How Much Does a Powder Packaging Machine Cost? The Indispensable Role in Packaging Industry Advancements

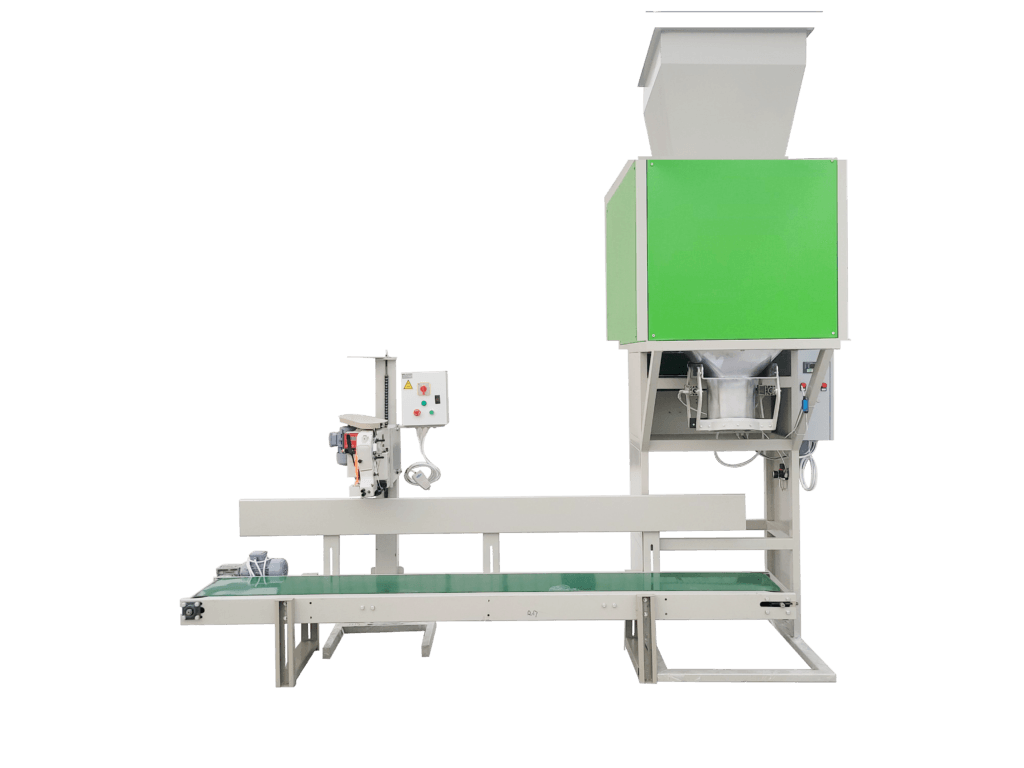

The packaging industry has undergone remarkable transformations, with powder packaging machines emerging as pivotal equipment driving this progress. When evaluating powder packaging machine prices, it’s essential to understand their technological evolution and industry impact. Current market offerings range from $8,000 for basic semi-automatic models to $60,000+ for advanced automated systems, with Chinese manufacturers providing particularly competitive options that deliver 85-90% of Western performance at 40-50% lower cost.

These machines have revolutionized product preservation through vacuum technology innovations, creating oxygen-free environments that extend shelf life by 300-400% for sensitive powders in food, pharmaceuticals, and industrial applications. Modern powder packaging equipment incorporates several breakthrough features:

- Precision dosing systems achieving ±0.5% measurement accuracy

- Gas flushing capabilities for modified atmosphere packaging

- Smart contamination detection with 99.7% impurity recognition rates

- Energy-efficient designs reducing power consumption by 25-30%

The Chinese powder packaging machine sector has made particularly impressive strides, with leading manufacturers now exporting to 120+ countries. Domestic models have closed 80% of the technology gap with international premium brands while maintaining significant price advantages – a typical mid-range Chinese powder packaging machine ($25,000-$35,000) often outperforms similarly priced equipment from other regions in terms of:

- Production speed (50-70 bags/minute)

- Material adaptability (handling powders from 20-200 mesh)

- Maintenance costs (30-40% lower than European equivalents)

Industry projections indicate the global powder packaging machine market will grow at 6.8% CAGR through 2028, with Chinese manufacturers positioned to capture 35-40% of this expansion. This growth stems from continuous improvements in:

- Automation levels (reducing labor requirements by 60-70%)

- Sanitary design (meeting FDA and EU food safety standards)

- Connectivity features (enabling Industry 4.0 integration)

For businesses evaluating powder packaging machine prices, the key consideration should be total cost of ownership rather than just purchase price. Chinese models now offer particularly favorable ROI profiles, typically paying for themselves within 12-18 months through:

✓ 30-50% higher daily output than previous-generation equipment

✓ 20-25% reduction in packaging material waste

✓ 40-60% lower maintenance costs over 5-year periods

The powder packaging revolution shows no signs of slowing, with next-generation innovations like AI-powered quality control and self-adjusting filling systems already entering production. As the industry continues its rapid advancement, these machines will remain indispensable tools for businesses seeking competitive advantage in powder product markets worldwide.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us