Bulk Bag Packaging Machines: Pricing Guide & Professional Commissioning Requirements

Bulk Bag Packaging Machine Price Overview

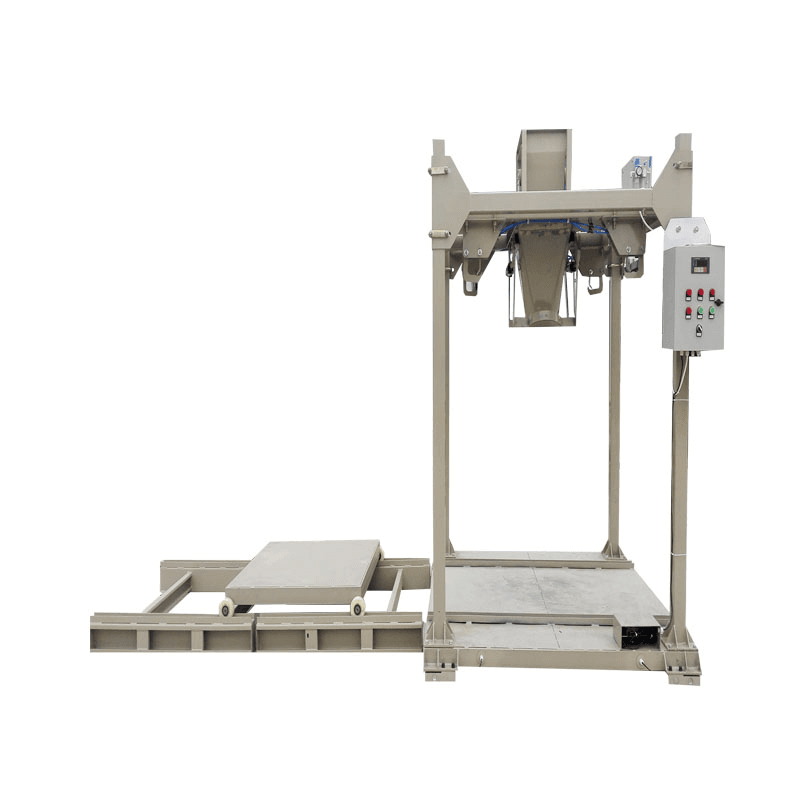

Industrial bulk bag (ton bag) packaging systems are essential for cement, chemicals, minerals, and food processing industries. As a leading Chinese manufacturer with 20 years of FIBC packaging experience, Yuheng Technology produces heavy-duty bulk bag packaging machines that combine precision with durability.

2024 Market Price Range

- Standard Models: $45,000–$90,000

(10-20 bags/hour, 500-1,000kg capacity) - Automated Systems: $90,000–$180,000

(20-40 bags/hour, dust containment) - Custom Solutions: $180,000–$350,000+

(40-80 bags/hour, full robotic integration)

Yuheng Technology Advantages:

✔ Heavy-duty construction for 2,000kg+ bags

✔ IP66 rated electrical components

✔ 4-Year structural warranty

Comprehensive Commissioning Protocol

1. Safety Verification Process

Mandatory Pre-Commissioning Checks:

- Emergency stop circuit functionality test

- Safety light curtain alignment verification

- Mechanical guard interlock testing

- Hazard zone pressure sensors

Operator Certification Requirements:

- 8-hour equipment familiarization

- 4-hour safety system training

- Practical assessment certification

2. Power System Validation

Electrical Specifications:

- Voltage tolerance: ±5% of rated

- Phase balance: <2% variance

- Ground resistance: <4 ohms

Connection Checklist:

✓ Main power cabling (minimum 10mm²)

✓ Control wiring shielding verification

✓ Surge protection installation

3. Mechanical Systems Inspection

Critical Components Check:

- Load Cell System

- Zero balance verification

- Corner load test (≤0.1% variance)

- Shock load protection test

- Material Handling

- Screw conveyor runout <0.5mm

- Bucket elevator chain tension

- Airslide fluidization test

- Bag Handling

- Loop tension adjustment

- Clamp pressure calibration

- Spout centering verification

4. Control System Commissioning

PLC Programming Steps:

- Parameter Initialization

- Bag weight presets

- Fill rate parameters

- Vibration settings

- Sensor Calibration

- Bag presence detectors

- Load cell verification

- Position sensors

- Sequence Testing

- Empty bag loading cycle

- Filling sequence

- Sealing and release

Performance Validation Tests

| Test Type | Standard | Acceptance Criteria |

|---|---|---|

| Single Bag Cycle | 10 repetitions | ±1% time variance |

| Continuous Run | 1 hour | 100% sequence completion |

| Accuracy Test | 20 bags | ±0.5% weight tolerance |

Yuheng’s Commissioning Support Services

1. Professional Startup Packages

- Basic: Remote guidance (2 days)

- Standard: On-site technician (5 days)

- Premium: Engineering team (10 days)

2. Specialized Calibration Equipment

- Certified test weights (M1 class)

- Laser alignment tools

- Vibration analyzers

- Thermal imaging cameras

3. Digital Documentation System

- Interactive 3D manuals

- QR-code linked videos

- Augmented reality guides

Why Global Clients Choose Yuheng

✅ 5,000+ installations in heavy industries

✅ 30% faster commissioning than industry standard

✅ Global spare parts network (48-hour delivery)

✅ Smart monitoring with predictive maintenance

Conclusion

Proper commissioning ensures optimal performance of your bulk bag packaging system. Yuheng Technology offers:

✔ Heavy-duty packaging solutions

✔ Comprehensive startup support

✔ Competitive Chinese manufacturing

Contact our engineers for a commissioning plan today!