Packaging Machine Price Guide and Comprehensive Solutions to Prevent Abnormal Vibrations

Introduction to Modern Packaging Machinery Solutions

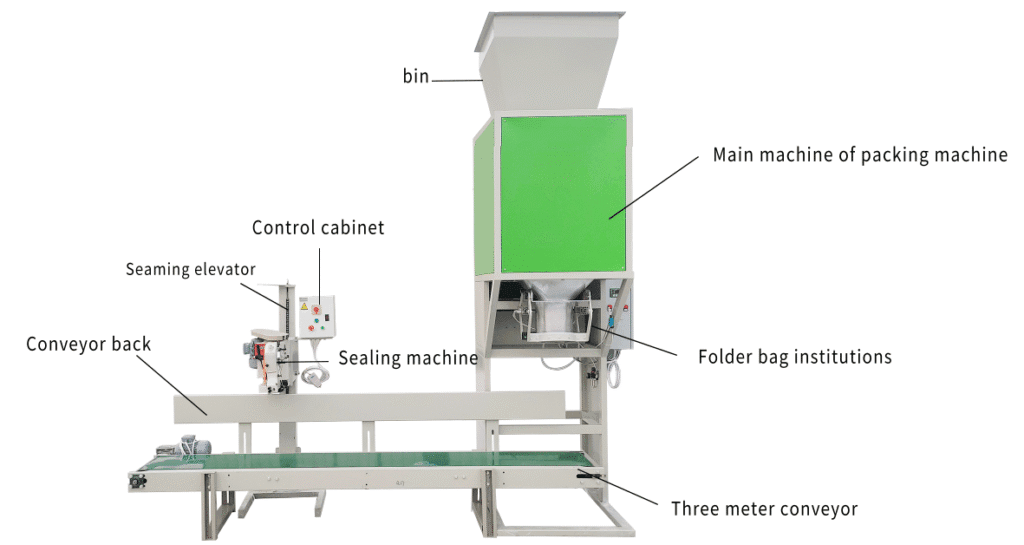

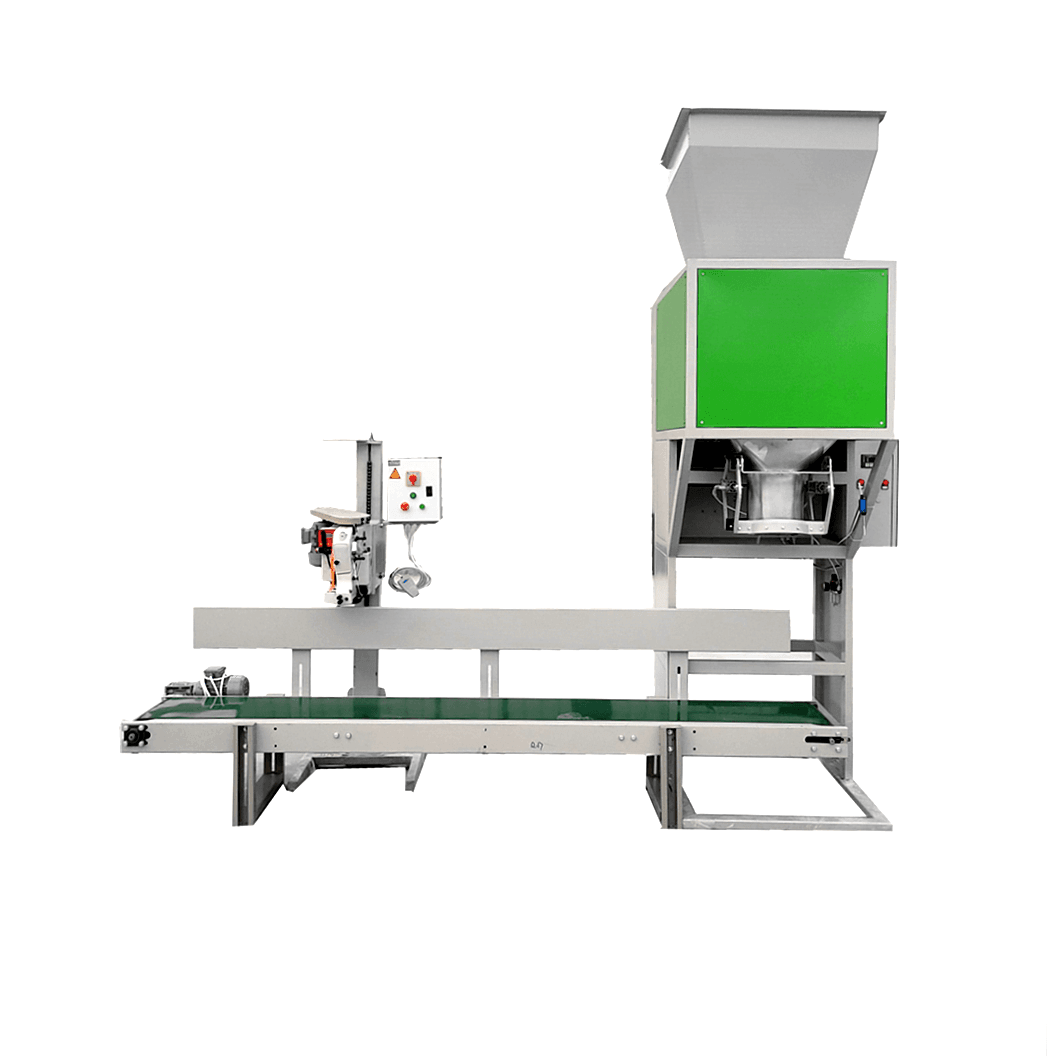

In today’s fast-paced industrial environment, packaging machines have become indispensable equipment for businesses across multiple sectors including food processing, pharmaceutical manufacturing, and consumer goods production. These sophisticated systems not only enhance operational efficiency but also ensure product consistency and quality throughout the packaging process. As an established leader in packaging technology with over 15 years of manufacturing expertise, Yuheng Technology Co., Ltd has emerged as a trusted global provider of high-performance packaging solutions that combine innovative engineering with the competitive advantages of Chinese manufacturing. Our machines are designed to meet the rigorous demands of international markets while offering exceptional value through efficient production processes.

Detailed Pricing Breakdown for Packaging Machinery

Understanding the investment required for packaging equipment is crucial for making informed purchasing decisions. The price range for packaging machines varies significantly based on their automation level, production capacity, and specialized features. Entry-level semi-automatic models represent the most accessible option for small to medium-sized operations, typically priced between $15,000 and $45,000. These systems offer basic packaging functionality with production capacities ranging from 20 to 50 packages per minute, making them ideal for businesses with moderate packaging needs or those looking to automate their processes for the first time. While requiring more operator involvement than fully automated systems, they provide an excellent balance between functionality and affordability.

For growing businesses with higher production demands, mid-range automatic packaging systems offer enhanced capabilities at price points ranging from $45,000 to $120,000. This category features more advanced technology including touchscreen control panels, improved weighing accuracy (±0.5%), and basic vibration damping mechanisms. With production capacities between 50 and 100 packages per minute, these machines are particularly well-suited for operations that require consistent output while maintaining flexibility for different packaging formats. The increased automation in these models significantly reduces labor requirements while improving overall packaging consistency.

At the premium end of the spectrum, high-speed automated packaging lines represent the pinnacle of packaging technology, with prices ranging from $120,000 to over $300,000 depending on configuration. These sophisticated systems incorporate cutting-edge features such as robotic integration, advanced vibration control systems, and pharmaceutical-grade accuracy (±0.2%). Capable of processing 100 to 200+ packages per minute, they are designed for large-scale industrial operations where maximum throughput and precision are critical. Yuheng Technology takes particular pride in our ability to deliver these high-end systems with the reliability and performance expected by global customers, while maintaining the cost advantages of our Chinese manufacturing base.

Advanced Strategies for Vibration Prevention and Control

Optimal Installation and Foundation Preparation

The foundation upon which a packaging machine is installed plays a critical role in its long-term performance and vibration characteristics. Proper installation begins with selecting an appropriate location featuring a solid, level concrete floor with sufficient load-bearing capacity. Yuheng Technology recommends conducting a thorough site assessment prior to installation to identify any potential vibration sources in the surrounding environment. Our machines are designed with integrated vibration-damping mounts that significantly reduce operational vibrations, but we also advise customers to consider supplemental anti-vibration solutions such as isolation pads or inertia bases for particularly sensitive applications. Ensuring adequate clearance space around the machine not only facilitates proper airflow for cooling but also prevents vibration transmission to adjacent equipment.

Comprehensive Maintenance and Component Management

Implementing a robust preventive maintenance program is essential for minimizing vibration-related issues throughout the equipment’s service life. Yuheng packaging machines are designed with maintenance accessibility in mind, featuring strategically placed inspection points and easily replaceable components. We recommend establishing a detailed maintenance schedule that includes monthly inspections of all critical components including bearings, gears, and drive systems. Particular attention should be paid to identifying early signs of wear in high-stress components, as addressing these issues promptly can prevent more serious vibration problems from developing. Our technical support team can assist customers in developing customized maintenance protocols tailored to their specific operating conditions and production requirements.

Precision Alignment and Drive System Optimization

The alignment of drive system components has a direct and significant impact on a packaging machine’s vibration characteristics. Even minor misalignments in motors, shafts, or belt drives can generate substantial vibration forces that compromise both equipment performance and product quality. Yuheng machines undergo rigorous alignment verification during manufacturing, but we emphasize the importance of periodic realignment checks in the field. Our engineering team has developed straightforward alignment procedures that can be performed using basic tools, supported by detailed instructional materials provided with each machine. Proper belt tension maintenance is another critical factor in vibration control, and our systems include clear tension indicators to simplify this important maintenance task.

Intelligent Load Management and Operational Best Practices

Operating packaging equipment within its designed capacity parameters is fundamental to maintaining smooth, vibration-free performance. Each Yuheng packaging machine comes with clearly specified load limits that have been carefully determined through extensive testing. Our systems incorporate intelligent load monitoring features that provide operators with real-time feedback on machine performance, helping to prevent accidental overloading situations. We also train customers on proper product distribution techniques to ensure even loading across the machine’s working surfaces. Implementing smooth start-up and shutdown procedures, avoiding sudden speed changes, and monitoring motor temperature trends are all operational practices that contribute significantly to vibration reduction and overall equipment longevity.

Systematic Lubrication and Component Care

Proper lubrication practices form the cornerstone of effective vibration prevention in packaging machinery. Yuheng Technology provides detailed lubrication schedules specific to each machine model, specifying the appropriate lubricant types and application intervals for all critical components. Our machines feature strategically placed lubrication points designed for easy access during routine maintenance. We emphasize the importance of cleaning lubrication surfaces before applying fresh lubricant to prevent contamination buildup that could accelerate component wear. For customers operating in challenging environments, we offer specialized lubrication solutions designed to maintain optimal performance under extreme temperature conditions or in the presence of dust and moisture.

Operator Training and Performance Monitoring

Well-trained operators are the first line of defense against vibration-related issues in packaging operations. Yuheng Technology includes comprehensive operator training with every machine purchase, covering not only basic operation but also vibration recognition and basic troubleshooting techniques. Our training programs emphasize the importance of monitoring for early signs of vibration problems, such as unusual noises or changes in packaging consistency. We provide multilingual training materials and can arrange on-site training sessions to ensure operators develop the skills needed to maintain optimal machine performance. For customers with multiple shifts, we recommend implementing a knowledge transfer system to ensure consistent operating practices across all teams.

Yuheng Technology’s Engineering Excellence in Vibration Control

Our commitment to vibration reduction begins at the design stage, where we incorporate multiple proprietary technologies to ensure smooth, stable operation. All Yuheng packaging machines feature dynamically balanced rotating components that minimize inherent vibration sources. The frame structures of our machines utilize advanced shock-absorbing designs that effectively dampen operational vibrations before they can affect packaging quality. We employ precision alignment techniques during assembly to ensure all drive systems operate with minimal vibration. Our engineering team continuously refines these technologies based on field performance data collected from our global customer base, allowing us to deliver packaging solutions that meet the most demanding vibration control requirements.

Selecting the Optimal Packaging Solution

Choosing the right packaging machine requires careful consideration of both current needs and future growth plans. Yuheng Technology’s packaging specialists work closely with customers to analyze their specific requirements including product characteristics, production volume targets, available facility space, and operator skill levels. We consider factors such as the physical properties of the products being packaged, including their size, weight, and flow characteristics, as these can all influence vibration behavior during operation. Our consultation process includes detailed facility assessments to identify potential vibration sources in the production environment and recommend appropriate mitigation strategies. Whether you’re looking for a basic semi-automatic system or a fully automated packaging line, we can guide you to the optimal solution that balances performance, reliability, and value.

Conclusion and Next Steps

Investing in quality packaging equipment and implementing proper vibration control measures delivers substantial long-term benefits including extended equipment life, reduced maintenance costs, and improved product quality. Yuheng Technology stands ready to partner with your business to develop packaging solutions tailored to your specific requirements. Our combination of engineering expertise, rigorous quality control, and cost-effective Chinese manufacturing enables us to deliver exceptional value to customers worldwide. We invite you to contact our packaging specialists today to discuss how our solutions can enhance your operations while ensuring vibration-free performance for years to come. Let us show you why businesses around the world trust Yuheng Technology for their packaging needs, and discover how our commitment to innovation and quality can benefit your organization.