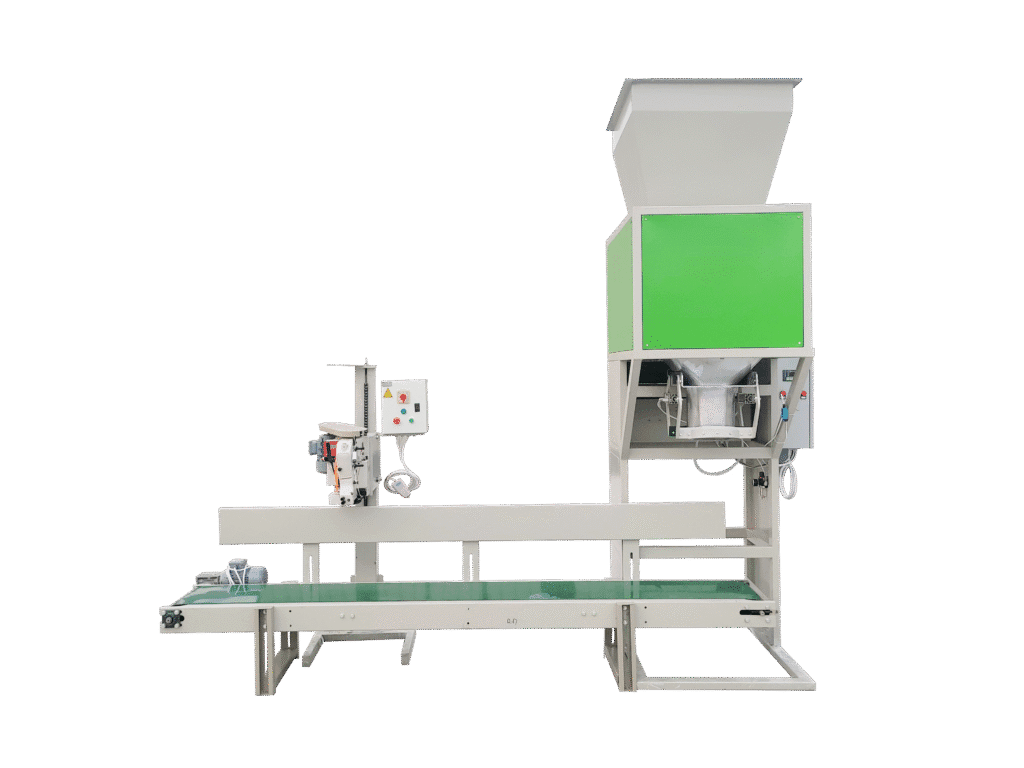

Granular Packaging Machine Pricing & Industry Standards: What You Need to Know

As demand for precision packaging grows across industries like food, pharmaceuticals, and chemicals, granular packaging machines have become essential for modern production lines. Two critical questions dominate buyer discussions: What factors influence granular packaging machine prices? and How are industry standards developed to ensure quality? Yuhang Technology Co., Ltd. (裕恒科技有限公司), a leading Chinese manufacturer, addresses both concerns by delivering competitively priced equipment that aligns with global regulatory frameworks. Below, we analyze pricing variables and unpack the key pillars shaping industry standards.

Factors Affecting Granular Packaging Machine Costs

While prices vary widely ($2,000–$250,000), key determinants include:

- Automation Level: Semi-automatic models suit small-scale operations, while AI-integrated systems cater to high-volume facilities.

- Material Quality: Stainless steel or corrosion-resistant alloys increase durability but add 15–30% to costs.

- Customization: Adjustments like multi-material hoppers or IoT-enabled diagnostics incur additional fees.

Yuhang Tech balances these variables through China’s efficient manufacturing ecosystem, offering modular machines that scale with client needs. For instance, a Nigerian agro-processing firm reduced upfront costs by 22% using our configurable filler-sealer combo.

4 Foundations of Granular Packaging Machine Industry Standards

1. Compliance with National Regulations

Industry standards prioritize adherence to safety, environmental, and quality laws. In China, the GB/T 19001 quality management system mandates rigorous testing for electrical safety and noise control (≤75 dB). Yuhang Tech’s machines exceed these benchmarks, incorporating emergency stop mechanisms and energy-efficient motors to align with EU and North American regulations. This dual compliance ensures seamless market access for global clients.

2. Collaboration with Industry Associations

Organizations like the China Packaging Federation (CPF) and European Packaging Machinery Association (EPMA) shape standards through collective expertise. Yuhang Tech actively participates in CPF working groups, contributing insights on hygienic design for pharmaceutical packaging. Such collaboration ensures our machines meet evolving demands, such as 2023’s revised guidelines for dust-proofing in chemical-grade equipment.

3. Alignment with International Certifications

Global standards like ISO 9001 (quality management) and ISO 14001 (environmental compliance) provide universal benchmarks. Yuhang Tech’s facilities hold both certifications, employing standardized protocols for material sourcing and waste reduction. A recent partnership with a Chilean fertilizer producer highlighted this advantage—their new ISO-compliant machine cut packaging errors by 18% while reducing lubricant waste.

4. Integration of Technical Best Practices

Standards evolve through R&D breakthroughs and field-tested solutions. For example, Yuhang Tech’s anti-static filling systems emerged from collaborations with Indonesian spice processors struggling with granular clumping. By documenting such innovations in technical whitepapers, we help shape industry-wide best practices for moisture control and precision weighing.

Yuhang Tech: Bridging Affordability and Compliance

As a Chinese manufacturer, Yuhang Technology Co., Ltd. leverages localized supply chains and scalable production to keep costs competitive without compromising standards. Our granular packaging machines feature:

- Adaptive Designs: Modify nozzle sizes or conveyor speeds to handle diverse materials like grains, powders, or pellets.

- Proactive Maintenance: IoT sensors alert operators to lubrication needs or part wear, preventing 80% of unplanned downtime.

- Eco-Conscious Engineering: Reduced energy consumption (15–25% lower than industry averages) supports sustainability goals.

A Thai pharmaceutical client reported a 30% faster ROI after switching to our machines, citing reduced compliance costs and higher output consistency.

Why Standards Matter for Your Bottom Line

Adhering to industry standards isn’t just about compliance—it’s a strategic investment. Certified equipment minimizes legal risks, accelerates cross-border sales, and extends machinery lifespan. Yuhang Tech simplifies this process by pre-certifying machines for key markets and providing documentation for local audits.

Partner with China’s Packaging Innovators

Understanding granular packaging machine prices and standards is easier with a transparent supplier. Contact Yuhang Technology Co., Ltd. today to explore solutions that combine Chinese manufacturing efficiency with globally recognized quality—ensuring your operations stay agile, compliant, and cost-effective.