Granule Packaging Machine Price Guide & Essential Anti-Corrosion Protection Methods

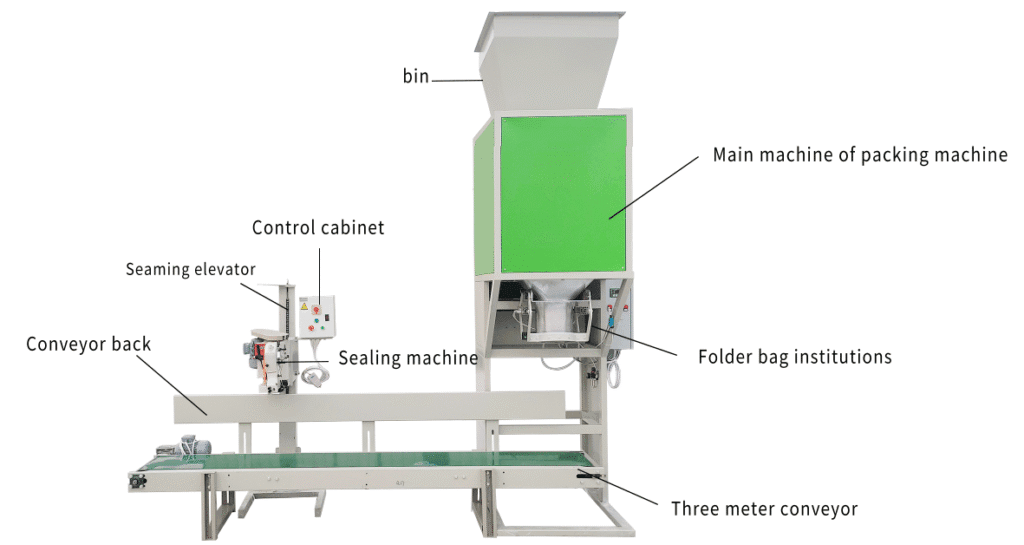

Granule packaging machines are essential equipment for processing rice, seeds, plastic pellets and similar materials across multiple industries. As a leading Chinese manufacturer with 15 years of experience, Yuheng Technology Co., Ltd specializes in producing reliable granule packaging solutions that combine precision engineering with durable construction for long-term performance in various operating environments.

Understanding Granule Packaging Machine Costs

The investment required for a granule packaging system varies significantly depending on production needs and features. Basic semi-automatic models typically range from $3,000 to $45,000, offering capacities of 20-40 bags per minute with standard weighing accuracy. These entry-level machines are ideal for small businesses or operations with limited production requirements. Mid-range automatic systems priced between $45,000 and $110,000 provide increased speeds of 40-80 bags per minute along with improved accuracy and basic dust protection features, making them suitable for medium-sized processing facilities. For large-scale industrial operations, high-end automated lines costing $110,000 to $260,000+ deliver maximum productivity with capacities exceeding 80 bags per minute, pharmaceutical-grade precision, and advanced construction materials designed for continuous operation.

Yuheng Technology stands out in the global market by offering competitively priced machines that maintain international quality standards. Our Chinese manufacturing base allows us to provide cost-effective solutions without compromising on performance or durability, making our granule packaging equipment particularly attractive to international buyers seeking reliable machinery at reasonable prices.

Comprehensive Anti-Corrosion Protection Strategies

Proper corrosion protection is crucial for maintaining granule packaging equipment and ensuring long-term reliability. Regular cleaning forms the foundation of any effective maintenance program. Operators should establish a thorough cleaning protocol that includes daily wipe-downs of all surfaces using approved cleaning solutions, weekly deep cleaning of product contact areas, and monthly disinfection for food-grade applications. Yuheng machines are designed with smooth surfaces and minimal crevices to facilitate easier cleaning and reduce potential corrosion points.

Moisture control represents another critical aspect of corrosion prevention. Since excessive humidity can accelerate equipment deterioration, facilities should maintain workshop humidity below 60% RH whenever possible. Practical solutions include installing dehumidifiers near packaging equipment, using moisture-absorbing materials in control panels, and ensuring proper ventilation throughout the production area. Yuheng packaging systems come standard with protective coatings that provide an additional barrier against moisture-related damage.

The selection of appropriate construction materials significantly impacts a machine’s resistance to corrosion. Yuheng Technology utilizes high-quality stainless steel (304 or 316 grade) for critical components, along with powder-coated exteriors for enhanced protection. For operations in particularly challenging environments, such as coastal areas with salty air, we offer specialized anti-corrosion treatments and marine-grade protection options to extend equipment lifespan.

Implementing a structured preventive maintenance program helps identify and address potential corrosion issues before they become serious problems. This should include monthly lubrication of moving parts, quarterly inspection of electrical components, and annual replacement of wear-prone parts. Yuheng provides detailed maintenance schedules with all our packaging machines to help customers establish effective maintenance routines. Our technical support team is also available to assist with maintenance planning and troubleshooting.

Advanced filtration systems play an important role in protecting sensitive machine components from corrosive contaminants. Yuheng machines feature dual-stage air filtration for control systems, effective dust collection at filling points, and protective covers for vulnerable components. For operations requiring the highest cleanliness standards, we offer optional HEPA filtration systems suitable for cleanroom environments.

Proper storage procedures are equally important for equipment that experiences periodic downtime. Best practices include using climate-controlled storage for spare parts, employing machine covers during extended periods of inactivity, placing desiccant packs in electrical enclosures, and regularly rotating backup equipment to prevent stagnation-related issues. Yuheng provides comprehensive storage guidelines with all our packaging systems to help customers maintain their equipment in optimal condition.

Yuheng Technology’s Advantages in Corrosion Protection

Our extensive experience in manufacturing packaging equipment for global markets has allowed us to develop specialized solutions for corrosion prevention. All Yuheng granule packaging machines feature food-safe stainless steel construction as standard, with optional marine-grade protection packages available for challenging environments. The modular design of our equipment simplifies part replacement when necessary, while our worldwide technical support network ensures customers can access assistance whenever needed.

Practical Implementation Guidelines

To maximize the effectiveness of corrosion protection measures, operators should establish clear implementation routines. Daily operations should include basic cleaning and visual inspections for moisture accumulation or coating damage. Weekly maintenance should focus on lubricating moving parts and checking filter conditions, while monthly inspections should verify electrical component integrity and assess overall machine condition. Yuheng’s customer support team can help develop customized maintenance schedules tailored to specific operating conditions and production requirements.

Conclusion: Protecting Your Investment

Implementing proper corrosion protection measures for granule packaging equipment delivers significant long-term benefits, including extended equipment lifespan, reduced unexpected downtime, maintained product quality, and lower maintenance costs. Yuheng Technology offers durable packaging solutions with built-in corrosion resistance, customizable protection options, and complete after-sales support to help customers get the most from their investment. Our combination of Chinese manufacturing efficiency and international quality standards makes us an ideal partner for businesses worldwide seeking reliable granule packaging solutions.

For operations requiring robust, long-lasting packaging equipment, Yuheng Technology provides machines designed to withstand challenging conditions while maintaining consistent performance. Contact our engineering team today to discuss your specific requirements and learn how our granule packaging solutions can meet your production needs while offering superior corrosion protection.