How Much Does a Granule Packaging Machine Cost? What Should You Consider When Purchasing One?

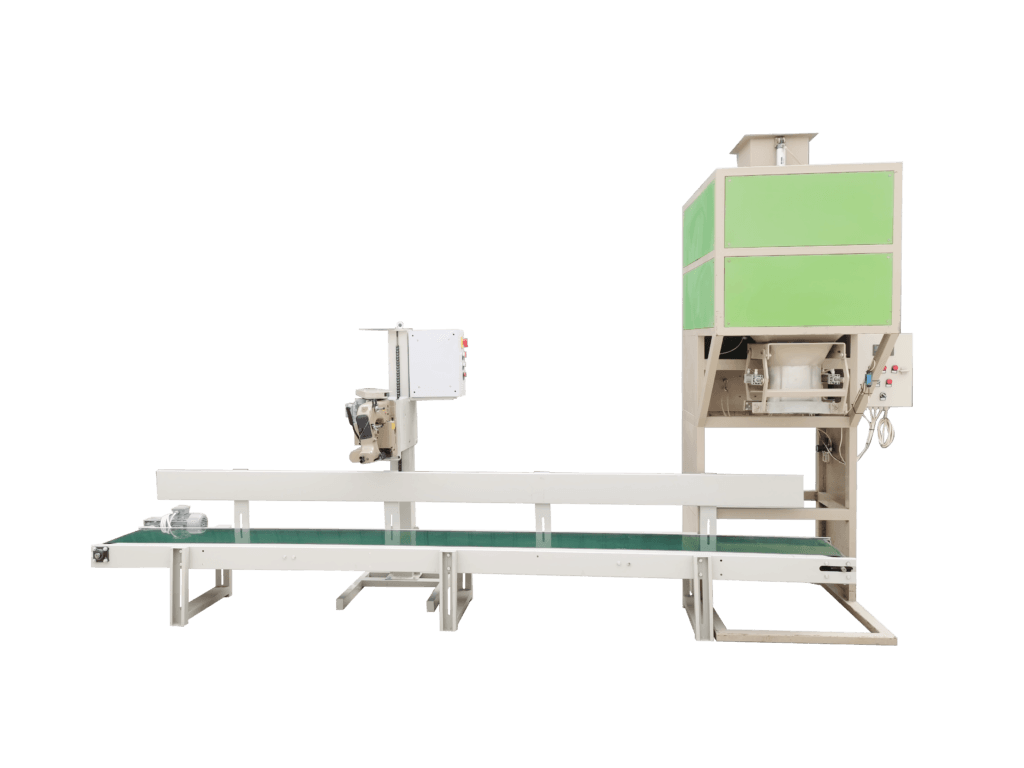

The granule packaging machine is an essential piece of equipment widely used in pharmaceutical, food, and other industries for its efficiency and reliability. However, with so many models available on the market, choosing the right one can be challenging. This guide will help you understand the pricing factors and key considerations when selecting a granule packaging machine.

Granule Packaging Machine Price Range

The cost of a granule packaging machine varies significantly based on its features and capabilities:

- Entry-level models: $5,000–$15,000

- Mid-range semi-automatic machines: $15,000–$30,000

- High-end fully automated systems: $30,000–$80,000+

Key factors affecting price:

✔ Packaging speed (bags per minute)

✔ Precision (multi-head weigher vs. volumetric filling)

✔ Material quality (stainless steel for hygiene-critical industries)

✔ Automation level (manual, semi-auto, or fully automatic)

✔ Additional features (e.g., gas flushing, printing, and labeling systems)

Key Considerations When Purchasing a Granule Packaging Machine

1. Quality vs. Price

- Avoid cheap alternatives: Lower-priced machines often compromise on materials and durability, leading to frequent breakdowns and higher long-term costs.

- Invest wisely: A slightly more expensive machine from a reputable manufacturer will offer better performance and longevity.

2. Manufacturer Reputation

- Choose established brands: Purchase from professional manufacturers with proven track records to ensure quality and reliability.

- Check certifications: Look for machines that meet industry standards (e.g., ISO, CE, or FDA compliance for food/pharma use).

3. After-Sales Support

- Warranty and service: Opt for suppliers offering comprehensive warranties and prompt technical support.

- Spare parts availability: Ensure replacement parts are readily accessible to minimize downtime.

4. Production Requirements

- Match machine specs to your needs: Consider your production volume, packaging speed, and material type (e.g., powders, granules, or pellets).

- Future scalability: Select a machine that can adapt to potential increases in production demand.

5. Hygiene and Safety

- Easy-to-clean design: Machines used in food or pharmaceuticals should have smooth surfaces and minimal crevices to prevent contamination.

- Safety features: Look for emergency stop buttons, protective covers, and compliance with safety regulations.

6. Energy Efficiency

- Lower operational costs: Energy-efficient machines reduce electricity consumption, saving money in the long run.

Why Proper Selection Matters

✅ Higher productivity: A well-chosen machine maximizes output with minimal downtime.

✅ Cost savings: Investing in quality reduces repair and replacement expenses.

✅ Consistent packaging quality: Precise filling and sealing ensure product integrity.

Conclusion

When purchasing a granule packaging machine, prioritize quality, manufacturer reputation, and after-sales support over upfront cost. By carefully evaluating your needs and selecting a reliable machine, you can enhance efficiency and ensure long-term success in your packaging operations.

If you want to know more about the equipment configuration and other details, please feel free to communicate with us