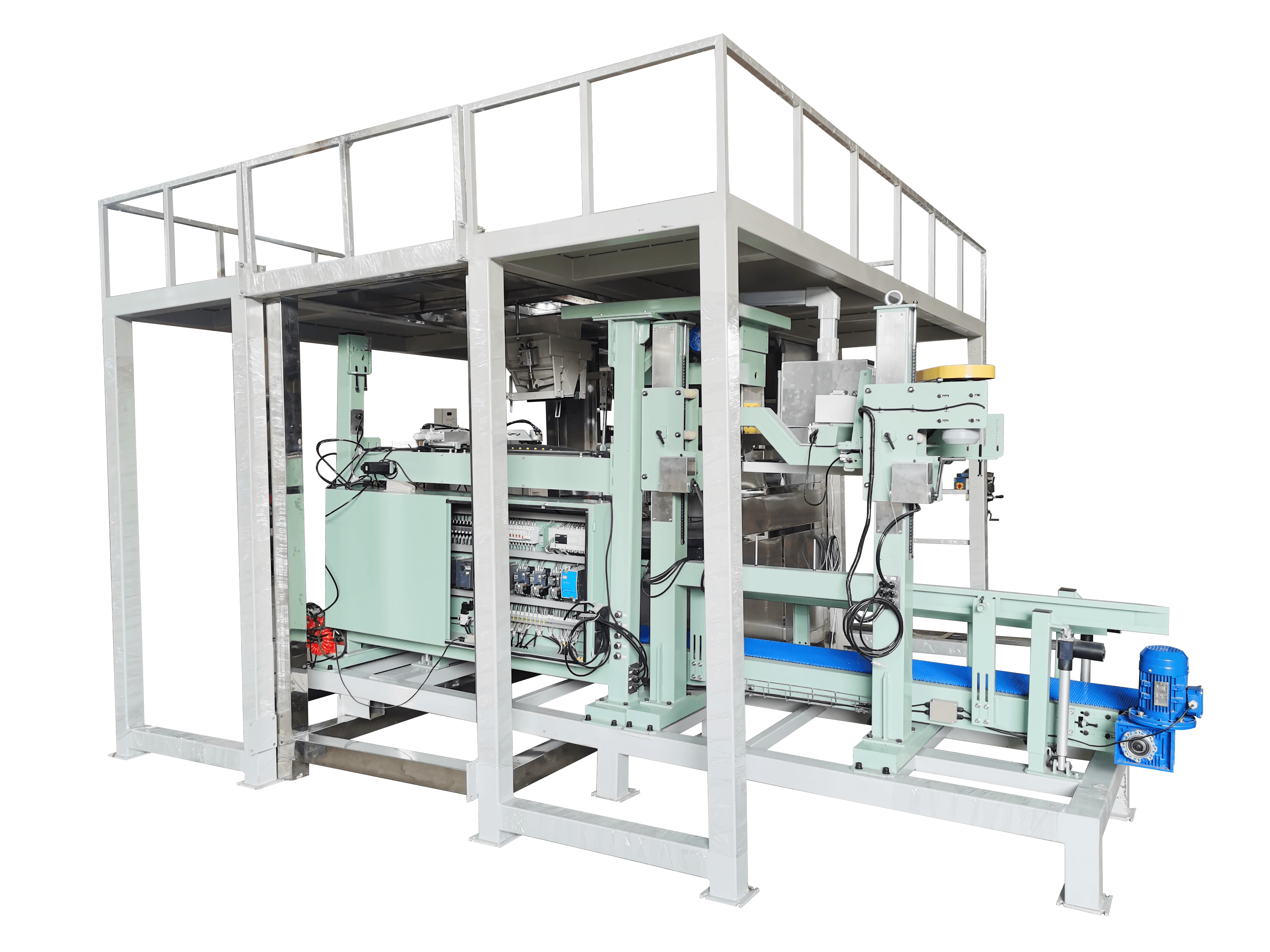

Fully Automatic Packaging Machinery Price & Common Causes of Jamming

Introduction

Jamming issues in fully automatic packaging machinery can arise from various factors. Understanding these causes helps in preventive maintenance and ensures smooth operation. Below are common reasons that may lead to equipment jamming.

Common Causes of Jamming in Fully Automatic Packaging Machinery

- Feeding System Issues

Worn or damaged components in the feeding system, such as conveyor belts or feeding screws, can disrupt material supply and cause jamming. - Electrical System Failures

Malfunctions in motors, controllers, or sensors may lead to operational abnormalities and result in equipment jamming. - Software or Program Errors

Incorrect settings or incompatible software updates can cause operational disruptions and jamming. - Mechanical Component Wear

Long-term operation may cause wear in parts such as transmission belts, gears, or guides, potentially leading to jamming. - Lack of Maintenance

Insufficient regular maintenance can reduce equipment performance, increase failure rates, and contribute to jamming. - Material-Related Problems

Unsuitable material characteristics, such as humidity, viscosity, or particle size, may cause jamming during the packaging process.

To minimize jamming, regular maintenance and operator training are essential. Ensuring proper operation and adherence to guidelines can significantly reduce downtime.

How Much Does Fully Automatic Packaging Machinery Cost?

The price of fully automatic packaging machinery varies based on type, model, brand, and technical specifications. Additionally, fluctuations in raw material costs (e.g., steel prices) may affect pricing.

For accurate and up-to-date quotations, we recommend contacting Yuhang Technology Co., Ltd. directly. Our team provides detailed pricing information tailored to your specific requirements.