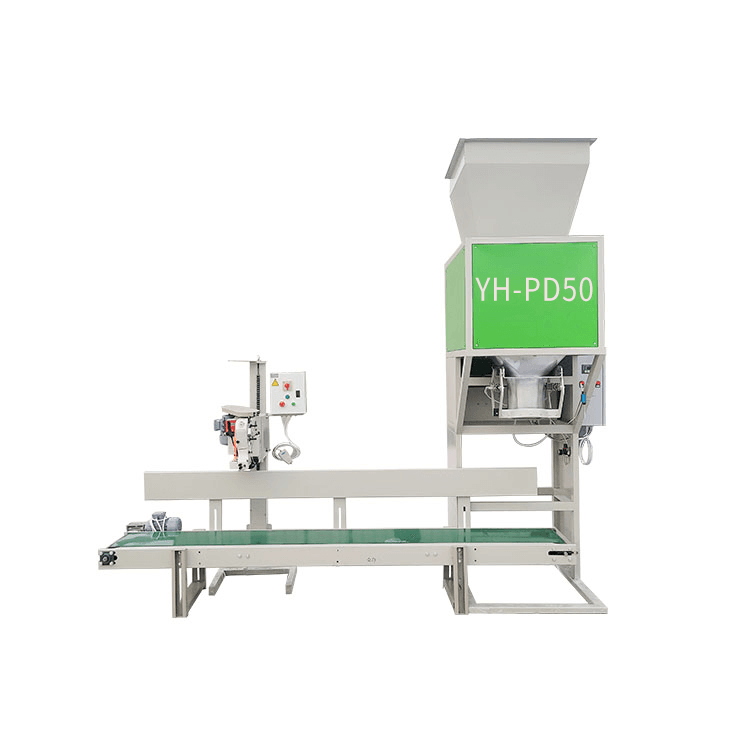

Packaging Machine Pricing & 6 Common Failure Causes with Prevention Strategies

Understanding packaging machine costs and failure patterns is crucial for maintaining production efficiency. Yuhang Technology Co., Ltd. (裕恒科技有限公司) combines Chinese manufacturing reliability with advanced diagnostics to minimize downtime. This analysis breaks down pricing variables and proven solutions for common operational failures.

Packaging Machine Price Ranges

Equipment investments span $28,000–$850,000, influenced by:

- Automation Level:

- Semi-automatic: $2k–$75k

- AI-integrated lines: $250k+

- Durability Features:

- Abrasion-resistant coatings (+15-22%)

- IP66-rated electronics (+12%)

- Throughput Capacity:

- 50 units/min: $4k–$90k

- 300+ units/min: $400k+

Yuhang Tech Advantage: Our Guangdong facilities deliver 30% cost efficiency with ISO 9001-certified quality control.

6 Primary Failure Causes & Preventive Solutions

1. Component Degradation (Aging)

- High-Risk Parts:

- Sealing jaws (replace every 500k cycles)

- Drive belts (lifespan: 8,000–10,000 hrs)

- Yuhang Solution:

- WearSensor™ Technology: Embedded RFID tags alert at 80% lifespan

- Modular replacement kits (30-min swaps)

2. Operational Errors

- Common Mistakes:

- Overriding safety interlocks

- Incorrect speed settings for materials

- Prevention Protocol:

- Touchscreen with password-protected limits

- AR-guided operation manuals

Chilean food processor reduced errors by 70% using Yuhang’s training simulators

3. Inadequate Maintenance

- Critical Oversights:

- Delayed bearing lubrication (+300% failure risk)

- Dust accumulation in electrical panels

- SmartCare® System:

- Automated lubrication reminders

- Self-diagnostic air purge cycles

4. Material Contamination

- Failure Triggers:

- Moisture >8% in powders

- Metal fragments (>0.5mm)

- Yuhang Safeguards:

- In-line moisture sensors

- Magnetic separators at intake points

5. Power Instability

- Damage Thresholds:

- Voltage spikes >±15%

- Phase imbalance >2%

- Protection Systems:

- Automatic voltage regulators

- Surge-protected control cabinets

6. Environmental Stress

- Risk Factors:

ConditionFailure Rate Increase

>85% humidity 40%

>40°C ambient 55%

Dust >5mg/m³ 65% - Yuhang Innovations: Tropicalized corrosion protection HEPA filtration systems

- Failure Impact AnalysisIssueDowntime CostPrevention ROI Electrical failure $550/hr <8 months Seal degradation 25% waste increase <5 months Bearing seizure 48-hr repair <3 months

- Yuhang Tech’s Proactive Approach Chinese engineering excellence delivers:

- Climate-Adaptive Designs:Humidity-resistant control systemsDesert-grade airfiltration

- Predictive Diagnostics:Vibration analysis algorithmsThermal imaging integration

- Case Study: Vietnamese spice plant achieved 99.1% uptime in monsoon season using our protected systems

Yuhang Technology Co., Ltd. minimizes failures through:

✅ 40% longer component lifespans

✅ 24/7 remote diagnostics

✅ 5-year critical parts warranty

✅ Localized spare parts networks Contact us for a free machine health assessment and experience