How Much Does a Coal Packaging Machine Cost? Key Factors Behind Its Rapid Market Growth

The rapid advancement of coal packaging machines is driven by several critical factors reshaping the global energy equipment sector. As a leading innovator in this field, YU-HENG Technology combines China’s manufacturing strengths with cutting-edge engineering to deliver cost-effective, high-performance solutions.

1. Enhanced Packaging Efficiency

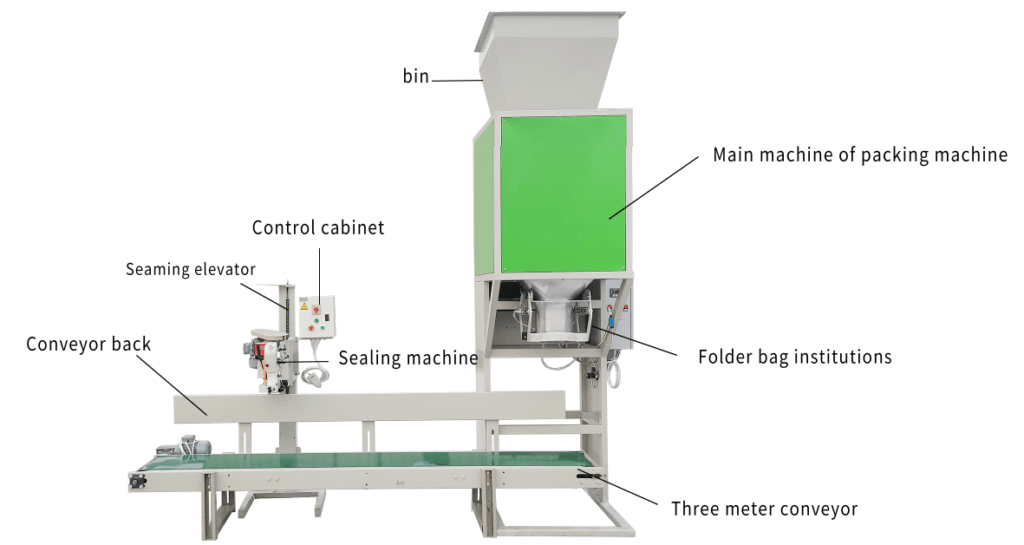

Modern coal packaging machines automate processes that previously required 8-10 manual workers, achieving output rates of 15-25 metric tons per hour (16.5-27.5 US tons). YU-HENG Technology’s systems incorporate:

- AI-powered weighing systems with ±0.5 lb (0.23 kg) accuracy

- Continuous-feed mechanisms reducing downtime by 60-70%

- Modular designs allowing capacity scaling from 500 to 2,000 bags/hour

This efficiency gain translates to 30-50% lower labor costs compared to traditional methods, making Chinese-manufactured equipment particularly attractive for bulk operations.

2. Improved Packaging Quality

YU-HENG Technology’s machines address critical industry challenges:

- Moisture-resistant sealing maintains coal quality during maritime transport (up to 60 days)

- Vibration-dampening systems reduce material loss during rail transit to <0.8%

- Precision portion control ensures consistent 50-2,000 lb (23-907 kg) bag weights

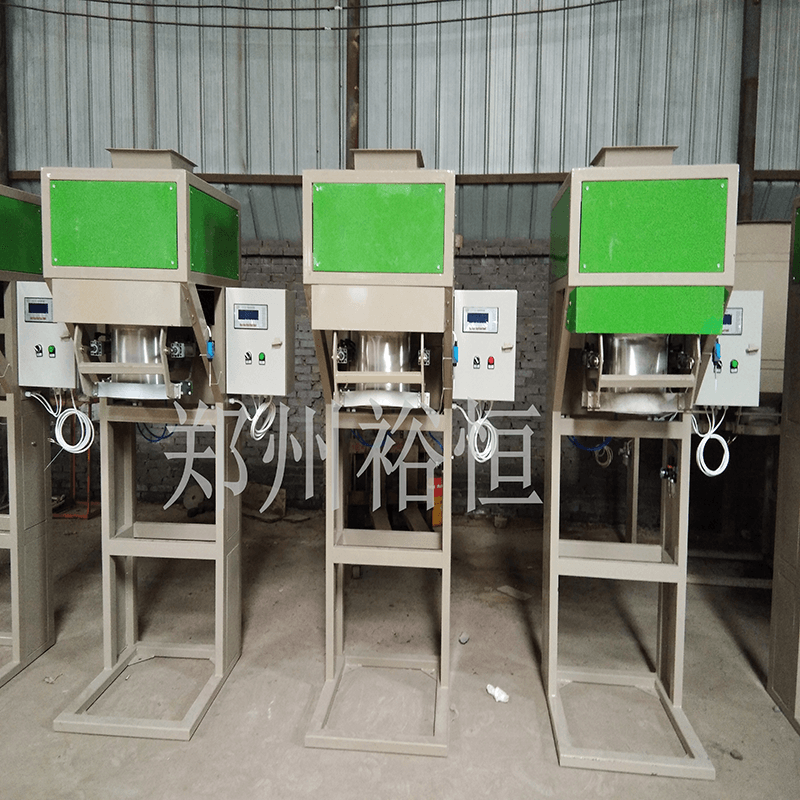

Our ISO 9001-certified production facilities utilize military-grade steel alloys, extending equipment lifespan to 12-15 years with proper maintenance.

3. Competitive Advantage for Enterprises

Adopting advanced packaging technology delivers strategic benefits:

- Brand differentiation: 80% of surveyed clients report improved customer satisfaction

- Sustainability compliance: Meet EPA standards with dust-reduction rates exceeding 95%

- Scalability: Transition from semi-automatic to fully robotic systems without line redesign

YU-HENG’s cloud-connected models provide real-time production analytics, enabling data-driven decision-making for global clients.

4. Innovation & Market Demand Synergy

Three technological breakthroughs fuel industry growth:

- Smart diagnostics: Predictive maintenance reduces repair costs by 40%

- Energy efficiency: Regenerative braking systems cut power consumption by 18-22%

- Customization: Modular components support quick format changes for varied coal grades

Cost Considerations

While pricing varies by configuration, YU-HENG Technology delivers exceptional value:

- Entry-level semi-automatic units: $3,000-$45,000

- Mid-range systems: $75,000-$120,000

- Customized turnkey solutions: $200,000+

Compared to European counterparts, Chinese-manufactured machines typically offer 25-35% cost savings without compromising durability, backed by 3-year comprehensive warranties.