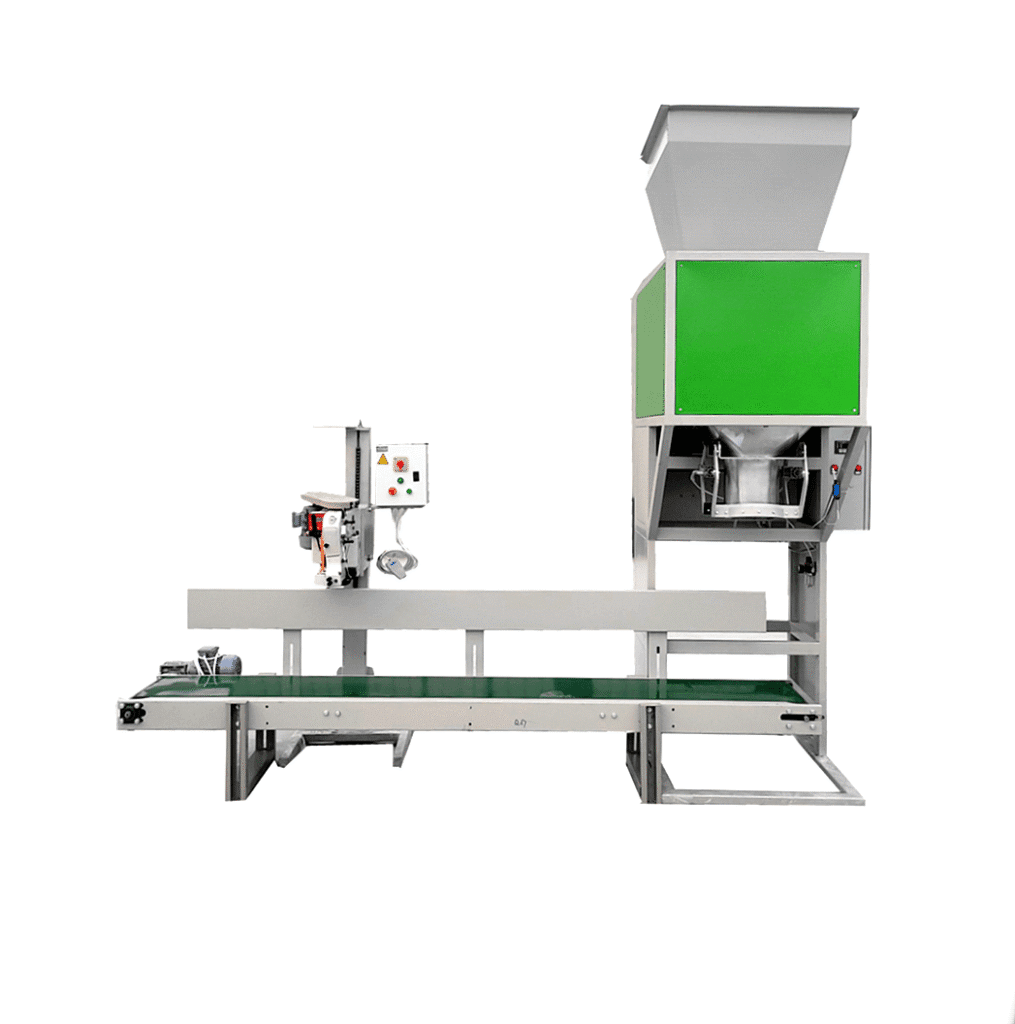

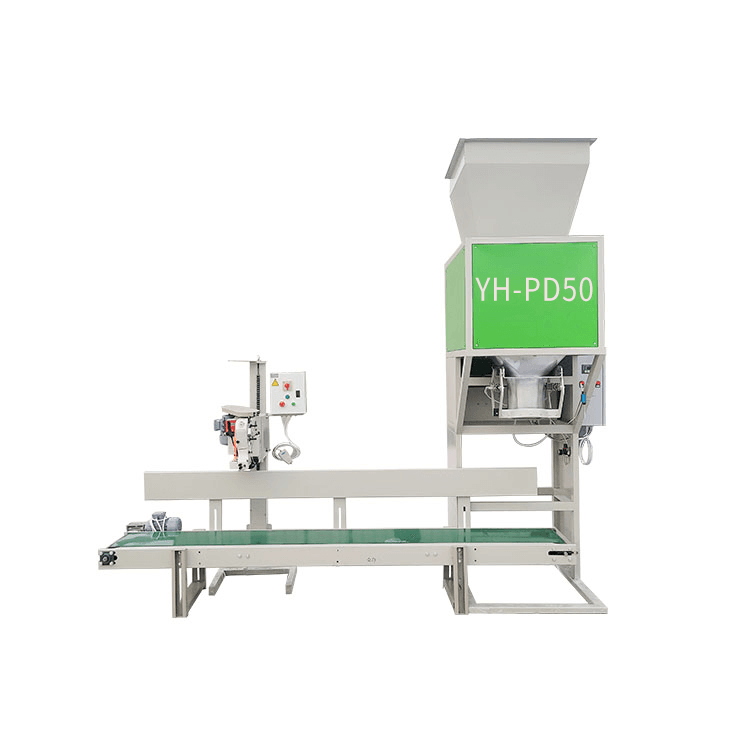

Organic Fertilizer Packaging Equipment Costs & Professional Maintenance Guidelines

Organic fertilizer packaging equipment plays a vital role in sustainable agriculture, ensuring precise weighing and sealing for eco-friendly fertilizers. For businesses balancing cost and reliability, two questions arise: What factors determine organic fertilizer packaging machine prices? and How to address breakdowns safely and efficiently? Yuhang Technology Co., Ltd. (裕恒科技有限公司), a leading Chinese manufacturer, combines affordable engineering with robust maintenance protocols to maximize equipment uptime. Below, we analyze pricing variables and outline a step-by-step repair framework trusted by global clients.

Organic Fertilizer Packaging Equipment Price Factors

Costs range from $8,000 to $180,000, influenced by:

- Capacity: Machines packing 10–20 tons/day start at $28k, while 50+ ton systems exceed $150k.

- Dust Resistance: Corrosion-proof coatings and sealed bearings add 15–25% to pricing but extend lifespan in abrasive environments.

- Automation Level: Semi-automatic models suit small farms, while AI-driven lines with palletizing robots cater to industrial-scale operations.

Yuhang Tech leverages China’s manufacturing ecosystem to deliver 20–30% cost savings. A Kenyan organic farm reduced upfront investment by 35% using our modular system, scaling from 5 to 25 tons/month as demand grew.

6-Step Professional Repair Protocol

1. Power Shutdown & Safety Lockout

- Critical Actions:

- Activate emergency stop button.

- Use lockout-tagout (LOTO) devices to prevent accidental restarts.

- Discharge residual energy from pneumatic/hydraulic systems.

Yuhang Tech’s machines feature dual-circuit power cutoff and color-coded LOTO points, praised by Brazilian clients for accident prevention.

2. Systematic Fault Diagnosis

- Tools & Methods:

- Infrared thermometers to detect overheating bearings.

- Vibration analyzers for misaligned auger drives.

- Error code interpretation via touchscreen logs.

In a Vietnamese case, our SmartDiagnose system pinpointed a faulty load cell in 8 minutes, reducing troubleshooting time by 70%.

3. OEM-Approved Repair Procedures

- Compliance:

- Follow Yuhang Tech’s multilingual repair manuals (provided with QR-code access).

- Use torque wrenches for bolt adjustments (±5% tolerance).

- Replace wear parts (e.g., sealing jaws) in matched pairs.

A Moroccan client avoided secondary damage by replacing both conveyor chain sprockets simultaneously, per our guidelines.

4. Genuine Part Replacement

- Yuhang Tech’s Standards:

- Laser-etched component IDs for authenticity verification.

- Pre-greased bearings for immediate installation.

- Material compatibility checks (e.g., stainless steel vs. organic acids).

Our Global Spare Network guarantees 48-hour delivery for 90% of components, as demonstrated during a Nigerian client’s critical harvest-season repair.

5. Post-Repair Deep Cleaning

- Protocol:

- Vacuum fertilizer dust from electrical cabinets.

- Steam-clean hoppers with food-grade detergents.

- Apply anti-corrosion spray to exposed metal surfaces.

Yuhang Tech’s QuickClean ports allow rapid debris removal, cutting cleaning time by 50% in Indonesian palm waste facilities.

6. Performance Validation Testing

- Checklist:

- 30-minute no-load run to verify smooth operation.

- Weighing accuracy test (±0.5% tolerance).

- Dust leakage check at 150 Pa pressure.

Following repairs, a Chilean client achieved 99.3% packaging accuracy across 500 test bags using our calibration protocols.

Yuhang Tech’s Maintenance Innovations

As a Chinese manufacturer, we design for simplified upkeep:

- Centralized Lubrication: Service 12+ bearing points through one port.

- Modular Design: Swap damaged augers or hoppers in <15 minutes.

- Corrosion Defense: Nano-coated electronics withstand ammonia-rich fertilizer vapors.

Case Study: A Thai organic cooperative extended machine life by 5 years using our humidity-resistant models, despite coastal salt air exposure.

Why Proper Repairs Impact ROI

Neglecting protocols risks:

- 50% higher long-term repair costs

- 30% productivity loss from repeat failures

Yuhang Tech mitigates this through:

- 3-Year Extended Warranties: Covering labor and parts for critical systems.

- Remote Guidance: AR-assisted repairs via 24/7 video support.

Partner with China’s Organic Packaging Experts

Understanding organic fertilizer packaging equipment costs and maintenance isn’t just about budgets—it’s about sustainable productivity. Yuhang Technology Co., Ltd. combines Chinese manufacturing efficiency with globally compliant engineering, delivering systems built for harsh agricultural environments. From family farms to industrial composters, our clients achieve 40% fewer breakdowns through intelligent design and disciplined care.

Contact Yuhang Tech today to explore durable, cost-effective packaging solutions that keep your organic operations running smoothly, season after season.