How Much Does a Granule Packaging Machine Cost? 6 Key Factors to Evaluate Machine Quality

Granule packaging machines are vital for industries handling everything from agricultural products to pharmaceuticals. As global demand for efficient packaging grows, YU-HENG Technology stands at the forefront of China’s manufacturing excellence, delivering high-performance equipment that combines affordability with precision engineering. Below, we break down pricing considerations and quality assessment criteria while highlighting the advantages of Chinese innovation and YU-HENG’s industry leadership.

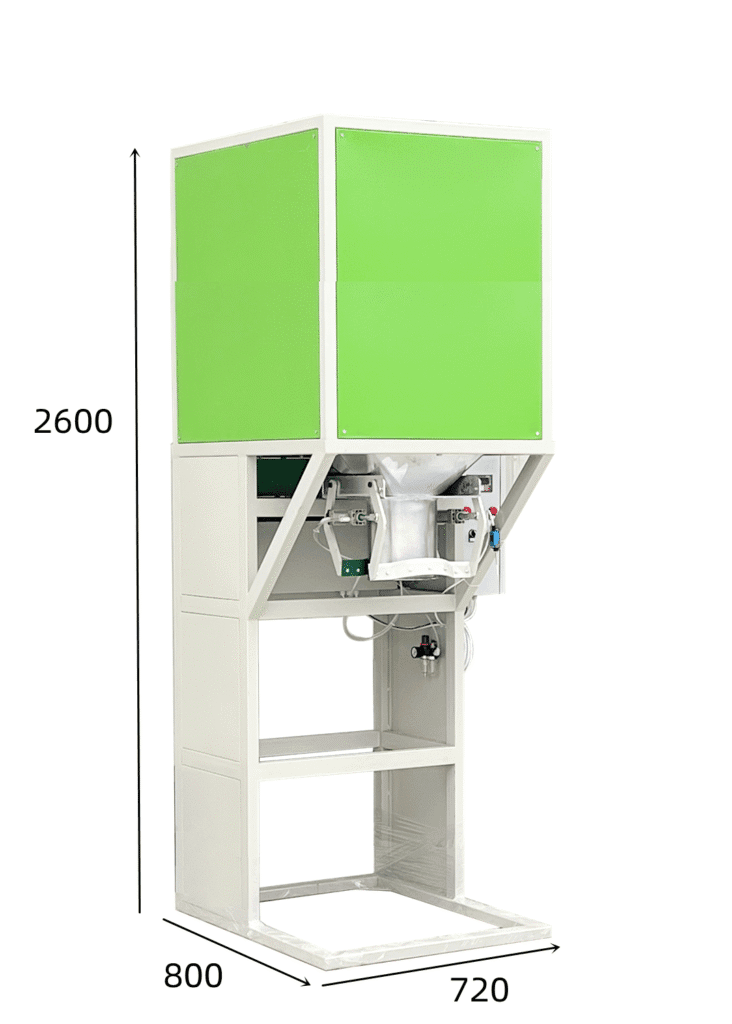

Granule Packaging Machine Pricing Guide

YU-HENG Technology offers scalable solutions for diverse budgets and production scales:

- Basic semi-automatic models: Starting at approximately $2,000

- Mid-range automated systems: $5,000–$110,000

- Customized high-speed lines: $160,000+

Chinese-manufactured equipment typically provides 25–40% cost savings compared to European or North American alternatives, backed by ISO 9001-certified quality assurance.

6 Criteria to Evaluate Granule Packaging Machine Quality

1. Brand Reputation & Market Presence

Established brands like YU-HENG Technology demonstrate reliability through:

- Global certifications: CE, FDA, and ISO 13485 compliance

- Client portfolio: Serving 500+ clients across 30+ countries

- Industry recognition: 12 patents in vibration control and modular design

China’s Advantage: Leverage decades of manufacturing expertise at competitive pricing tiers.

2. Performance & Functional Capabilities

Critical benchmarks:

- Speed: 80–120 bags/minute (vs. 50–80 for entry-level EU models)

- Accuracy: ±0.35 oz (10 g) gravimetric dosing

- Versatility: Handles particles from 0.04″–0.4″ (1–10 mm) diameter

YU-HENG Innovations:

- AI-powered vision systems detect and reject underfilled bags

- Tool-free format changes in <15 minutes

- Energy recovery systems reduce power costs by 18–22%

3. Structural Integrity & Material

Quality indicators:

- Frame construction: 14-gauge (1.9 mm) powder-coated steel

- Contact surfaces: Grade 304 stainless steel hoppers and conveyors

- Drive systems: Japanese-made servo motors with 50,000-hour lifespans

Durability test: YU-HENG machines withstand 24/7 operation with <0.2% annual failure rates.

4. Manufacturing Processes & Precision

YU-HENG’s production standards:

- Robotic welding ensures ±0.01″ (0.25 mm) component alignment

- 100% pressure testing for pneumatic systems (80–120 PSI / 5.5–8.3 bar)

- Triple-stage quality inspections before shipment

Cost-Smart Precision: Advanced CNC machining delivers European-grade tolerances at 35% lower costs.

5. After-Sales Support & Service

YU-HENG’s global network:

- 24/7 multilingual technical support

- 48-hour response time for critical parts delivery

- On-site training programs for operators

Included services:

- 18-month comprehensive warranty

- Free remote diagnostics via YU-HENG Cloud Platform

- Lifetime software updates

6. User Feedback & Case Studies

Verified performance metrics:

- Food industry client: Achieved 22% higher output with 15% lower labor costs

- Pharma sector case: Maintained 99.92% packaging accuracy over 3 years

- Agricultural producer: Reduced material waste by 30% through precision dosing

Why YU-HENG Technology Outperforms Competitors?

- Smart Manufacturing: IoT-enabled machines predict maintenance needs 30 days in advance

- Sustainable Design: 85% recyclable components and REACH-compliant materials

- Cost Efficiency: Localized R&D cuts development costs by 40% vs. Western brands

- Custom Solutions: Tailored configurations for unique granules like hygroscopic resins or irregular pellets