Granular Packaging System Costs & 6 Essential Design Standards

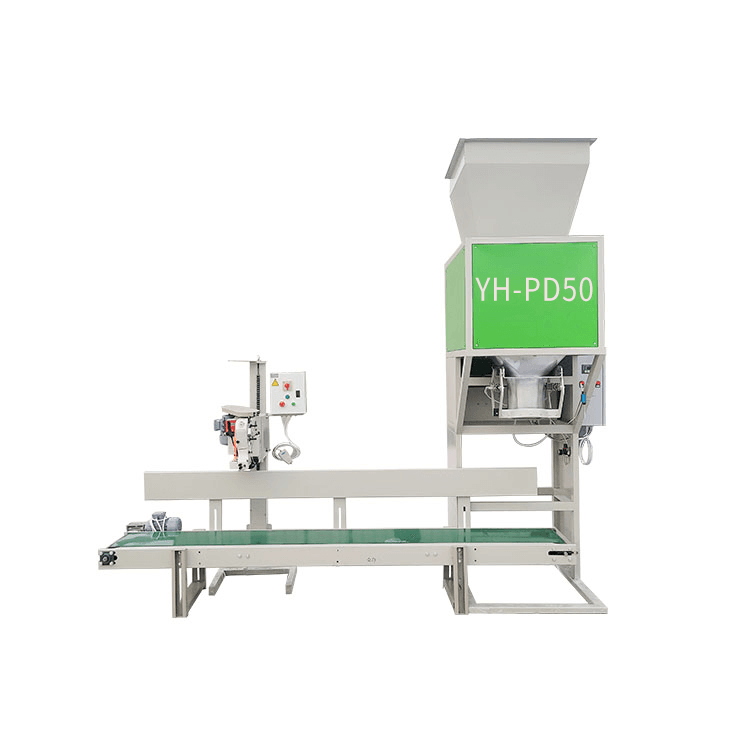

Granular packaging systems represent significant investments for producers of seeds, pharmaceuticals, and food products. As a leader in industrial automation, Yuhang Technology Co., Ltd. combines Chinese manufacturing efficiency with global engineering standards. This analysis examines pricing variables and details the critical design principles ensuring operational excellence.

Granular Packaging System Investment Range

Turnkey solutions span $4,000–$800,000, influenced by:

- Throughput Requirements

- 20-50 bags/min: $4k–$120k

- 200+ bags/min: $300k+

- Material Handling Complexity

- Free-flowing grains vs. cohesive powders (+18-25%)

- Automation Level

- Robotic palletizing integration (+$35k–$80k)

Yuhang Tech Advantage: Our Shenzhen-based production delivers 25-30% cost efficiency versus European counterparts while maintaining ISO 9001 certification.

6 Critical Design Standards for Optimal Performance

1. Production Efficiency Optimization

- Key Metrics:

- >95% OEE (Overall Equipment Effectiveness)

- <3% changeover downtime

- Yuhang Implementation:

- AI-driven predictive scheduling

- Quick-change tooling (under 15 minutes)

2. Packaging Integrity Assurance

- Quality Benchmarks:

ParameterFood GradePharmaceutical

Seal Strength ≥35N/15mm ≥50N/15mm

Moisture Barrier ≤0.5g/m²/24hr ≤0.1g/m²/24hr

Contamination <50 particles/m³ ISO Class 8 3. Sustainable Material Utilization- Cost Control Strategies:Precision filling (±0.5% variance)Recyclable material compatibilityFilm thickness optimization algorithmsCase Study: Vietnamese coffee exporter reduced packaging costs 22% using our material-saving systems

- Design Features:Tool-free access panelsCentralized lubrication pointsColor-coded pneumatic linesYuhang Innovation:QR-coded components linking to 3D repair guides

- Layout Principles:U-shaped configurations minimizing movementVertical material transfer systems<5 meter inter-station distancesEfficiency Impact:30% reduction in floor space requirements40% faster line balancing

- Compliance Requirements:Noise emissions <75 dB(A)Dust explosion prevention (ATEX Zone 22)Energy recovery systemsYuhang Solutions:Solar-compatible drive systemsClosed-loop water filtration

- Rapid Deployment: 60-day custom solution developmentClimate Adaptation: Tropicalized systems for SEA marketsSmart Scalability: Modular expansion capabilitiesGlobal Compliance: CE, UL, GOST-R pre-certification

Yuhang Technology Co., Ltd. redefines packaging system design through:

✅ 30% faster project commissioning

✅ 24/7 multilingual engineering support

✅ 5-year critical component warranty

✅ Carbon-neutral manufacturing options Contact us for a free line efficiency assessment and experience Chinese engineering excellence.