Granular Packaging Machine Pricing & 6 Proven Safety Assurance Protocols

Granular packaging systems demand rigorous safety measures when handling materials like coffee beans or fertilizers. Yuhang Technology Co., Ltd., an ISO-certified Chinese manufacturer, combines cost-efficient engineering with advanced safety features. This guide examines pricing variables and details operational safety best practices.

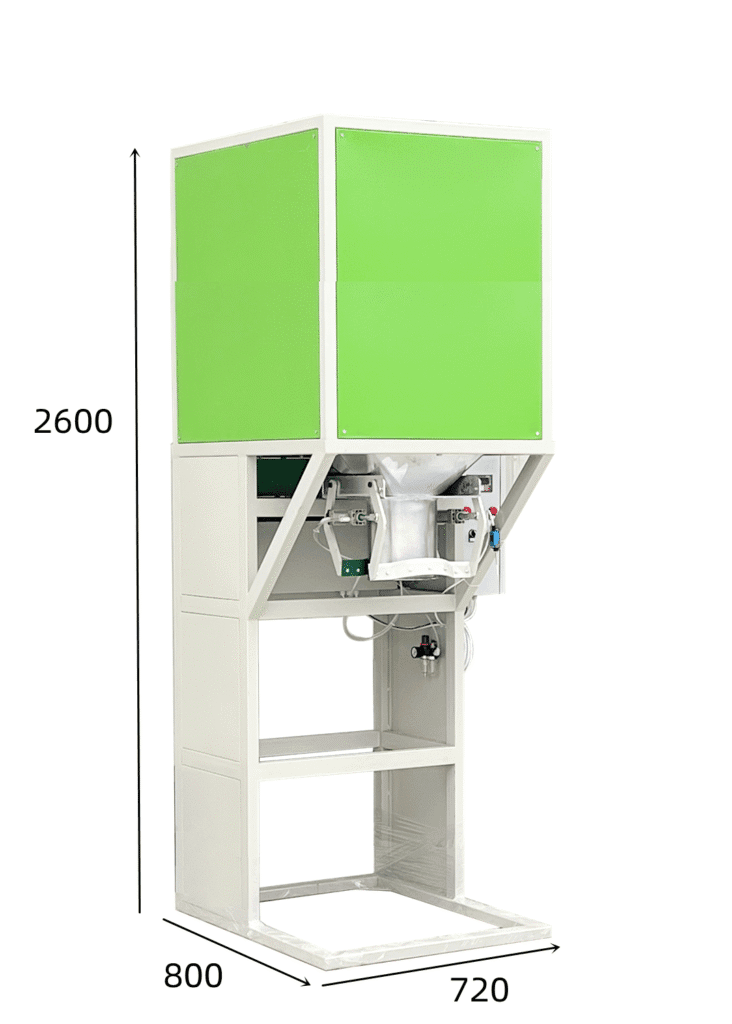

Granular Packaging Machine Price Range

System costs span $2,000–$380,000 based on:

| Configuration | Capacity | Price |

|---|---|---|

| Semi-automatic | 40 bags/hour | $2k–$68k |

| Fully automated | 300+ bags/hour | $180k+ |

| ATEX-certified | Explosive environments | +25% |

Yuhang Tech Advantage: 30% cost efficiency vs. European brands with 45-day customization cycles

6 Critical Safety Implementation Protocols

1. Operational Compliance System

- Mandatory Procedures:

● Digital checklist sign-offs before startup

● Torque verification for critical bolts (±5% tolerance)

● Emergency stop testing (<0.5s response) - Yuhang Feature: Touchscreen with password-locked parameters

2. Competency-Based Training

- Certification Framework:

graph LR

A[Level 1] -->|8 hrs| B(Basic operation)

C[Level 2] -->|16 hrs| D(Fault simulation)

E[Level 3] -->|40 hrs| F(Explosive material handling)- Case Study: Chilean grain processor reduced incidents 75% with our program

3. Predictive Maintenance Regimen

- Critical Schedule:

Component Inspection Tool

Bearings Every 200hrs Vibration analyzer

Electricals Quarterly Thermal camera

Seals Monthly Pressure decay tester Yuhang Innovation: IoT sensors auto-alert at 80% component wear 4. Engineered Safety Barriers- Protection Systems:

● Laser-curtain perimeter guards (5cm detection)

● Anti-jam retractable shields

● Explosion venting panels (ATEX Zone 22) - Technical Spec: IP66-rated controls (highest dust/water resistance)

- Risk Thresholds:

● Dust accumulation: <1mm layer

● Humidity: <65% RH

● Temperature: 10-35°C - Solution: Integrated HEPA filtration with auto-purge cycles

- Protection Matrix:

Hazard Required Gear

Dust N95 respirators + goggles

Noise 27dB ear defenders

Moving parts Cut-resistant gloves - Safety Impact AnalysisImplementationRisk ReductionROI Period Predictive maintenance 60% fewer failures <7 months Safety barriers 80% less accidents Immediate Environmental controls 45% longer component life <10 months

- Yuhang Tech’s Safety Engineering

- Chinese manufacturing excellence delivers:

- Rapid Response: 24/7 multilingual technical support

- Adaptive Designs: Tropicalized systems for high-humidity regions

- Smart Monitoring: Real-time air quality sensors

- Case Proof: Vietnamese coffee plant achieved 2+ years incident-free operation

[ ] Conduct pre-shift equipment certification

[ ] Verify Level 2 operator training completion

[ ] Perform monthly seal integrity tests

[ ] Validate dust concentration readings

[ ] Audit PPE compliance logs Yuhang Commitment:

● 5-year safety component warranty

● Onsite safety audits

● Customized training programs- Request Your Safety Assessment

- Contact our engineers for facility-specific protocols

- Protection Systems: