Granular Packaging Equipment Costs & Key Signs of Bearing Lubrication Issues

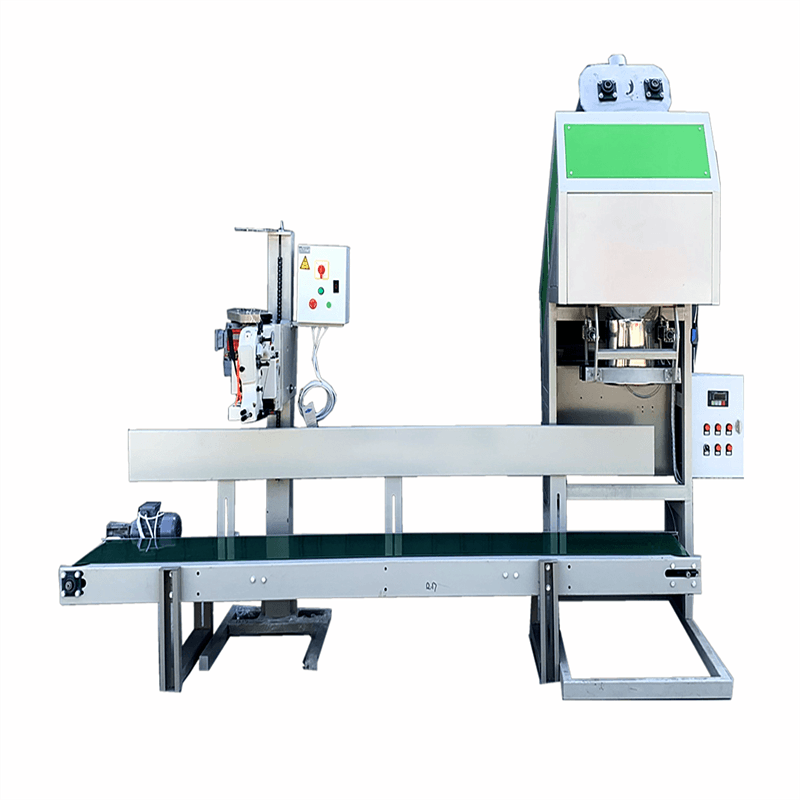

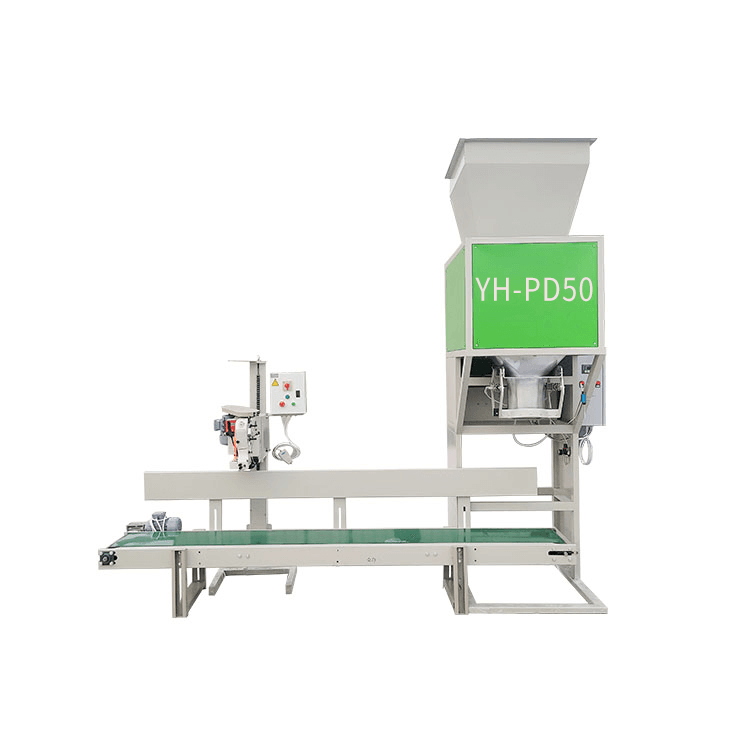

As industries increasingly rely on automated solutions for efficient production, granular packaging equipment has become indispensable for sectors like agriculture, pharmaceuticals, and food processing. However, two critical concerns dominate buyer decisions: understanding pricing factors and recognizing early signs of mechanical wear, such as bearing lubrication failures. Yuhang Technology Co., Ltd., a trusted Chinese manufacturer of packaging machinery, addresses these challenges by delivering cost-effective, low-maintenance systems tailored to global operational needs. Below, we break down pricing variables and outline how to identify and resolve bearing lubrication issues.

What Influences Granular Packaging Equipment Prices?

- Automation Level

Semi-automatic machines are budget-friendly (starting at $15,000), while fully automated lines with AI-driven controls can exceed $100,000. Yuhang Tech offers scalable solutions, allowing clients to invest in modular systems that grow with their production demands. - Material & Build Quality

Stainless steel components or food-grade coatings increase durability but also costs. By leveraging China’s robust supply chain, Yuhang Tech balances premium materials with competitive pricing—a key advantage for businesses seeking long-term value. - Customization Needs

Adjustments like variable-speed fillers or specialized hopper designs add 10–25% to base prices. Our engineers work closely with clients to prioritize high-impact modifications, ensuring cost efficiency. - After-Sales Support

Suppliers offering extended warranties or on-site maintenance typically charge 5–15% more upfront. Yuhang Tech’s global service network minimizes this burden through remote diagnostics and affordable annual service plans.

5 Warning Signs of Low Bearing Lubrication in Packaging Machinery

- Abnormal Noises During Operation

Grinding, squeaking, or rattling sounds often indicate insufficient lubrication. For instance, a Yuhang Tech client in Thailand reported intermittent “clicking” noises from their granular filler—a issue resolved by replenishing high-temperature grease in the drive shaft bearings. - Increased Operational Resistance

Motors consuming 10–20% more power or belts slipping frequently may signal excessive friction. Regular lubrication reduces energy waste and prevents premature motor burnout. - Rising Bearing Temperatures

Infrared tests showing temperatures above 160°F (71°C) suggest lubrication failure. Yuhang Tech’s equipment integrates thermal sensors that trigger alerts before overheating damages adjacent components. - Unstable Machine Vibration

Erratic vibrations disrupt weighing accuracy in granular packagers. In a recent case, a Nigerian agro-business eliminated uneven packaging by adopting our auto-lubrication systems, which maintain consistent bearing oil levels. - Accelerated Wear & Corrosion

Visible pitting or rust on bearing surfaces often stems from prolonged dry operation. Our machines feature sealed bearing housings and corrosion-resistant alloys to extend part lifespans in humid climates.

Proactive Maintenance: Yuhang Tech’s Approach to

Addressing lubrication issues early is crucial to avoid costly downtime. Yuhang Technology Co., Ltd. recommends:

- Monthly Inspections: Check grease levels and purge contaminants.

- Smart Lubrication Systems: Upgrade to automatic dispensers ($1,200–$3,500) for precision oiling.

- Staff Training: Teach operators to recognize early warning signs.

As a Chinese manufacturer, we combine rigorous quality control (ISO 9001-certified) with cost-saving innovations. Our granular packaging machines, for example, use centralized lu

Why Partner with Yuhang Tech?

- Budget Flexibility: Machines start at $18,500 with financing options.

- Adaptive Engineering: Modify bearing types or lubrication ports to suit your materials.

- Eco-Conscious Design: Reduced grease waste and energy-efficient motors align with global sustainability goals.

Don’t let bearing failures disrupt your productivity. Contact Yuhang Technology Co., Ltd. today to explore granular packaging solutions that prioritize durability, ease of maintenance, and transparent pricing—all backed by China’s renowned manufacturing efficiency.