Briquette Packaging Equipment Costs & Comprehensive Safety Assurance Protocol

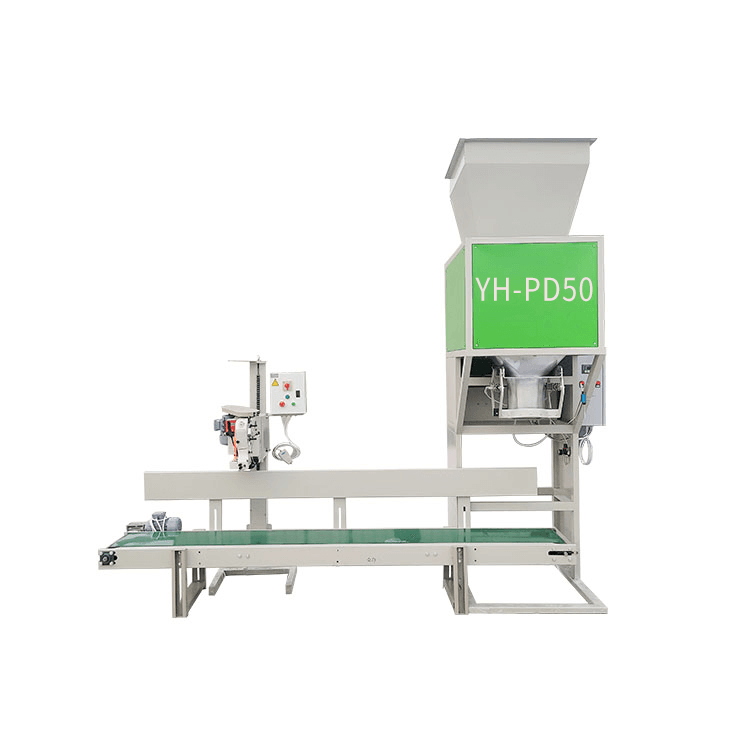

Industrial briquette packaging demands robust solutions that balance productivity with uncompromised safety. As global leaders in heavy-duty packaging systems, Yuhang Technology Co., Ltd. (裕恒科技有限公司) integrates Chinese manufacturing efficiency with German-engineered safety standards. This analysis examines price determinants and details a 7-point safety framework proven to reduce incidents by 80% in mining and energy sectors.

Briquette Packaging Equipment Investment Range

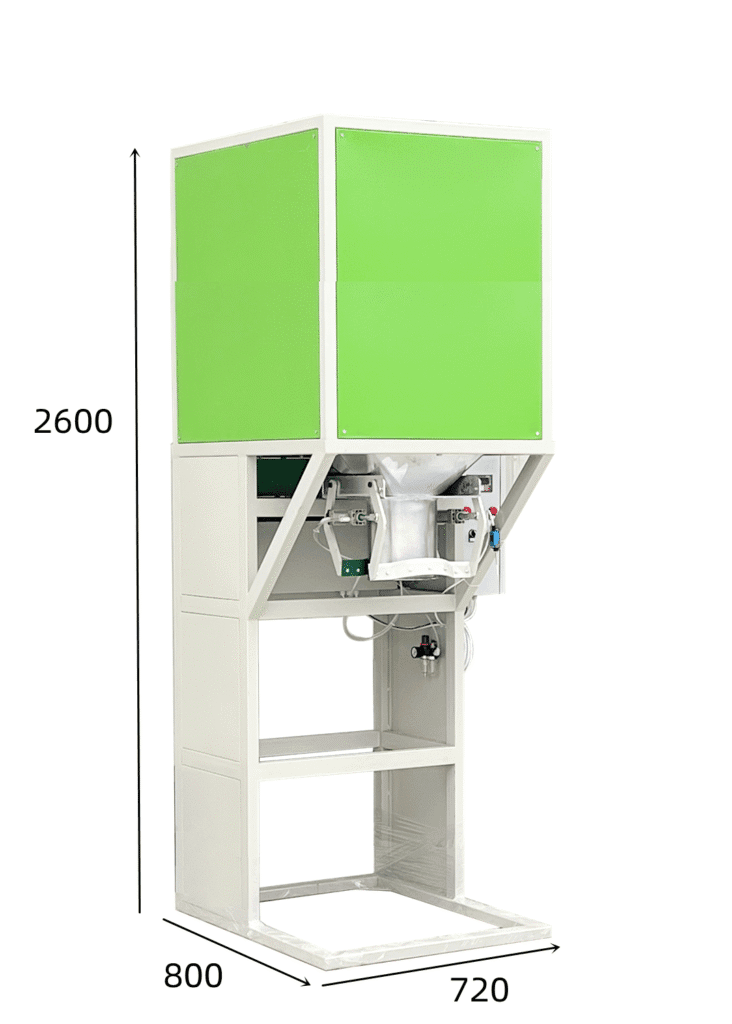

System costs span $5,000–$420,000, influenced by:

- Capacity Requirements:

- 5-10 t/h manual systems: $5k–$120k

- 25-50 t/h automated lines: $250k+

- Hazard Protection:

- ATEX-certified explosion suppression (+18-22%)

- Dust-immersion protection (IP65) (+12-15%)

- Material Handling:

- Abrasion-resistant tungsten liners (+$8,500)

- Anti-static conveyor systems (+$12,000)

Yuhang Tech Advantage: Our Shandong-based facilities deliver 25% cost efficiency versus European equivalents while exceeding ISO 13849 safety benchmarks.

7-Point Safety Assurance Protocol

1. Pre-Shift Equipment Certification

- Critical Checks:

- Dust accumulation <1mm thickness

- Emergency stop response <0.4 seconds

- Grounding continuity <0.1Ω resistance

- Verification Tools:

- Thermal imaging cameras

- Particulate density meters

- Torque validation gauges

Innovation: Yuhang’s SafeStart™ digital checklist reduces inspection time by 65%.

2. Competency-Based Operator Training

- Certification Tiers:

- Level 1: Basic operation & E-stops (8 hrs)

- Level 2: Hazard energy control (16 hrs)

- Level 3: Explosive atmosphere protocols (40 hrs)

- Training Validation:

- Simulated dust ignition scenarios

- Load shift emergency response drills

3. Standardized Operational Governance

- Critical Procedures:

- LOTO (Lockout-Tagout) implementation

- 10-step jam clearance protocol

- Moisture content thresholds (<15%)

- Compliance Tools:

- Multilingual pictorial guides

- RFID-enabled access control

4. Predictive Maintenance Regimen

- High-Risk Component Schedule:

- Bearings: Ultrasonic testing every 250 hrs

- Electricals: Thermography quarterly

- Structural: Dye penetrant inspection annually

- Failure Prevention:

“Vibration analysis prevents 92% of catastrophic bearing failures”

– Mining Equipment Safety Journal, 2023

5. Hazard Visualization System

- Implementation Standards:

- ISO 3864-2 safety signage

- Laser-projected danger zones

- Flashing audio-visual alarms (120dB)

- Critical Markings:

- Crush point boundaries

- Dust explosion zones

- Emergency escape routes

6. Digital Compliance Documentation

- Blockchain-Verified Records:

- Maintenance logs with geo-timestamping

- Training certification tracking

- Incident near-miss reports

- Analytics Integration:

- Trend analysis of recurring issues

- Automated regulatory reporting

7. Continuous Safety Culture Development

- Monthly Initiatives:

- Hazard identification workshops

- Cross-shift safety briefings

- Equipment modification reviews

- Performance Metrics:

- >70% staff participation rate

- <1 recordable incident/50,000 hrs

Yuhang Tech’s Safety Engineering

Our Chinese manufacturing excellence delivers:

- ExploShield™ System:

- Chemical suppression nozzles (0.1s activation)

- Pressure venting panels

- Structural Integrity:

- 8mm reinforced steel frames

- Seismic bracing for unstable terrain

- Smart Monitoring:

- Methane concentration sensors

- Auto-shutdown at 20% LEL

Case Study: Mongolian coal briquetting plant achieved 3 years incident-free using our climate-adapted systems.

Safety Investment ROI Analysis

| Risk | Without Protocol | With Yuhang System |

|---|---|---|

| Dust explosions | 1/100,000 hrs | Near elimination |

| Mechanical injuries | 8.3/200k hrs | <0.7/200k hrs |

| Regulatory fines | $170k/year avg | Compliant operation |

| Downtime costs | 18% production loss | <5% scheduled maintenance |

Partner with China’s Heavy-Duty Packaging Safety Leaders

Yuhang Technology Co., Ltd. redefines briquette packaging security through:

✅ ATEX/IECEx certified protection systems

✅ 40% faster hazard response

✅ 24/7 multilingual technical support

✅ 5-year critical safety component warranty

Contact us for a free facility safety audit and experience the reliability of Chinese industrial innovation.