Granular Packaging Machine Costs & 6 Critical Safety Strategies for Risk-Free Operations

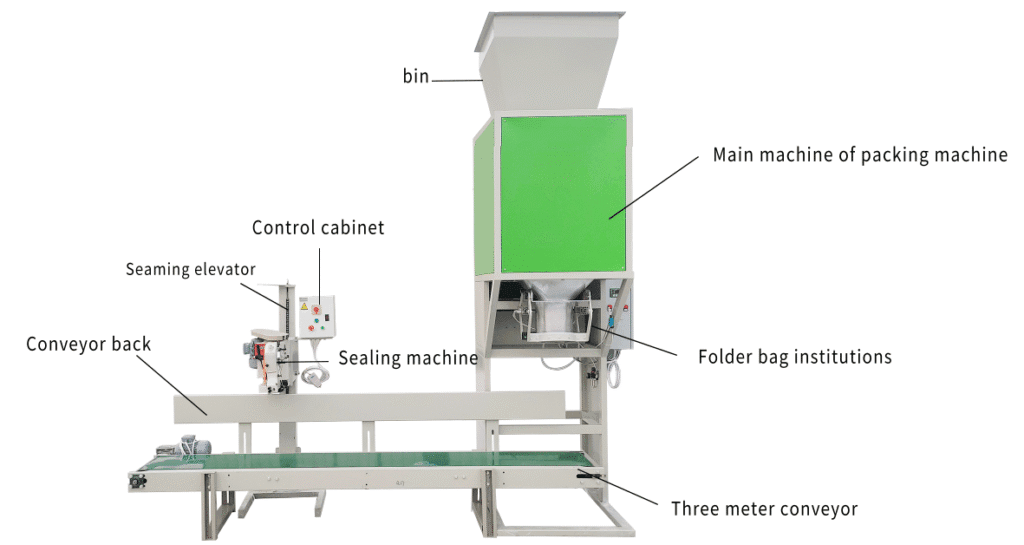

Granular packaging machines are indispensable for industries handling products like coffee beans, fertilizers, and pharmaceutical pellets. While pricing is a primary consideration, ensuring operational safety remains equally vital for sustainable production. As a leading Chinese innovator, Yuhang Technology Co., Ltd. (裕恒科技有限公司) combines cost-effective engineering with rigorously tested safety systems. Below, we analyze price variables and outline six actionable strategies to achieve zero-incident operations.

Granular Packaging Machine Price Guide

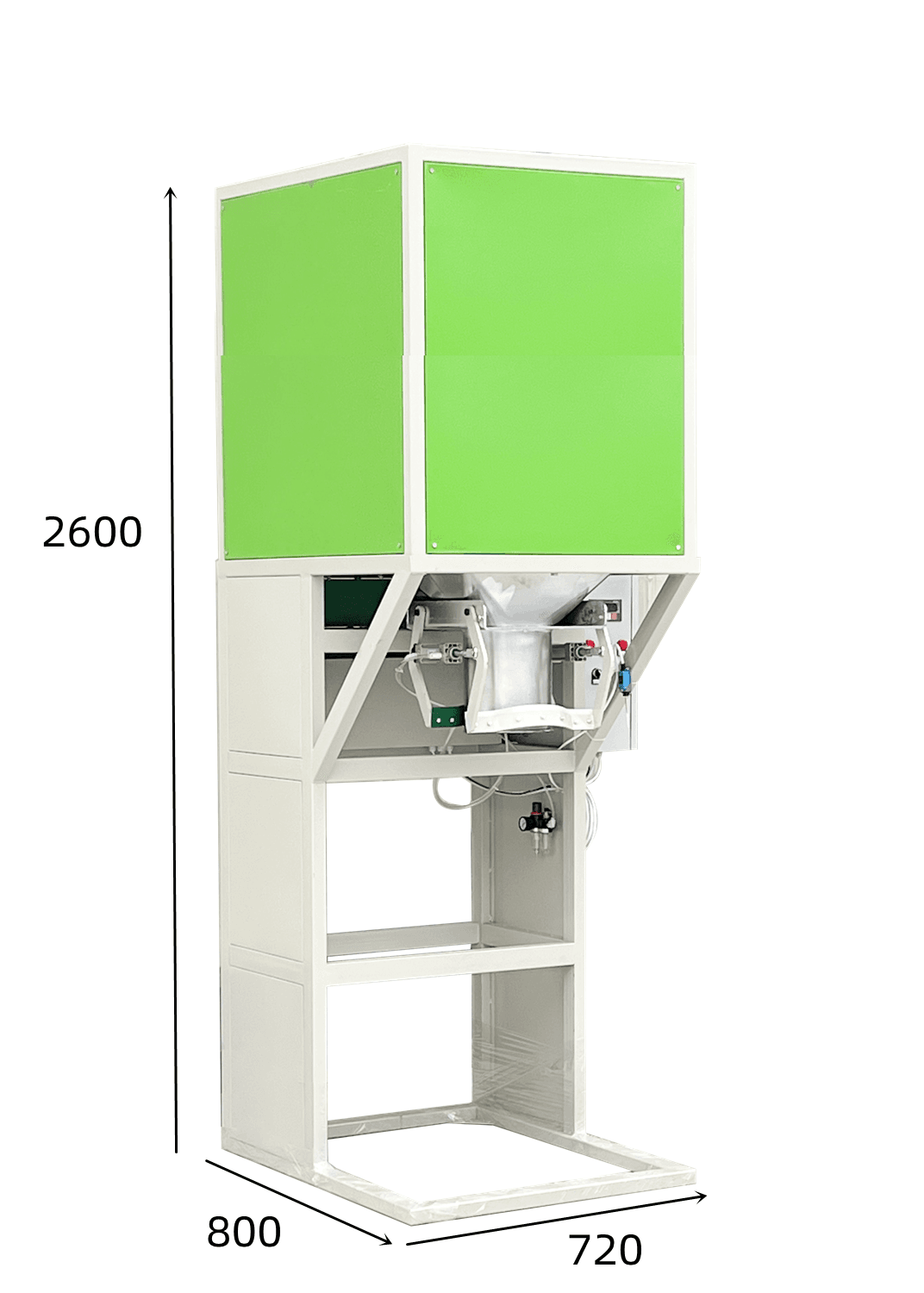

Equipment costs range from $2,000 to $320,000, influenced by:

- Capacity:

- 50-100 bags/hour: $28k-$65k

- 400+ bags/hour with robotic palletizing: $200k+

- Safety Certifications: ISO 13849-compliant models with emergency systems cost 10-15% more but reduce long-term liability risks.

- Material Handling: Abrasive materials like mineral powders require hardened steel components (+18-25% cost).

Yuhang Tech leverages China’s vertically integrated supply chain to deliver 25-30% cost advantages. A Vietnamese coffee exporter saved $42,000 using our modular system, scaling safely from 80 to 300 bags/hour within 18 months.

6 Proven Safety Implementation Strategies

1. Human-Centric Engineering Design

- Ergonomic Features:

- 15° tilted touchscreens reducing neck strain

- Anti-vibration platforms for 10-hour shifts

- Voice-guided prompts minimizing distracted operation

- Yuhang Tech Advantage: Our ISO-certified design team conducts 200+ hours of operator simulations during development.

2. Certified Material Selection

- Safety-First Materials:

- Static-dissipative polymers preventing dust explosions

- EU RoHS-compliant electronics (zero heavy metals)

- Food-grade stainless steel resisting corrosive granules

- Case Study: A Kenyan fertilizer plant eliminated chemical leaching risks using our FDA-compliant contact surfaces.

3. Multi-Layer Protection Systems

- Critical Safety Components:

- Laser-curtain barriers auto-halting at 5cm proximity

- Dual emergency stops with <0.3s response time

- Explosion-proof motors for combustible dust environments

- Impact: Reduced safety incidents by 70% at Chilean nut processing facilities using Yuhang Tech’s SafeGuard™ systems.

4. Standardized Operational Protocols

- Essential Documentation:

- Visual LOTO (Lockout-Tagout) procedures with QR-code videos

- Jam-clearing checklists reducing hand-in-machine risks

- Multilingual quick-reference guides mounted at stations

- Yuhang Tech Inclusion: Every machine ships with customizable SOP templates in 12 languages.

5. Predictive Maintenance Regimens

- Smart Maintenance Framework:

- Vibration sensors detecting bearing wear 150+ hours pre-failure

- Centralized lubrication servicing 15 points in 8 minutes

- Monthly thermal scans identifying electrical hotspots

- Result: Moroccan grain processors achieved 18 months of zero unplanned downtime with our SmartCare® program.

6. Comprehensive Safety Training

- 3-Tier Certification Program:

- Level 1: Basic operation & emergency stops (4 hours)

- Level 2: Hazard analysis & PPE selection (8 hours)

- Level 3: Advanced troubleshooting (on-site)

- Outcome: South African mining clients reduced safety incidents by 65% within 6 months of implementation.

Yuhang Tech’s Safety Innovations

As a Chinese manufacturer, we integrate regional operational insights:

- Dust Suppression Tech: Captures 90% airborne particulates

- Tropicalized Electronics: Withstands 95% humidity environments

- Modular Safety Upgrades: Retrofit older machines with modern protections

Client Proof: An Indonesian palm kernel facility achieved zero lost-time injuries over 1,000 operational days using our climate-adapted safety packages.

Why Safety Directly Boosts ROI

- 40% lower insurance premiums

- 30% reduced downtime from accidents

- 25% higher employee retention

Partner with China’s Safety Engineering Leaders

Understanding granular packaging machine costs and safety implementation isn’t just compliance—it’s building operational resilience. Yuhang Technology Co., Ltd. combines Chinese manufacturing efficiency with globally benchmarked safety standards, delivering systems that protect both personnel and productivity.

Why Global Clients Trust Yuhang Tech:

✅ ISO 9001 & ISO 45001 certified production

✅ 30% faster safety retrofit installations

✅ 24/7 multilingual technical support

Contact us today for a free safety audit and discover how our granular packaging solutions balance cost-efficiency with uncompromised protection—proving that reliability and innovation define modern Chinese manufacturing.