Grain Packaging Machine Costs & Essential Post-Use Maintenance Guide

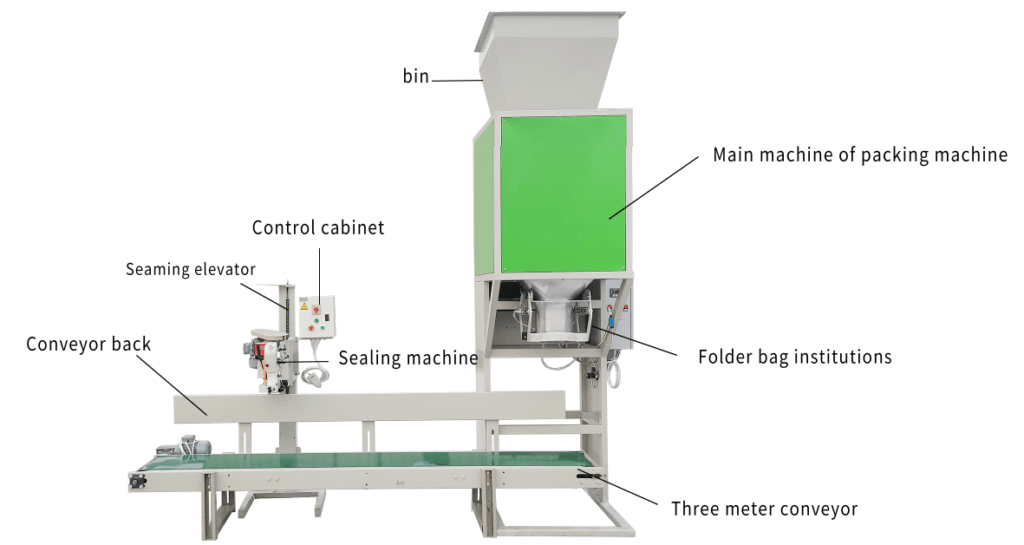

Grain packaging machines are vital for agriculture and food processing industries, ensuring efficient and hygienic packaging of rice, wheat, beans, and other bulk grains. Below, we break down pricing factors and provide actionable maintenance protocols to maximize equipment lifespan and performance.

Grain Packaging Machine Pricing Overview

Costs vary by capacity and automation level:

- Semi-automatic models: $3,000–$60,000 (20–40 bags/hour)

- Mid-range automated: $70,000–$150,000 (50–100 bags/hour)

- High-volume systems: $160,000+ (150+ bags/hour, IoT-integrated)

Chinese manufacturers like YU-HENG Technology offer 25–40% cost savings compared to Western brands while meeting ISO 22000 food safety standards.

6 Critical Post-Use Maintenance Steps

1. Thorough Cleaning & Sanitation

- Process:

- Use food-grade vacuums to remove grain dust from hoppers and conveyors.

- Sanitize sealing jaws with 70% ethanol to prevent microbial growth.

- Clean spillage trays and sensors with compressed air (<30 PSI/2 bar).

- Frequency: After each production shift.

2. Wear-Part Inspection & Replacement

| Component | Inspection Focus | Replacement Threshold |

|---|---|---|

| V-belts | Cracks, fraying | 10% width reduction |

| Silicone gaskets | Deformation, hardness loss | >0.04″ (1 mm) thickness decrease |

| Auger flights | Edge wear, corrosion | >15% material loss |

Pro Tip: Stock spare parts kits to reduce downtime by 50–70%.

3. Precision Lubrication

- Lubrication Schedule:

PartLubricantFrequency

Chain drives NSF H1 food-grade oil Every 8 operating hours

Gearboxes ISO VG 220 synthetic 500 hours

Linear bearings Molybdenum grease Weekly 4. Parameter Optimization- Key Adjustments:

- Weighing accuracy: Recalibrate load cells using 50 lb (22.7 kg) test weights.

- Sealing temperature: Set between 300–350°F (149–177°C) for poly-lined grain bags.

- Vibration intensity: Adjust feeder amplitude to match grain size (e.g., 2–4 mm rice vs. 5–8 mm beans).

- Environmental controls:

- Maintain 40–80°F (4–27°C) storage temperature.

- Humidity <60% RH to prevent corrosion.

- Cover machines with breathable anti-dust sheets.

- Component prep:

- Drain residual grains from hoppers.

- Loosen belt tension to 70% of operating specs.

- Digital tracking:

- Use CMMS (Computerized Maintenance Management Systems) to log:

- Lubrication dates

- Part replacement history

- Calibration records

- Attach QR code tags to machines for