Powder Packaging Machine Pricing & Maintenance: How to Extend Equipment Lifespan

Powder packaging machines play a vital role in industries ranging from pharmaceuticals to food processing, ensuring accurate dosing and sealing for products like spices, medicines, and nutritional supplements. While upfront costs are a primary concern for buyers, proper daily maintenance is equally critical to maximizing equipment longevity and ROI. As a trusted Chinese manufacturer, Yuhang Technology Co., Ltd. (裕恒科技有限公司) designs user-friendly, cost-effective powder packaging systems that simplify upkeep while adhering to global quality standards. Below, we break down pricing factors and actionable maintenance strategies to help you protect your investment.

What Determines Powder Packaging Machine Prices?

Prices typically range from $2,000 to $300,000, influenced by:

- Automation Level: Basic semi-automatic models suit small batches, while fully automated lines with touchscreen controls cater to high-volume production.

- Material Compatibility: Machines handling abrasive powders (e.g., ceramics) require hardened steel components, increasing costs by 20–35%.

- Certifications: FDA-compliant or ISO 22000-certified systems cost 10–25% more but streamline exports to regulated markets.

Yuhang Tech addresses these variables through China’s scalable manufacturing ecosystem. For example, a Kenyan dairy producer saved 18% by choosing our modular machine, which allowed phased upgrades from manual to AI-driven filling.

5 Essential Maintenance Practices to Prolong Equipment Life

1. Systematic Cleaning Protocols

Residual powders, especially hygroscopic materials like protein supplements, can clog mechanisms or corrode parts. Yuhang Tech’s machines feature removable stainless steel hoppers and accessible seams to simplify cleaning. A Southeast Asian client reduced downtime by 40% using our anti-corrosion models with integrated air-blowing systems, which auto-remove dust after each cycle.

2. Precision Lubrication Schedules

Over-lubrication attracts contaminants, while under-lubrication accelerates wear. Our IoT-enabled dispensers (optional upgrade) automatically apply food-grade grease to bearings and chains at optimal intervals. A Colombian coffee processor reported a 30% drop in part replacements after adopting this system.

3. Proactive Component Inspections

- Weekly: Check belt tension, electrical connections, and sealing jaws.

- Monthly: Test load cells for weighing accuracy and inspect pneumatic valves.

Yuhang Tech’s machines include QR-coded maintenance guides on critical parts, enabling technicians to access repair tutorials via smartphone—a feature praised by clients in remote areas.

4. Timely Calibration Adjustments

Vibration or temperature changes can misalign sensors. Our self-diagnostic control panels alert operators to recalibrate fill volumes or sealing temperatures. A Moroccan pharmaceutical company improved dosing accuracy by 99.2% using this feature.

5. Avoiding Overload Through Smart Scheduling

Continuous operation strains motors and increases heat buildup. Yuhang Tech’s energy-saving mode automatically reduces motor speed during idle periods, cutting energy use by 25% and extending component life.

Yuhang Tech’s Design Innovations Simplify Maintenance

As a Chinese manufacturer, we integrate regional operational challenges into our designs:

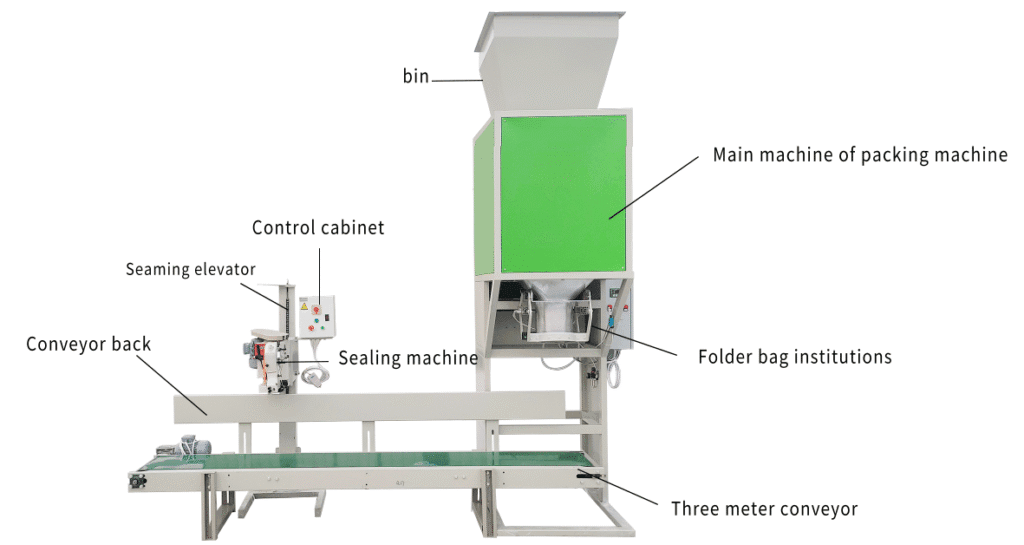

- Modular Components: Swap worn parts like augers or film feeders in minutes.

- Unified Lubrication Ports: Service multiple bearings through a single access point.

- Corrosion-Resistant Coatings: Protect machines in humid climates like coastal regions.

A case in point: A Vietnamese seasoning producer extended their machine’s lifespan by 5 years using our salt-resistant models, despite operating in a high-humidity facility.

Why Maintenance Impacts Total Ownership Costs

Neglecting upkeep can lead to:

- 50–70% higher repair costs over 3 years

- 15–30% productivity loss from unplanned downtime

Yuhang Tech counters these risks through:

- Annual Maintenance Contracts: Remote diagnostics and priority spare parts delivery.

- Operator Training Programs: On-site or virtual sessions to teach cleaning and troubleshooting.

Partner with China’s Packaging Efficiency Experts

Understanding powder packaging machine prices and maintenance isn’t just about budgets—it’s about building resilient operations. Yuhang Technology Co., Ltd. combines Chinese manufacturing efficiency with globally compliant engineering to deliver machines that last. From agro-businesses to pharmaceutical giants, our clients achieve up to 40% longer equipment lifespans through proactive care and intelligent design.

Contact us today to discover how our powder packaging solutions balance affordability, durability, and ease of maintenance—all while keeping your production line running smoothly.