Powder Packaging Machine Price Guide & Leakage Solutions

How Much Does a Powder Packaging Machine Cost?

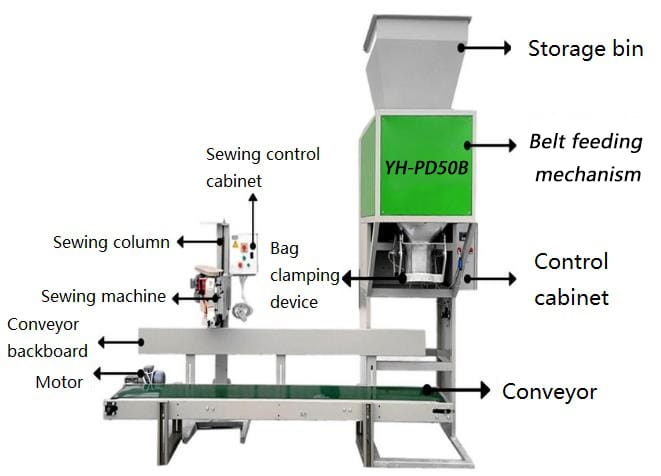

Powder packaging machines are essential equipment in pharmaceutical, food, and chemical industries, designed to precisely pack powdered materials into sealed bags. As a leading packaging machine manufacturer in China, Yuheng Technology provides high-quality powder packaging machines that ensure accuracy, efficiency, and minimal waste.

Price Range for Powder Packaging Machines

The cost varies depending on specifications, but generally falls within:

- Basic Semi-Automatic Models: $10,000–$25,000

- Suitable for small-scale production (200–500 bags/hour)

- Ideal for food spices, protein powders, and non-hazardous chemicals

- Mid-Range Automatic Machines: $25,000–$60,000

- Higher speed (500–1,000 bags/hour)

- Enhanced sealing systems for pharmaceuticals and fine powders

- High-Speed Fully Automated Systems: $60,000–$120,000+

- Industrial-grade production (1,000–2,000 bags/hour)

- Advanced features like multi-head weighers and robotic bag handling

Why Choose Yuheng Technology?

✔ Cost-Effective Manufacturing – As a Chinese OEM, we offer competitive pricing without compromising quality.

✔ Precision Engineering – Our machines achieve ±0.2% dosing accuracy, reducing material waste.

✔ Custom Solutions – Adjustable for different powders (e.g., flour, pharmaceuticals, titanium dioxide).

How to Solve Powder Leakage Issues?

Powder leakage is a common problem that affects product quality and production efficiency. Below are the key causes and solutions based on our 10+ years of industry experience.

1. Machine Inspection & Maintenance

Problem:

- Loose components, misaligned seals, or worn-out parts can cause leaks.

Solution:

✔ Daily Checks – Inspect sealing jaws, gaskets, and filling nozzles for wear.

✔ Preventive Maintenance – Replace damaged parts immediately (Yuheng provides long-lasting spare parts).

✔ Stability Test – Ensure the machine runs smoothly without excessive vibration.

2. Optimizing Operational Parameters

Problem:

- Incorrect vibration intensity, filling speed, or bag positioning leads to spillage.

Solution:

✔ Adjust Vibration Frequency – Too much vibration shakes powder out; too little causes uneven filling.

✔ Calibrate Filling Nozzle Height – Prevents powder from scattering during transfer.

✔ Test Different Speeds – Some powders (like talc) require slower filling to avoid dust clouds.

3. Improving Bag Sealing Quality

Problem:

- Weak seals due to poor heat/pressure settings or low-quality packaging films.

Solution:

✔ Upgrade Sealing Material – Use multi-layer laminated films for better airtightness.

✔ Optimize Heat Seal Settings – Adjust temperature (150–220°C) based on film thickness.

✔ Add Sealant (If Needed) – Food-grade adhesives can reinforce seams for fine powders.

4. Environmental & Powder-Specific Factors

Problem:

- Static electricity, humidity, or powder characteristics (e.g., ultra-fine consistency) worsen leakage.

Solution:

✔ Anti-Static Nozzles – Prevent powder from clinging to surfaces.

✔ Dehumidifiers – Control moisture in the packaging area.

✔ Specialized Filling Systems – Yuheng’s anti-dust suction nozzles minimize spillage for lightweight powders.

Yuheng Technology’s Leak-Proof Packaging Solutions

✅ Dual-Layer Sealing System – Combines heat and pressure for 99.9% seal integrity.

✅ Smart Sensors – Detect and correct filling errors in real time.

✅ Easy-Clean Design – Reduces cross-contamination risks in pharmaceutical applications.

Conclusion

Choosing the right powder packaging machine and maintaining it properly prevents leakage issues. Yuheng Technology offers:

✔ Reliable, leak-resistant machines with advanced sealing tech

✔ Cost savings via efficient Chinese manufacturing

✔ 24/7 technical support for troubleshooting

Contact us for a free consultation and quote!