Open-Mouth Bag Packaging Machine Costs: 6 Key Selection Factors

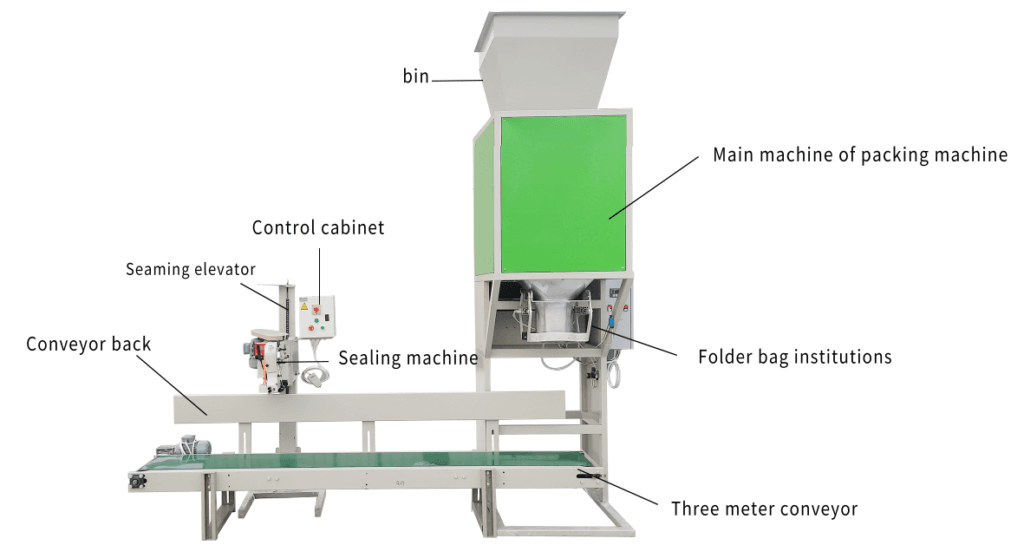

Open-mouth bag packaging machines are essential for industries handling bulk materials like grains, fertilizers, and industrial powders. Balancing cost and functionality requires careful evaluation of technical and operational needs. Below, we simplify pricing insights and selection criteria to help businesses make informed decisions.

Open-Mouth Bag Packaging Machine Pricing Overview

Equipment costs scale with automation and specialization:

- Basic semi-automatic models: $2,000–$45,000 (10–25 bags/hour)

- Mid-range automated systems: $50,000–$110,000 (30–60 bags/hour)

- Custom solutions: $130,000+ (hazardous materials, IoT integration)

Chinese manufacturers like YU-HENG Technology offer 20–35% cost advantages over Western brands while maintaining ISO-certified quality.

6 Critical Selection Factors

1. Material Characteristics

- Flowability: Free-flowing pellets work with standard augers, while cohesive powders need vibration-assisted feed systems.

- Abrasiveness: Highly abrasive materials (e.g., mineral ores) require hardened steel components.

- Dust control: Fine powders demand integrated vacuum systems.

Example: A Southeast Asian rice mill opted for corrosion-resistant stainless steel to handle humid grain packaging.

2. Packaging Specifications

| Parameter | Standard Range | Customization Options |

|---|---|---|

| Bag capacity | 10–50 lb (4.5–22.7 kg) | Up to 100 lb (45 kg) |

| Bag dimensions | 12″–24″ (30–61 cm) width | Oversized formats (+30% cost) |

3. Automation Level

- Manual/Semi-auto: Ideal for low-volume, multi-SKU operations.

- Fully automated: Reduces labor by 70% via robotic bag placement and sealing.

- Smart systems: IoT-enabled models provide real-time production analytics.

4. Sealing Method Compatibility

- Heat sealing: 300–450°F (149–232°C) for poly-lined bags.

- Stitching: Heavy-duty thread for rugged materials like animal feed.

- Cold seal: Pressure-sensitive adhesives for heat-sensitive products.

5. Reliability & Brand Reputation

Prioritize suppliers with:

- Proven track record: Minimum 5 years of industry-specific experience.

- Transparent testing: Request third-party validation reports for critical metrics like MTBF (Mean Time Between Failures).

Industry Insight: YU-HENG’s open-mouth baggers consistently achieve >5,000 hours MTBF in agricultural applications.

6. Service & Support

- Training: Look for suppliers offering multilingual VR simulations.

- Spare parts: Ensure regional warehouses stock wear components (e.g., sealing jaws, belts).

- Warranty: Opt for ≥3 years of coverage with remote diagnostics.

Cost-Saving Strategies

- Phased implementation: Start with semi-auto models, upgrade automation later.

- Energy efficiency: Regenerative drives cut power use by 15–20%.

- Preventive maintenance: Schedule quarterly inspections to avoid unplanned downtime.

Why Consider Chinese Manufacturers?

- Adaptability: Customize hoppers, feed systems, and controls for niche materials.

- Speed-to-market: Average 4–6 week lead times vs. 12+ weeks for Western suppliers.

- Total cost: Lower lifetime expenses via affordable parts and labor-efficient designs.

Implementation Checklist

- Conduct material trials with potential suppliers.

- Compare 3-year TCO (Total Cost of Ownership), not just upfront price.

- Verify compliance with local safety regulations.