Packaging Machinery Costs & 6 Essential Operational Protocols

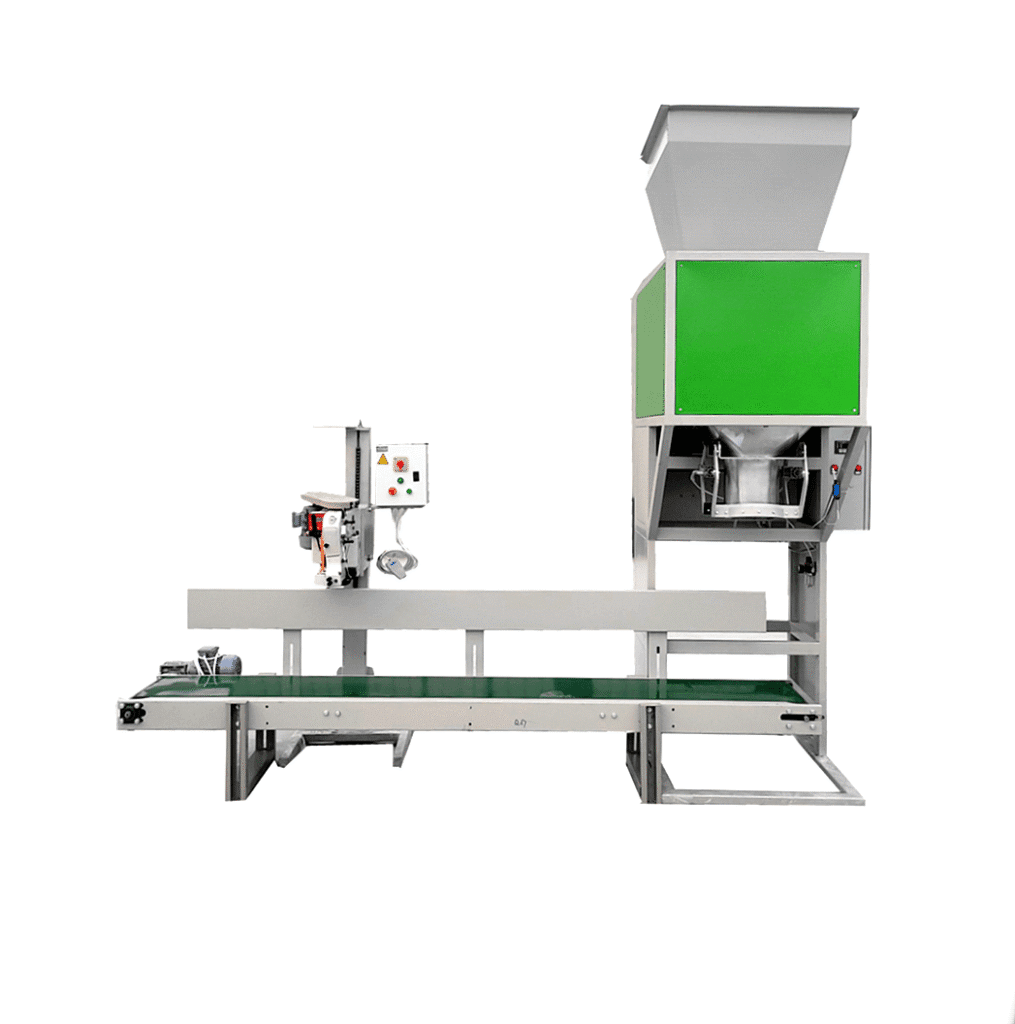

Operating packaging machinery efficiently requires mastering both cost considerations and critical safety protocols. As an ISO-certified Chinese innovator, Yuhang Technology delivers high-performance systems while prioritizing operational safety. This guide examines pricing variables and details vital handling procedures for risk-free production.

Packaging Machinery Investment Range

Equipment costs range from $2,000–$500,000 based on:

| Configuration | Throughput | Price |

|---|---|---|

| Semi-automatic | 30 units/min | $2k–$65k |

| Fully automated | 200+ units/min | $180k+ |

| Hybrid systems | Custom output | $75k–$150k |

Yuhang Advantage: 30% lower ownership costs with 45-day rapid customization

6 Critical Operational Protocols

1. Comprehensive System Familiarization

- Pre-Operation Essentials:

● Study equipment manuals (QR-code access)

● Complete virtual reality simulations

● Verify safety certification tags - Yuhang Feature: Interactive 3D operation guides

2. Safety-First Operation Framework

- Mandatory Protocols:

● Lockout-tagout (LOTO) implementation

● Anti-entanglement uniforms (snag-free design)

● Emergency stop testing (<0.4s response) - Risk Prevention: Magnetic proximity sensors halt machinery near limbs

3. Load Management System

- Capacity Monitoring:

Machine Type Max Capacity Alert Threshold

Filling 25kg 22kg

Sealing 500N 450N

Conveying 1t/hour 900kg - Smart Solution: Auto-shutdown at 95% load capacity

- 4. Sequential Operation Compliance

- Critical Workflow:

[Power On]-->[System Check]-->[Parameter Set]-->[Warm-up Cycle]-->[Production Start]- Yuhang Innovation: Step-locked control panel

- Material-Specific Settings:

Material Seal Temp Speed

Plastics 180-220°C 20/min

Foils 150-170°C 35/min

Composites 190-210°C 25/min

- Adjustment Tip: Gradual 10% increments

- 6. Proactive Maintenance Regimen

- Daily Essentials:

● Lubrication point inspection (15+ zones)

● Dust removal from optics/sensors

● Seal integrity verification

- Daily Essentials: