Fertilizer Packaging Machine Costs & Strategic Expansion for Industry Growth

Fertilizer packaging automation is revolutionizing agricultural supply chains, offering efficiency gains for producers and distributors alike. Below, we analyze equipment pricing and outline actionable strategies for manufacturers to expand market reach while maintaining competitive advantage.

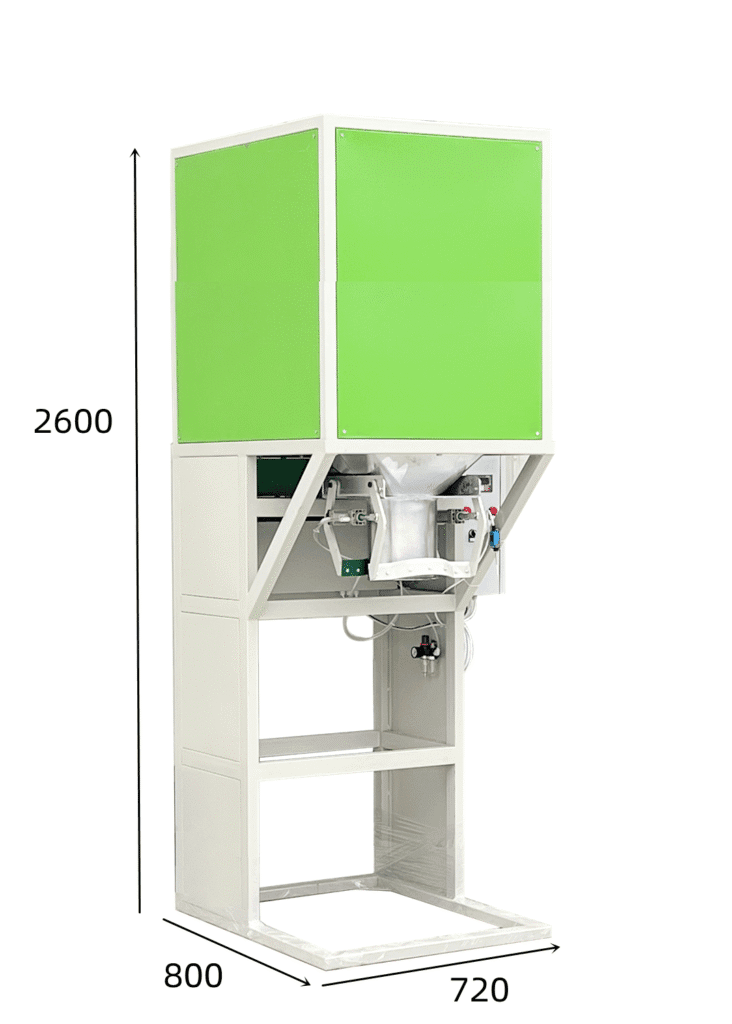

Fertilizer Automatic Packaging Machine Pricing

Investment costs vary by capacity and features:

- Entry-level semi-automatic: $35,000–$65,000 (15–30 bags/hour)

- Mid-range automated: $70,000–$140,000 (40–80 bags/hour)

- High-volume systems: $150,000+ (IoT-enabled, 100+ bags/hour)

Chinese manufacturers like YU-HENG Technology deliver 30–45% cost savings compared to European brands, with ISO 9001-certified quality and 4–6 week lead times.

6 Strategies to Expand Market Penetration

1. Product Innovation for Diverse Needs

- Smart weighing: AI-powered load cells achieve ±0.5% accuracy for variable-density fertilizers.

- Modular designs: Switch between granular urea (0.08–0.2″/2–5 mm) and powdered NPK blends in <10 minutes.

- Sustainability focus: Energy recovery systems reduce power consumption by 20–25%.

Case Study: A Brazilian agribusiness increased market share by 18% after adopting customizable packaging systems.

2. Global Market Expansion

- Target regions:

- Southeast Asia: Growing demand for blended fertilizers.

- Africa: Government subsidies boosting mechanization.

- Tactics:

- Exhibit at trade shows (e.g., AGRITECHNICA).

- Partner with local distributors for logistics support.

3. Service Excellence as a Differentiator

- 360° support:

Service Key Metrics

On-site installation <72-hour global response

Operator training Multilingual VR simulations

Spare parts delivery 48-hour availability in 50+ countries 4. Omnichannel Sales Networks- Digital platforms:Real-time remote machine demos via AR.E-commerce portals for consumables (bags, sensors).Distributor incentives:Volume-based discounts (5–15%).Co-branded marketing campaigns.

- Content marketing:Publish whitepapers on sustainable packaging trends.Webinars showcasing IoT-driven yield optimization.Certifications: Highlight compliance with ISO 14001 (environmental management) and OHSAS 18001 (safety).

- Priority areas:Dust suppression for ammonium nitrate packaging.Blockchain-enabled traceability for organic fertilizers.Solar-powered mobile units for rural markets.

- Phase 1 (0–6 months): Pilot IoT-enabled machines in 2–3 strategic markets.Phase 2 (6–18 months): Establish regional warehouses and training centers.Phase 3 (18–36 months): Launch solar/hybrid models for off-grid regions.

- Speed: Adapt designs from prototype to production in 4 weeks.Cost: Localized component sourcing cuts prices 25–30%.Flexibility: Customize bag sizes from 5–100 lb (2.3–45 kg).