Cost Analysis of Fully Automated Packaging Machines: Standard Equipment in Food Industry

Fully automated packaging systems have become essential infrastructure in modern food production, combining efficiency with quality control. As an innovator in intelligent packaging solutions, Yuheng Technology Co., Ltd. provides cost-effective equipment that meets global standards while demonstrating China’s manufacturing capabilities.

Pricing Factors for Automated Packaging Systems

Equipment costs typically range from approximately $2,000 to $450,000, influenced by:

- Production speed requirements

- Material compatibility (liquids/powders/solids)

- Certification levels (FDA, ISO 22000, etc.)

- Smart features integration

Chinese-manufactured systems like Yuheng’s models offer competitive pricing through modular designs, with most clients achieving ROI within 20 months through labor cost reductions and productivity improvements.

Key Advantages in Food Applications

1. Enhanced Production Efficiency

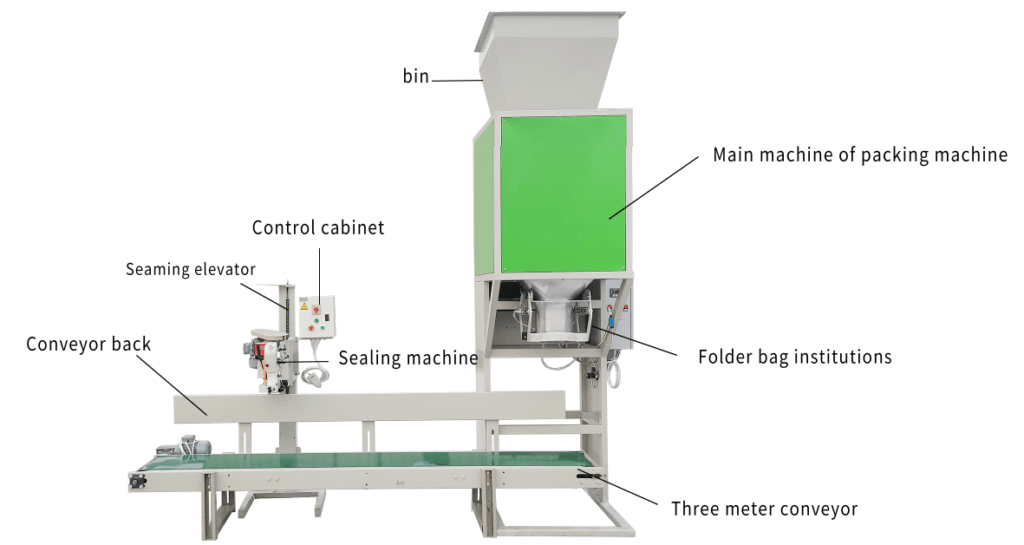

Integrated automated workflows handle conveying, measuring, sealing, and palletizing simultaneously. Yuheng’s systems typically increase output by 3-5 times compared to semi-automatic equipment while reducing energy consumption through advanced motor technologies.

2. Precision Measurement

Advanced dosing systems maintain weight accuracy within tight tolerances, crucial for compliance with packaging regulations. Specialized solutions prevent measurement errors caused by static or moisture absorption in products like seasoning powders.

3. Flexible Format Adaptation

Quick-change mechanisms allow rapid switching between:

- Pouch types (stand-up/vacuum/zipper bags)

- Rigid packaging (boxes/cans/bottles)

- Bulk container filling

4. Labor Optimization

Automated operations reduce direct staffing needs by approximately 60-70%. Yuheng’s intelligent control interfaces enable single-operator management of multiple production lines, significantly decreasing human error rates.

5. Food Safety Assurance

Constructed with food-grade materials and enclosed designs, the equipment minimizes contamination risks. Intelligent sealing systems maintain consistent package integrity, extending shelf life for perishable goods.

Industry Standardization Drivers

- Cost Efficiency: Decreasing equipment prices with localized supply chains

- Regulatory Compliance: Evolving food safety requirements

- Market Demands: E-commerce requiring 99%+ packaging integrity rates

Yuheng Technology continues to refine equipment for regional food characteristics, such as high-oil snacks and fragile baked goods, supporting clients in global market expansion.