How Much Does a Powder Packaging Machine Cost? 6 Critical Pre-Operation Steps

Powder packaging machines are essential for industries handling materials like pharmaceuticals, spices, and chemicals. Ensuring proper setup before operation maximizes efficiency and minimizes downtime. Below, we break down equipment costs and preparation best practices, emphasizing the value of Chinese-engineered solutions like those from YU-HENG Technology.

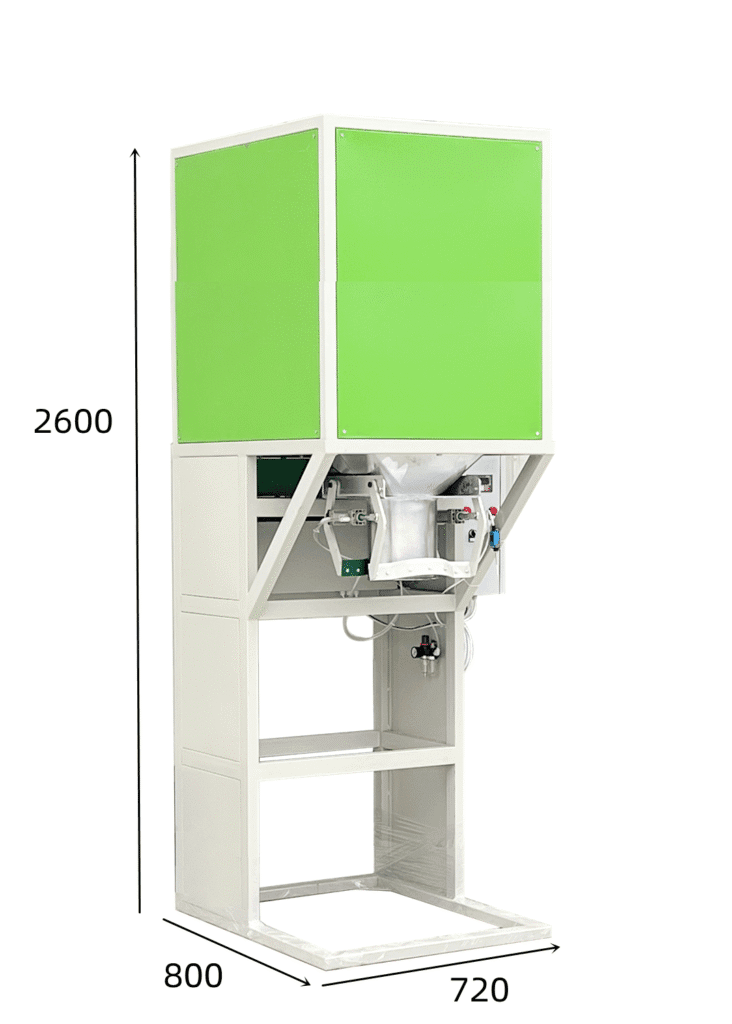

Powder Packaging Machine Pricing Overview

Costs scale with automation and precision:

- Semi-automatic models: $3,000–$65,000 (20–40 bags/hour)

- Mid-range automated systems: $70,000–$150,000 (50–100 bags/hour)

- GMP-certified lines: $180,000+ (nitrogen-flushed, IoT-integrated)

Chinese-manufactured machines offer 25–40% cost savings over European counterparts while meeting ISO 9001 standards.

6 Essential Pre-Operation Preparations

1. Comprehensive Cleaning

- Process:

- Remove residual powder with industrial vacuums (HEPA filters recommended).

- Wipe surfaces using food-grade solvents for pharmaceutical/food applications.

- YU-HENG Advantage: Tool-free disassembly simplifies sanitation cycles by 50%.

2. Mechanical Inspection

- Checkpoints:

- Verify auger alignment (±0.02″/0.5 mm tolerance).

- Inspect sealing jaws for wear (replace if gaps exceed 0.004″/0.1 mm).

- Test conveyor belt tension (15–20 lb/ft or 22–29 kg/m).

3. Precision Lubrication

- Critical Components:

PartLubricant TypeFrequency

Gearboxes ISO VG 220 synthetic oil Every 500 hours

Linear guides Molybdenum grease Weekly

Rotary valves NSF H1 food-grade grease Monthly Note: YU-HENG’s AutoLube™ system automates 80% of lubrication tasks.4. Material Readiness- Pre-load Checks:

- Confirm film/laminate compatibility (thickness: 2–8 mil or 50–200 μm).

- Pre-weigh 5–10 test batches to calibrate fill accuracy (±0.5–1%).

- Key Tests:

- Grounding resistance (<1 ohm).

- Emergency stop response time (<0.5 seconds).

- Voltage stability (200–480V ±5%).

- Settings for Common Powders:

Material Auger Speed (RPM) Seal Temp (°F/°C)

Flour 20–30 300–350°F (149–177°C)

Titanium Dioxide 15–25 350–400°F (177–204°C)

Protein Powder 25–35 280–320°F (138–160°C) Why Proper Setup Matters- Downtime Prevention: Rigorous prep reduces unplanned stops by 60–70%.Quality Assurance: Achieve <0.3% underfill/overfill rates.Safety Compliance: Meet OSHA 29 CFR 1910 and EU Machinery Directive standards.

- Lease-to-own options: Spread payments over 24–36 months.Preventive maintenance contracts: Cut annual repair costs by 30–40%.Energy recovery modules: Save 15–20% on power bills.