Powder Packaging Machine Costs & Solving Temperature Overheating Issues

Powder packaging machines face unique challenges when handling fine materials like pharmaceuticals, milk powder, or spices—with overheating being a critical operational risk. As a leader in thermal management solutions, Yuhang Technology Co., Ltd. (裕恒科技有限公司) combines cost-effective engineering with intelligent cooling systems. Below, we break down pricing variables and diagnose four root causes of temperature spikes with actionable solutions.

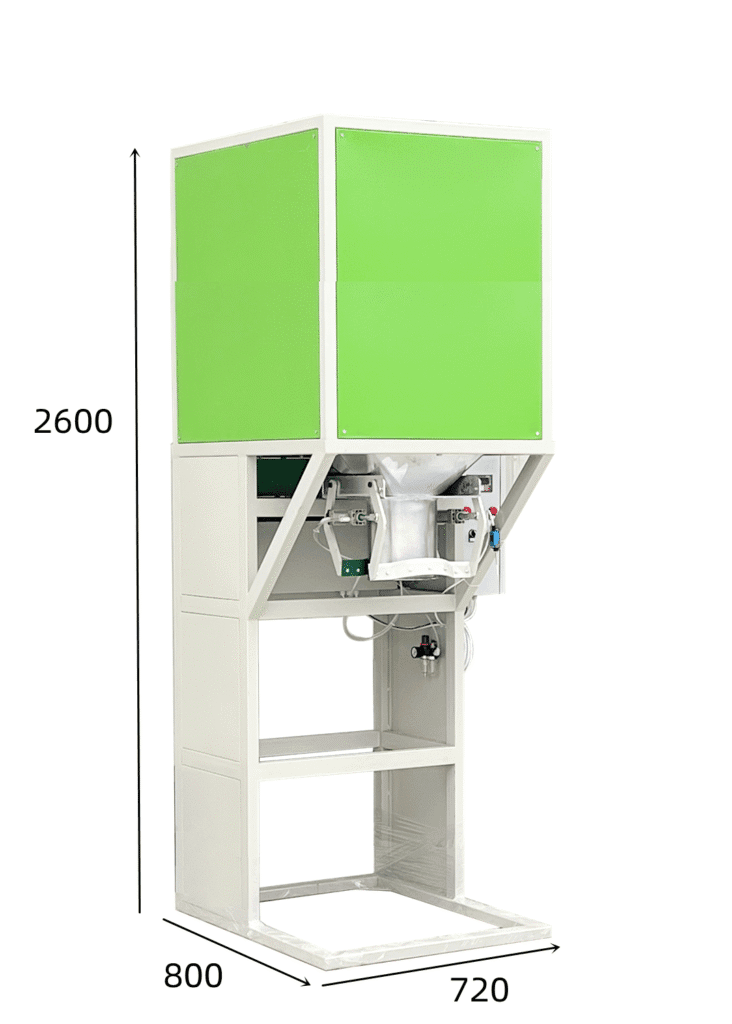

Powder Packaging Machine Price Guide

Equipment costs range from $2,000 to $280,000, influenced by:

- Thermal Management Tier:

- Basic models: $2k–$75k

- Advanced liquid-cooled systems: $150k+

- Material Sensitivity: Machines handling heat-sensitive powders (e.g., enzymes) require precision temperature controls (+25% cost).

- Speed Rating: High-capacity units (>200 packs/min) demand enhanced cooling.

Yuhang Tech leverages China’s manufacturing scale to deliver 30% cost efficiency. A Vietnamese spice processor saved $38,000 using our modular T-Cool™ series, scaling production without overheating risks.

4 Root Causes of Overheating & Proven Solutions

1. Ambient Temperature Stress

- Risk Threshold: Operation above 35°C ambient

- Consequences:

- Sealant failure (+23% defect rate)

- Motor insulation degradation

- Yuhang Tech Solutions:

- Integrated air-curtain isolation (rejects 80% external heat)

- Tropicalized models for Southeast Asian/Middle Eastern climates

Case Study: Nigerian pharmaceutical plant reduced shutdowns by 70% using our climate-adaptive units in 42°C environments.

2. Cooling System Failures

- Critical Components:

- Compressor efficiency losses

- Radiator clogging (dust accumulation)

- Coolant leaks

- Diagnostic Protocol:

- Thermal imaging scans (detect >5°C variance)

- Flow sensors monitoring coolant circulation

- Repair Solutions:

- Modular radiator swaps (<45 minutes)

- Auto-purge systems preventing dust clogs

3. Operational Overloading

- Safety Thresholds:

- Max. 18 hours continuous runtime

- 85% motor load capacity

- Warning Signs:

- >60°C motor housing temperature

- Irregular power consumption spikes

- Prevention Strategies:

- AI-driven load balancing (adjusts speed during peaks)

- Auto-shutdown at 65°C critical threshold

Client Data: Chilean dairy producer eliminated overheating using our SmartCycle™ scheduling (22% energy savings).

4. Thermal Insulation Failure

- Common Fault Points:

- Degraded heater band insulation

- Worn thermal gaskets

- Loose wiring connections

- Maintenance Protocol:

- Monthly resistance checks (insulation >1 MΩ)

- Replace gaskets at 5,000-hour intervals

- Yuhang Tech Innovation:

- Ceramic-fiber insulation layers (withstand 800°C)

- Self-tightening terminal blocks

Yuhang Tech’s Thermal Management Edge

As a Chinese manufacturer, we pioneer solutions for extreme conditions:

- 3-Stage Cooling Architecture: Combines air/fluid/Peltier cooling

- Real-Time Monitoring: Touchscreens display zone temperatures (±0.5°C accuracy)

- Dust-Immune Design: Sealed electronics compartments (IP66 rating)

Proof Point: Indonesian spice packer achieved zero heat-related stops for 24 months using our humidity-resistant systems.

When to Seek Professional Support

Contact Yuhang Tech immediately if:

⚠️ Temperatures exceed 70°C at critical components

⚠️ Frequent thermal error codes (E05/E17 series)

⚠️ Unusual odors or smoke emissions

Our global response network guarantees:

- 2-hour remote diagnostics

- 48-hour on-site support (85% regions)

- Priority spare parts delivery

Partner with China’s Thermal Control Experts

Understanding powder packaging machine costs and overheating solutions ensures uninterrupted production. Yuhang Technology Co., Ltd. merges Chinese manufacturing efficiency with German-grade precision engineering, delivering machines that perform in the harshest environments.

Why Global Clients Choose Us:

✅ ISO 9001-certified thermal systems

✅ 40% faster heat dissipation vs. industry average

✅ 5-year critical component warranty

Request a free thermal audit today and discover how our powder packaging solutions balance performance with reliability—proving China’s engineering excellence in action.