Packaging Equipment Costs & Future Industry Trends: Key Insights for Businesses

As global industries evolve, packaging equipment has become a cornerstone of efficient production lines, balancing cost-effectiveness with innovation. For businesses navigating this dynamic landscape, two critical questions arise: What factors influence packaging equipment pricing? and What future trends will redefine the industry? Yuhang Technology Co., Ltd. (裕恒科技有限公司), a leading Chinese innovator, addresses these questions by merging China’s manufacturing expertise with cutting-edge engineering. Below, we analyze pricing variables and forecast five transformative trends shaping tomorrow’s packaging solutions.

Packaging Equipment Price Ranges

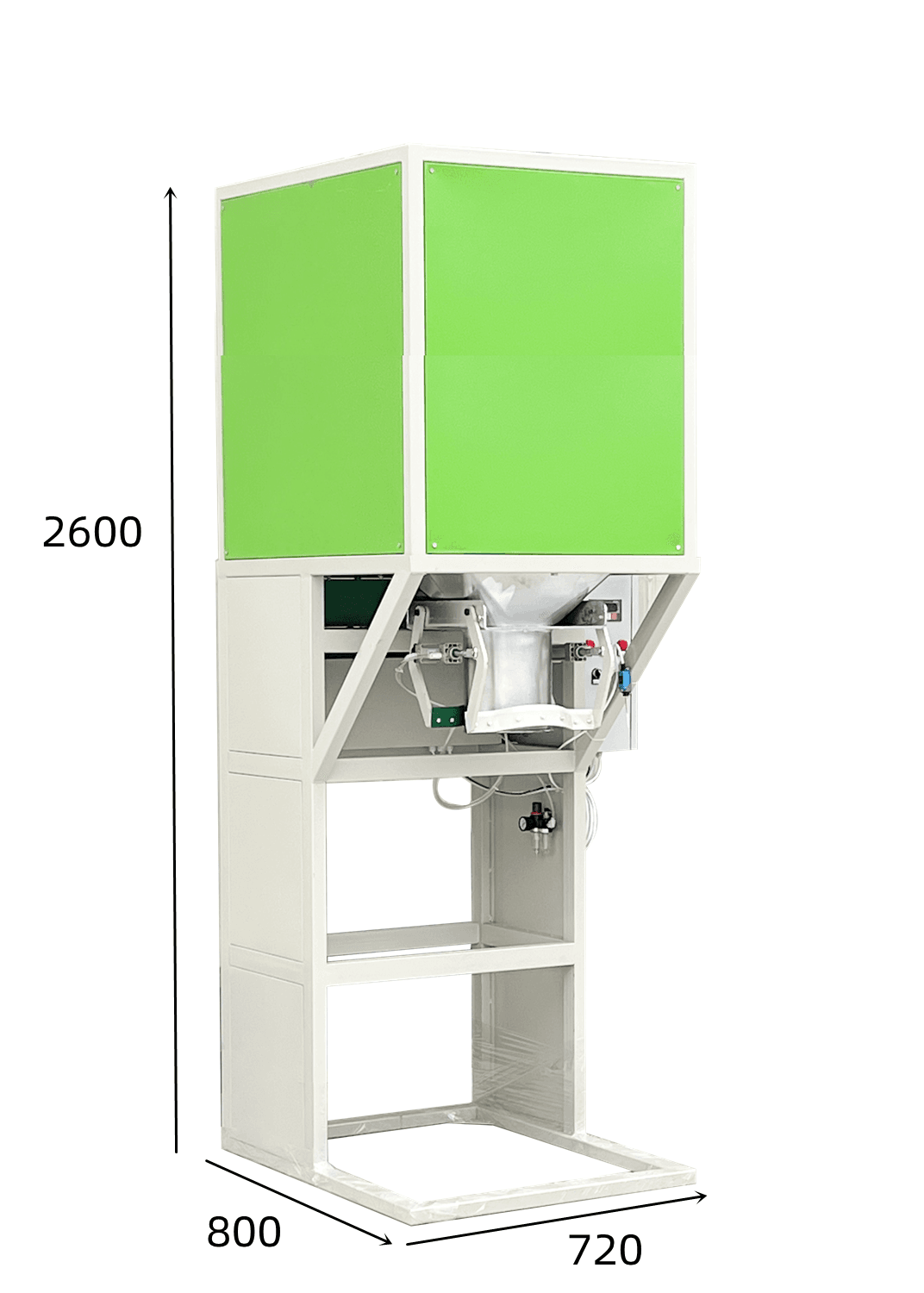

Costs vary widely based on functionality, ranging from $25,000 for basic semi-automatic systems to $1.2 million+ for fully automated smart lines. Key price drivers include:

- Automation Level: AI-driven systems with real-time analytics command premium pricing.

- Material Compatibility: Machines handling abrasive or sterile materials require specialized coatings.

- Production Speed: High-capacity systems (150+ units/minute) cater to large-scale operations.

Yuhang Tech leverages China’s vertically integrated supply chain to deliver 20–30% cost advantages, as seen in a recent project with a Thai rice exporter who saved $78,000 using our modular packaging line.

5 Future Directions Redefining Packaging Equipment

1. Autonomous Intelligence

Tomorrow’s machines will transcend basic automation through:

- Self-Learning Algorithms: Adjusting sealing temperatures based on material humidity.

- Predictive Maintenance: IoT sensors forecasting part failures 72+ hours in advance.

Yuhang Tech’s SmartPack Pro series, deployed in a Vietnamese coffee facility, reduced human intervention by 70% while boosting output accuracy to 99.8%.

2. Hyper-Connected Production Ecosystems

Integration will dominate through:

- Plug-and-Play Modules: Switching from bottles to pouches in 10 minutes.

- Cloud-Based Coordination: Synchronizing packaging lines with ERP systems for real-time inventory updates.

A Chilean winery streamlined operations using our integrated system, cutting order fulfillment time by 40% through seamless equipment-software synergy.

3. Green Engineering as Standard

Sustainability will transition from niche to norm via:

- Biodegradable Material Compatibility: Machines adapting to plant-based films and recycled plastics.

- Energy Recovery Systems: Recapturing 85% of braking energy from conveyor belts.

Yuhang Tech’s EcoFlex line, featuring solar-powered components, helped a Nigerian agro-processor reduce carbon emissions by 35% annually.

4. Advanced Material Innovation

Emerging materials will drive equipment redesigns:

- Nanotech Coatings: Anti-microbial surfaces for pharmaceutical packaging.

- Edible Films: Machines handling delicate, water-soluble wrappers for eco-friendly snacks.

Our collaboration with a Shanghai biotech firm produced packaging systems for seaweed-based films, now used by Japanese confectionery brands.

5. Mass Customization Capabilities

Demand for personalized packaging will spur:

- Laser-Guided Design Systems: Printing unique QR codes or artwork on-the-fly.

- AI-Powered Format Switching: Automatically adjusting settings for limited-edition runs.

A Brazilian cosmetics client leveraged Yuhang Tech’s CustomMaster line to produce 50+ personalized SKUs monthly, increasing market share by 18%.

Yuhang Tech: Bridging Chinese Efficiency with Global Innovation

As a Chinese manufacturer, we turn regional strengths into client advantages:

- Rapid Prototyping: Develop custom solutions in 45 days (vs. 90+ for Western competitors).

- Cost Stability: Localized raw ma

tainability regulations.

- 20% Higher Margins: Reducing material waste and energy costs.

- 50% Fewer Downtimes: Predictive systems preventing unplanned halts.

Partner with China’s Packaging Pioneers

The packaging industry’s future lies in agility, sustainability, and intelligence. Yuhang Technology Co., Ltd. embodies these principles through Chinese engineering excellence, delivering equipment that adapts to tomorrow’s challenges today. From AI-driven automation to zero-waste production lines, our solutions empower businesses to lead in competitive markets.

Contact Yuhang Tech to explore how our packaging systems can future-proof your operations while maximizing ROI—proving that innovation and affordability coexist in China’s manufacturing landscape.