Granule Packaging Machines vs. Powder Packaging Machines: Key Differences and Industry Applications

Granule packaging machines and powder packaging machines are two essential types of industrial equipment designed for distinct materials and operational needs. As global demand for automated packaging solutions grows, companies like YU-HENG Technology leverage China’s advanced manufacturing capabilities to deliver high-performance, cost-effective machines that meet international standards. Below, we break down their differences while highlighting the advantages of Chinese engineering and YU-HENG’s innovative solutions.

1. Material Compatibility

Granule Packaging Machines

These systems excel at handling free-flowing solid particles such as grains, coffee beans, nuts, and plastic pellets. Ideal for agricultural and food industries, they efficiently manage materials with diameters between 0.04″ and 0.4″ (1–10 mm).

Powder Packaging Machines

Designed for fine, cohesive materials like flour, spices, pharmaceutical powders, and cosmetics, these machines address challenges like dust control and precise dosing. They handle particles smaller than 0.02″ (0.5 mm) and often incorporate anti-caking technologies.

YU-HENG Advantage: Our R&D team develops hybrid models capable of switching between granule and powder modes, reducing equipment costs by 25–30% for diversified producers.

2. Filling and Measurement Systems

Granule Packers

- Use gravimetric weighing (±0.35 oz/10 g accuracy) or volumetric counting.

- Achieve speeds of 80–120 bags per minute for standard materials.

- Feature vibratory feeders and bucket elevators for consistent material flow.

Powder Packers

- Rely on auger dosing systems (±0.17 oz/5 g precision) with anti-static components.

- Operate at 50–90 bags per minute, depending on powder density.

- Integrate vacuum-assisted filling to reduce airborne dust by up to 95%.

China’s Manufacturing Edge: YU-HENG’s patented SmartFill™ technology auto-adjusts to material variations, ensuring 99%+ accuracy across both machine types at a fraction of Western costs.

3. Packaging Formats and Adaptability

Granule-Focused Designs

- Support gusseted, block-bottom, and stand-up pouches.

- Handle packaging materials up to 12 mil (0.3 mm) thick.

- Include checkweighers and X-ray contaminant detection for quality control.

Powder-Specific Solutions

- Utilize quad-seal designs to prevent leaks in transit.

- Offer nitrogen-flushing options to extend shelf life by 30–40%.

- Comply with ISO Class 8 cleanroom standards for sensitive industries.

YU-HENG Flexibility: Modular designs allow format changes in under 15 minutes, enabling clients to adapt quickly to market trends without additional capital expenditure.

4. Structural Design and Safety Features

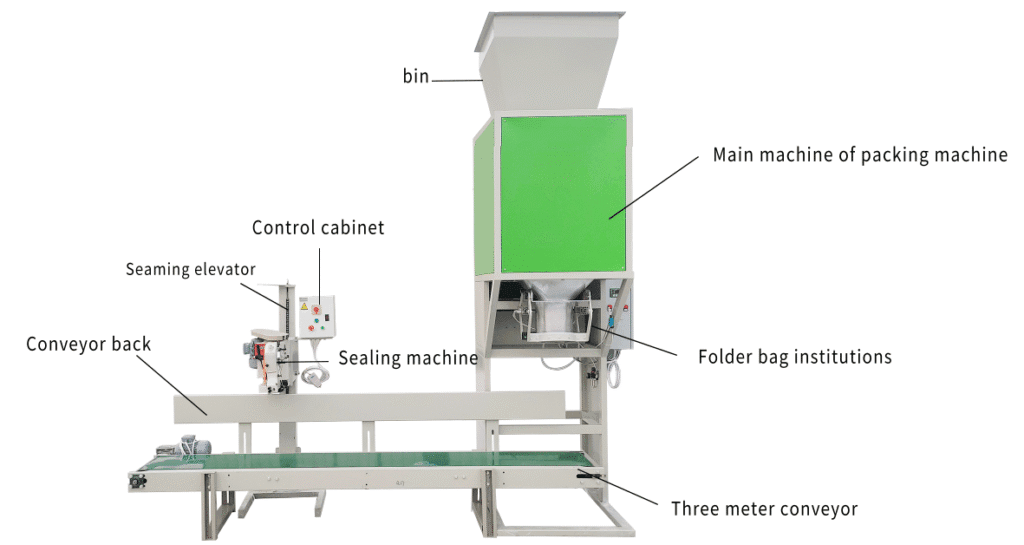

Granule Machine Components

- Constructed with Grade 304 stainless steel vibratory trays.

- Equipped with servo-driven multi-head weighers.

- Include 10″–24″ (25–61 cm) conveyor belts for seamless integration.

Powder Machine Engineering

- Built with airtight Grade 316L stainless steel chambers.

- Feature ATEX-certified explosion-proof motors.

- Incorporate CIP (Clean-in-Place) systems for hygienic industries.

Safety and Compliance: All YU-HENG powder machines meet OSHA and EU ATEX directives, while Chinese production methods keep safety upgrades 20–35% more affordable than European counterparts.

5. Cost Efficiency and ROI

Pricing Comparison

| Machine Type | YU-HENG Price Range | European Equivalent |

|---|---|---|

| Granule Packers | $2,000–$65,000 | +35–50% |

| Powder Packers | $2,000–$120,000 | +40–60% |

Operational Savings:

- Energy recovery systems cut power costs by $2,500–$3,5000 annually.

- Localized spare parts networks reduce downtime by 60–70%.

- 3-year comprehensive warranty with remote diagnostics.

Why YU-HENG Technology?

- Precision Manufacturing: ISO 9001-certified factories with robotic assembly lines ensure consistent quality.

- Global Certifications: CE, FDA, and ECOCERT compliance for hassle-free international shipments.

- Sustainable Practices: 90%+ recyclable components and energy-efficient drives.

- Smart Technology: IoT-enabled performance tracking via YU-HENG Cloud Platform.