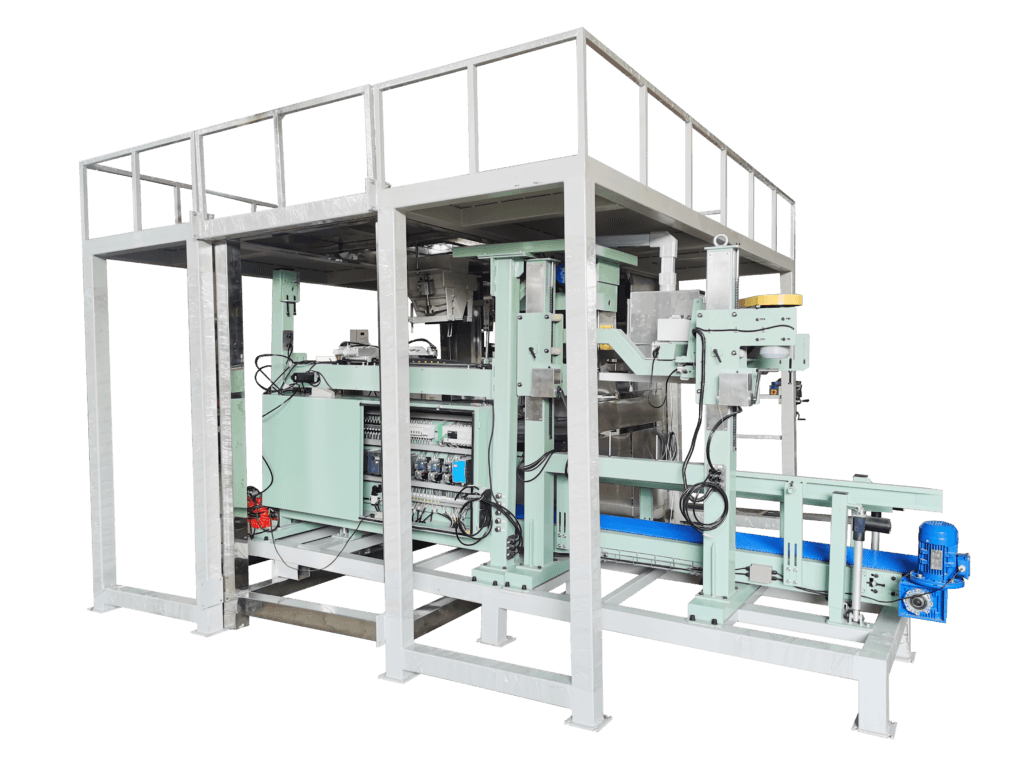

Fully Automatic Powder Packaging Machine Price and Troubleshooting Guide

For manufacturers handling powdered products, two critical questions often arise: What is the price range for fully automatic powder packaging machines? and How to quickly resolve common operational issues? As an experienced Chinese packaging equipment manufacturer, Yuheng Technology Co., Ltd provides this practical guide to help international buyers understand costs and maintenance solutions.

Price Range for Fully Automatic Powder Packaging Machines

- Entry-Level Models ($25,000-$45,000)

- Capacity: 20-40 bags/minute

- Ideal for: Small-scale food, pharmaceutical, or chemical producers

- Features: Basic weighing system, semi-closed design

- Mid-Range Systems ($50,000-$100,000)

- Capacity: 50-120 bags/minute

- Includes: Advanced dust control, touchscreen interface

- Suitable for: Medium-sized powder processing plants

- High-End Production Lines ($110,000-$250,000+)

- Capacity: 150-300 bags/minute

- Technology: Fully enclosed with AI-powered adjustment

- Designed for: Large pharmaceutical or food corporations

Yuheng standard configurations offer:

✔ 316L stainless steel contact surfaces

✔ IP65 protection grade electrical components

✔ 5-year motor warranty

Common Operational Issues and Practical Solutions

1. Dust Control Challenges

Powder materials naturally generate dust during packaging. Yuheng machines address this through:

- Sealed transfer systems with magnetic docking connections

- Dual-stage vacuum recovery capturing 98% of airborne particles

- Built-in air purification maintaining clean operation environment

- Operator protection with optional isolation cabins

Maintenance Tip: Clean dust filters after each shift and inspect sealing strips weekly.

2. Material Flow Consistency

Powder characteristics vary significantly. Our solutions include:

- Adaptive twin-screw feeders automatically adjusting to density changes

- Vibration-assisted hoppers preventing material bridging

- Real-time monitoring sensors detecting flow abnormalities

- PLC-controlled dosing with ±0.5% accuracy

Troubleshooting: For irregular flow, check:

➔ Hopper vibration settings

➔ Screw feeder clearance

➔ Material moisture content

3. Weighing Accuracy Fluctuations

Common causes and fixes:

- Static electricity → Install ionizing bars

- Mechanical vibration → Adjust damper settings

- Environmental factors → Maintain stable temperature/humidity

4. Bag Sealing Quality Issues

Ensure consistent seals by:

- Calibrating temperature monthly

- Replacing sealing jaws annually

- Verifying pressure settings weekly

Why Global Clients Choose Yuheng

- Smart Self-Diagnosis: 90% common issues identifiable via touchscreen

- Quick-Change Design: <15 minutes for complete format adjustment

- Global Support: Multilingual remote assistance available 24/7

- Cost Efficiency: 35% lower lifecycle costs than European brands

If you want to know more about the equipment configuration and other details, please feel free to communicate with us