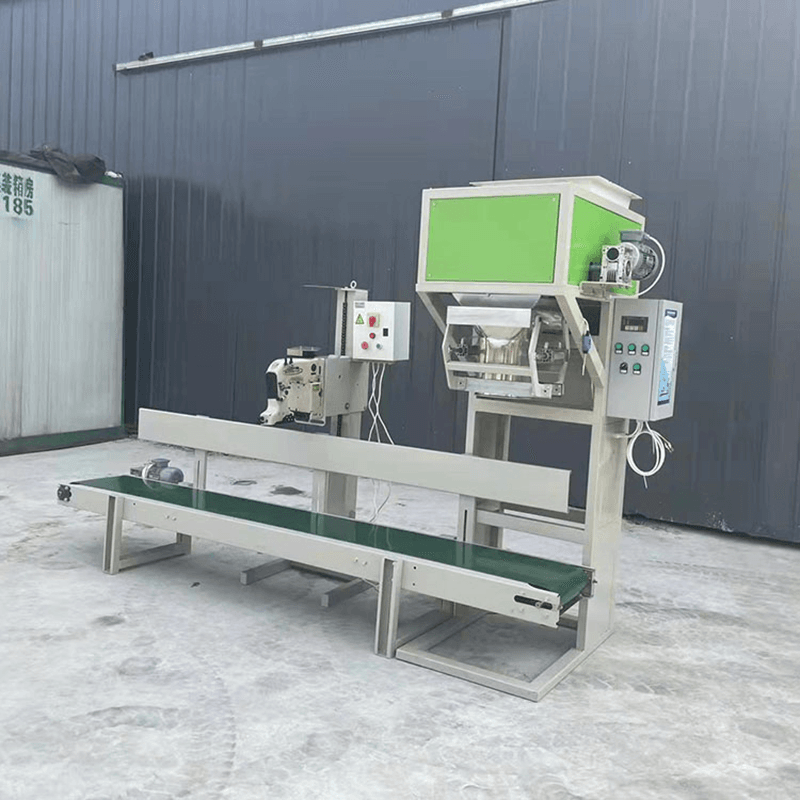

How Much Does a Granule Packaging Machine Cost? What Are the Installation & Debugging Requirements?

Safe and efficient production starts with proper granule packaging machine installation and precise parameter adjustments based on production needs.

At Yuhang Technology Co., Ltd., we provide high-quality granule packaging machines with professional installation guidance, ensuring smooth operation from day one.

How Much Does a Granule Packaging Machine Cost?

The price of a granule packaging machine depends on:

✅ Automation Level – Semi-automatic ($$) vs. fully automatic ($$$)

✅ Production Capacity – Low-speed (cheaper) vs. high-speed (premium)

✅ Material Compatibility – Food-grade, chemical-resistant, or industrial use

✅ Additional Features – Multi-head weighing, vacuum sealing, etc.

A basic semi-automatic granule packaging machine starts around $5,000, while a high-speed fully automatic model can range from $20,000 to $100,000+. For an exact quote, contact Yuhang Technology Co., Ltd.—we offer competitive pricing without compromising quality.

Key Installation Requirements for Granule Packaging Machines

Proper installation ensures long-term performance and minimizes breakdowns. Follow these steps:

1. Machine Placement & Lifting

- Use a crane or forklift to lift the granule packaging machine carefully.

- Assign a supervisor to guide the placement, ensuring smooth, angle-accurate positioning.

- Protect the machine with padding (e.g., foam or packaging paper) to avoid scratches.

2. Alignment & Leveling

After placement, two critical adjustments are needed:

- Boundary Alignment – Ensures the machine fits within the designated workspace.

- Horizontal Leveling – Prevents vibration and uneven wear; use a spirit level for precision.

3. Securing the Machine

- Bolt the machine firmly onto a concrete foundation to prevent movement.

- Tighten all components (hoppers, conveyors, sealing jaws) to avoid operational issues.

4. Initial Adjustments

Before test runs, perform:

- Height Adjustment – Ensures proper material flow.

- Leveling Check – Re-confirms stability.

Debugging & Calibration Steps

After installation, fine-tune the granule packaging machine for optimal performance:

1. Parameter Setting

- Adjust weighing accuracy (for consistent filling).

- Set sealing temperature & time (prevents leaks or burns).

- Calibrate conveyor speed (matches production pace).

2. Test Run & Troubleshooting

- Run empty trials to check motor and sensor functions.

- Gradually introduce granules to test weighing and sealing.

- Monitor for irregularities (e.g., misaligned bags, uneven fills).

3. Operator Training

- Train staff on emergency stops, routine maintenance, and simple fixes.

- Document ideal settings for different granule types (e.g., powders vs. pellets).

Why Choose Yuhang Technology Co., Ltd.?

As a trusted packaging machine manufacturer in China, we offer:

✔ Durable, high-precision granule packaging machines (Made in China reliability).

✔ On-site/remote installation support.

✔ Custom solutions for food, pharmaceuticals, chemicals, and more.

✔ 24/7 technical assistance.

Conclusion

A granule packaging machine’s cost varies by automation and features, while proper installation and debugging ensure efficiency and longevity.

For a high-quality granule packaging machine with expert support, trust Yuhang Technology Co., Ltd.—Contact us today for a tailored solution!

If you want to know more about the equipment configuration and other details, please feel free to communicate with us