range

Market prices vary by configuration:

- Entry-level: $15,000-$35,000 (semi-auto, 50-120 bags/min)

- Mid-range: $35,000-$80,000 (auto weighing, 120-300 bags/min)

- Industrial-grade: $80,000+ (with robotic integration, 300-600 bags/min)

Key cost determinants:

- Weighing accuracy: ±0.1% premium models vs ±1% standard

- Material contact: 316L stainless steel adds 15-20% cost

- Special requirements: Explosion-proof versions cost 30% more

2. Critical “No Sick Operation” Maintenance Plan

(1) Pre-Shift Safety Checklist

- Conduct 5-minute test run (listen for abnormal vibrations >4mm/s)

- Verify emergency stops response time (<0.5s activation)

- Check sealing temperature stability (±2℃ tolerance)

(2) Scheduled Maintenance

| Interval | Action Items |

|---|---|

| Daily | Clean residual granules, inspect belts tension |

| Weekly | Lubricate chains, calibrate load cells |

| Monthly | Replace worn gaskets, check electrical insulation |

| Quarterly | Overhaul transmission system, update firmware |

(3) Warning Signs of “Sick Operation”

- Production abnormalities: 5%+ increase in defective packages

- Performance drift: 10% slower than rated speed

- Energy spikes: 15% higher power consumption

3. Cost of Neglect vs Preventive Care

- Reactive maintenance: $120+/hour emergency repairs + $500+/day downtime

- Preventive program: <$0.10/operating hour (extends lifespan 3-5 years)

Proven Maintenance ROI:

- 60-70% reduction in unplanned downtime

- 40-50% longer component lifespan

- 30% lower energy consumption

Operational Tip: Maintain digital logbooks tracking:

- Hourly production counts vs ideal capacity

- Weekly maintenance compliance rates

- Monthly component wear measurements

If you want to know more about the equipment configuration and other details, please feel free to communicate with us