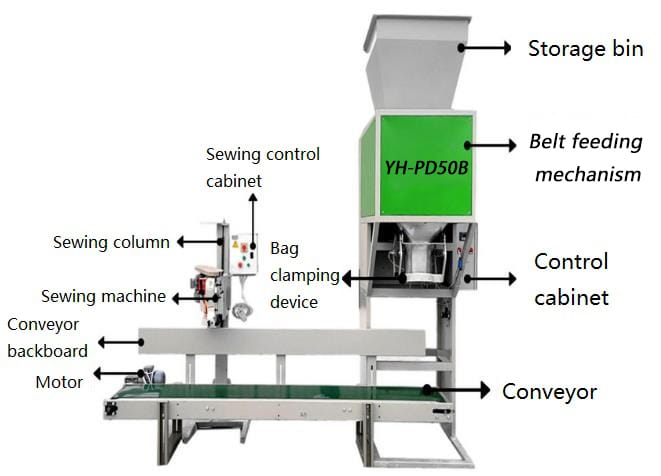

Coal Packaging Machinery: Complete Pricing Analysis and Professional Installation Guidelines

Introduction

Coal packaging systems have become indispensable in modern mining operations and energy production facilities worldwide. As a premier Chinese manufacturer with ISO 9001 certification and 18 years of heavy-industry experience, Yuheng Technology specializes in engineering robust coal packaging solutions that combine durability with precision performance.

Section 1: Coal Packaging Machine Investment Overview

The capital expenditure for industrial-grade coal packaging equipment varies significantly based on operational requirements:

- Equipment Classifications and Capabilities

- Standard semi-automatic models ($35,000-$75,000) provide basic functionality for small-scale operations processing 15-25 tons/hour

- Automated systems ($75,000-$160,000) incorporate advanced dust containment and can handle 25-50 tons/hour

- Custom heavy-duty solutions ($160,000-$350,000+) deliver maximum throughput of 50-100 tons/hour with full automation

- Throughput and Efficiency Metrics

Our field data demonstrates:

- Base models achieve 92-95% operational efficiency

- Automated systems maintain 96-98% efficiency

- Custom solutions can reach 99% efficiency in optimal conditions

- Key Cost Determinants

Additional investment considerations include:

- Abrasion-resistant lining materials (+15-20%)

- Explosion-proof certifications (+25-35%)

- Custom conveyor configurations (+20-30%)

Yuheng Technology Competitive Advantages:

- Vertical manufacturing integration reduces costs by 30-40% compared to European equivalents

- CE and ATEX certified production facilities with annual capacity exceeding 800 units

- Proprietary WearShield™ technology extends component life by 50%

- Optional 5-year comprehensive warranty packages

Section 2: Comprehensive Installation and Commissioning Protocol

1. Site Preparation Specifications

Environmental Requirements:

- Minimum 5-ton/m² floor load capacity

- Operating temperature range: -20°C to 50°C

- Maximum relative humidity: 80% non-condensing

- Ambient dust levels below 5mg/m³

Foundation Engineering:

- 400mm reinforced concrete base with steel rebar

- Vibration isolation mounts with 50mm deflection capacity

- Anchor bolt positioning tolerance within ±2mm

2. Mechanical Installation Process

Phased Implementation:

- Uncrating and Inspection

- Component verification against bill of materials

- Structural integrity assessment

- Surface preparation for assembly

- Precision Alignment

- Laser-guided leveling to 0.1mm/m tolerance

- Epoxy grout application with 72-hour cure period

- Final alignment verification

- System Assembly

- Primary frame installation

- Weighbridge mounting and calibration

- Conveyor system integration

- Dust collection unit positioning

3. Electrical and Control System Commissioning

Wiring Standards:

- Minimum 6mm² copper power cabling

- Shielded signal cables with EMI protection

- Grounding system resistance below 4Ω

Control System Configuration:

- PLC parameter programming

- Weighing threshold settings

- Safety interlock verification

- Material characteristic inputs

4. Performance Validation Testing

Mechanical Systems Check:

- Belt tension measurement (5-8mm deflection)

- Chain lubrication verification (ISO VG 220)

- Gear backlash adjustment (0.1-0.15mm)

Electrical Systems Verification:

- Insulation resistance testing (>1MΩ)

- Phase sequence confirmation

- Emergency circuit functionality

5. Operational Calibration Procedures

Critical Adjustments:

- Precision Weighing System

- Zero point calibration

- Span adjustment

- Vibration compensation

- Dust Management System

- Airflow velocity optimization

- Filter pulse timing configuration

- Extraction balance adjustment

Performance Certification:

- 10-consecutive batch consistency test

- ±1% packaging accuracy requirement

- Automatic compensation system validation

Section 3: Yuheng’s Global Installation Support Network

- Commissioning Service Packages

- Basic Support: Remote guidance with 3D manuals (3 days)

- Standard Package: On-site technician with metrology tools (5 days)

- Premium Solution: Full engineering team with testing equipment (10 days)

- Digital Documentation System

- Interactive 3D operation manuals

- QR-code linked troubleshooting videos

- Augmented reality maintenance guides

- Performance Optimization Services

- 30-day follow-up inspection

- Annual efficiency audits

- Retrofit and upgrade planning

Conclusion

Proper installation and commissioning are critical for optimal coal packaging system performance. Yuheng Technology delivers:

✔ Heavy-duty packaging solutions engineered for harsh environments

✔ Comprehensive technical support throughout the equipment lifecycle

✔ Cost-competitive manufacturing from China’s leading packaging specialist

Contact our engineering team for a customized installation plan.