How much is a rice packing machine? That kind is better

When purchasing rice packaging equipment, price and model selection are the two major issues that users are most concerned about. The pricing of devices in the current market has a wide range, which is mainly affected by the level of automation and functional configuration. The price of ordinary semi-automatic models is usually between 3000USD and 7000USD. This kind of equipment requires manual assistance to complete the bagging and sealing process, which is suitable for small processing workshops that have just started. If the medium-sized production enterprises, it is recommended to choose 7000 to 80,000 yuan range of automatic equipment, this type of model can automatically complete the whole process of weighing, bagging and sealing, can process 400-600 bags per hour, the accuracy can also be controlled within a reasonable range. For large grain processing enterprises, high-end models equipped with intelligent control systems are more suitable. Although the price reaches 12000USD to 20000USD, the collaborative operation of double scales and the monitoring function of Internet of things can greatly improve the production capacity, especially for factories that need 24 hours of continuous production.

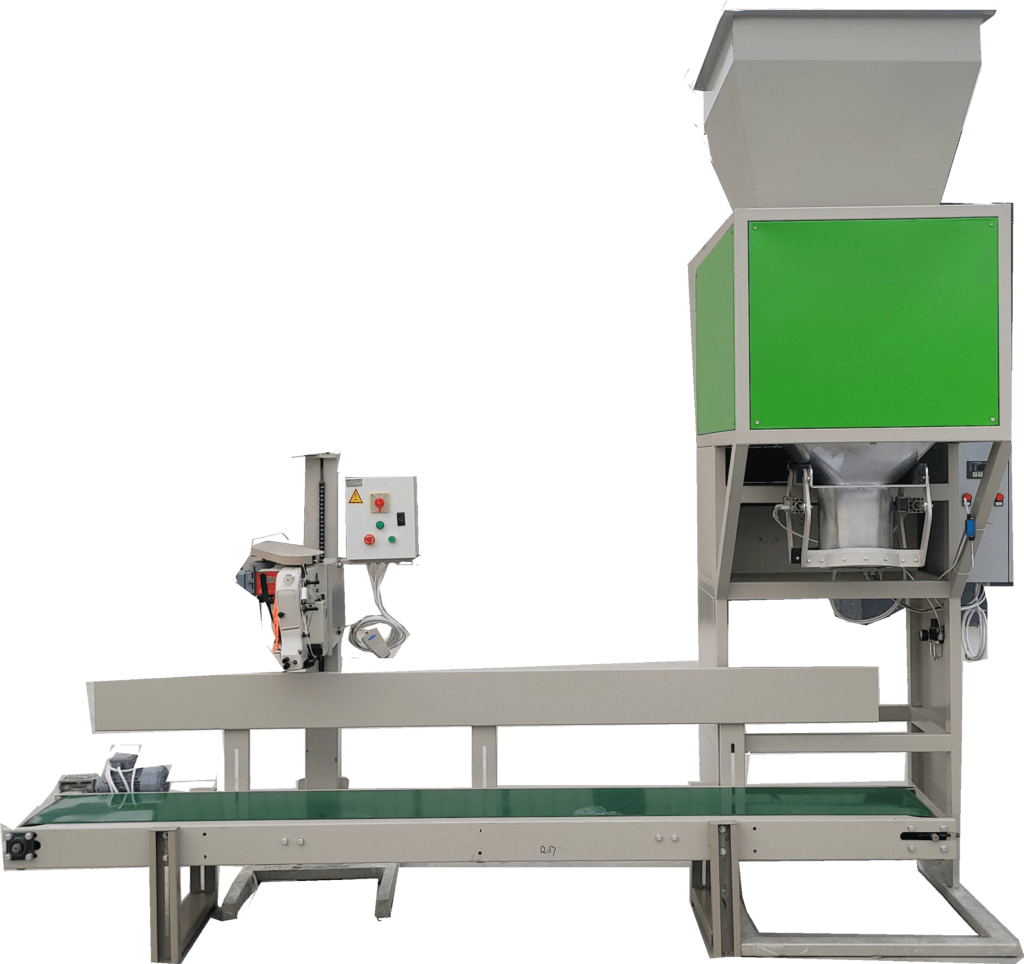

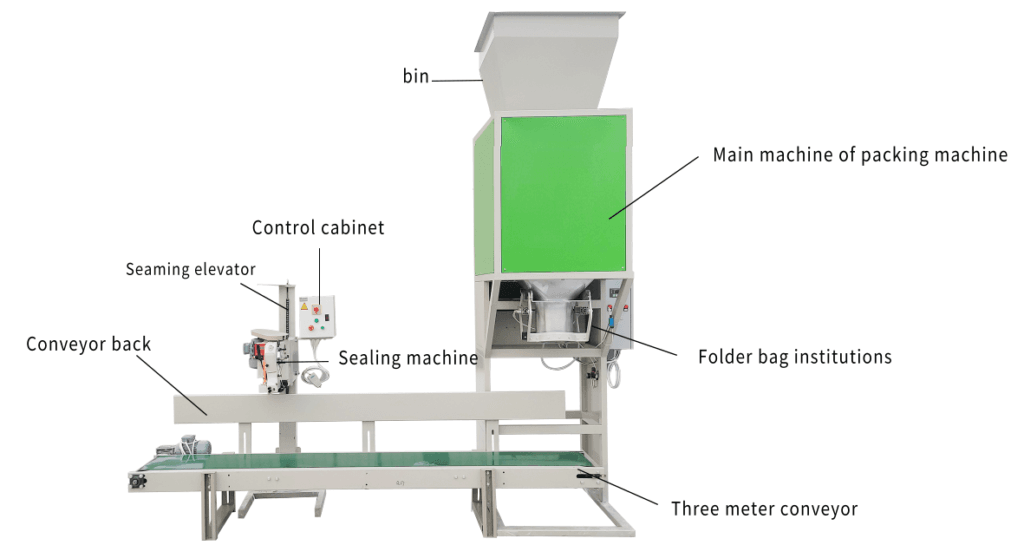

For 30 kg specifications of rice packaging needs, Shanghai Zhuheng brand 15-30 kg quantitative packaging machine is a cost-effective choice. The equipment uses dual-core processing weighing technology, even in the case of continuous operation, each bag error can be stable within 150 grams, equivalent to the weight difference between two or three rice. Stainless steel contact parts are not only durable, but also easy to clean and maintain, which is particularly important for the food processing industry. Actual user feedback shows that in a medium-sized rice factory with a daily output of about 20 tons, the equipment can complete the packaging task by working 8 hours a day, and the qualification rate of sealing is maintained at more than 99%. If there are more types of orders, you can consider the Shanghai Henggang double scale electric packaging machine, its unique parallel operation design can improve the efficiency of 50%, encounter an emergency order with obvious advantages, but also can automatically record the parameters of different packaging specifications, switching varieties without repeated debugging.

There are a few key points to note during the shopping process. First of all, we should check the running state of the equipment on the spot. It is recommended that the manufacturer demonstrate the process of continuous packaging of 100 bags on the spot to observe whether the weighing stability is up to the standard. Secondly, we should carefully check the quality of the core components, such as whether the sensor is a well-known brand, and whether the thickness of the stainless steel plate reaches the industry standard. In terms of cost control, do not be attracted by low prices and ignore hidden costs. Although some manufacturers have cheap equipment, the cost of replacing parts is high in the later stage. It is recommended to give priority to manufacturers that provide free installation and commissioning and one-year warranty of the whole machine. Brands such as Shanghai Yuheng, which have branches in many places, have faster after-sales service response, and faults can usually be solved within 48 hours to avoid delays in production progress.

There are also many practical skills in use. Thickened woven bags are usually used for 30kg packaging, so it is necessary to confirm whether the strength of the bag clamping device of the equipment is sufficient. It is best to bring the actual used packaging bags to the manufacturer for testing. If the workshop environment is humid, you need to inform the manufacturer in advance to install moisture-proof modules to avoid moisture damage to electronic components. Now many intelligent models have reserved the function expansion interface, such as the later can be installed automatic inkjet printer or labeling device, choose and buy may wish to consider this kind of equipment with upgrade space. According to the business data on the Alibaba platform, searching “30kg rice packaging machine” can find nearly 2,000 products. It is recommended to compare the detailed parameters of at least three suppliers, and if possible, arrange a test machine to feel whether the equipment is easy to operate and whether the noise is acceptable.

How much is the rice packing machine?

Price is a problem that users are more concerned about. Generally speaking, the price of a rice packaging machine ranges from 3000 to 14000USD. Due to different models and specifications, different production technical parameters, it is difficult to give users a specific price value.

How much is the rice packing machine? Which is better for packing 30kg of rice? If you want to know more about equipment configuration, on-site trial and other details, please feel free to communicate: