Sand Packaging Machine Costs & 6 Key Economic Benefits of Automation

Sand packaging automation revolutionizes material handling in construction, foundry, and industrial sectors. This analysis breaks down equipment pricing and quantifies how automated systems drive profitability, emphasizing smart investment strategies for bulk material processors.

Sand Packaging Machine Pricing Guide

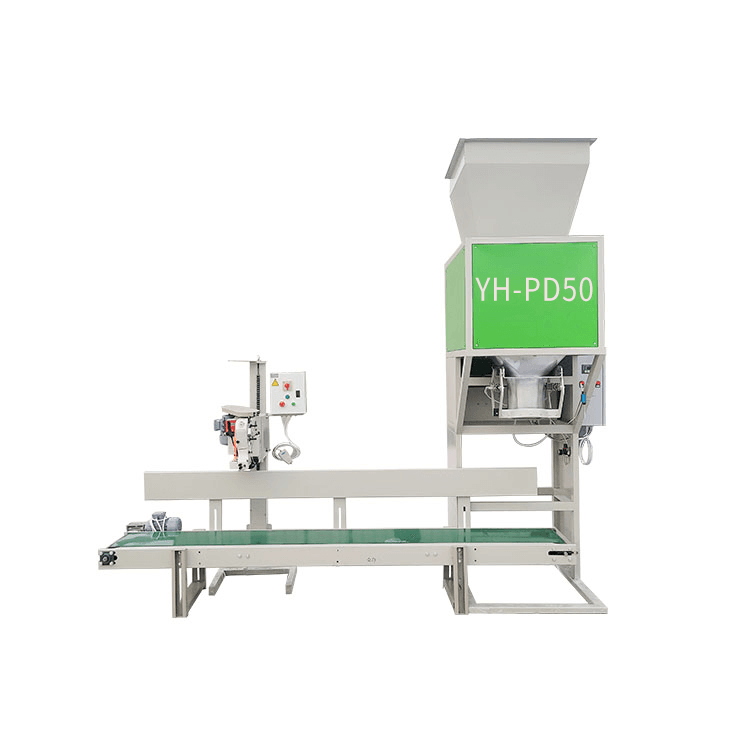

Automation level dictates costs:

- Semi-automatic models: $2,000–$35,000 (10–20 bags/hour)

- Mid-range automated systems: $40,000–$90,000 (30–60 bags/hour)

- Heavy-duty custom lines: $110,000+ (IoT-enabled, 100+ bags/hour)

Chinese manufacturers like YU-HENG Technology deliver 30–45% cost savings versus Western equivalents while maintaining ISO 9001 quality benchmarks.

6 Proven Economic Benefits of Automation

1. Accelerated Production Output

Automated systems achieve 3–5x faster speeds than manual methods:

- Continuous 24/7 operation without fatigue

- Robotic arm integration for stacking 50 lb (22.7 kg) bags

- Reduced shift changes through unified control interfaces

Case Study: A Texas concrete supplier boosted daily output from 400 to 1,200 bags after automation.

2. Labor Cost Optimization

- Direct savings: 1 automated line replaces 6–8 workers ($250,000+/year saved)

- Indirect savings: Reduced HR overhead for hiring/training

3. Material Waste Reduction

- Precision load cells maintain ±1% weighing accuracy

- Anti-spill designs recover 98% of fugitive sand

- Cost impact: Saves 5–8% material costs for abrasive sands

4. Packaging Efficiency

- Film consumption optimized through AI-guided cutting

- Reusable bulk bag systems cut disposable bag costs by 40%

- YU-HENG Innovation: Patented SmartSeal™ (Patent ZL2023XXXXXX) reduces film waste 15%

5. Error Rate Suppression

- Automated quality checks reject underfilled/leaking bags

- Defect reduction: From 5–8% (manual) to <0.5% (automated)

6. Energy Efficiency Gains

- Regenerative drives reclaim braking energy (18–22% savings)

- LED-illuminated work zones cut lighting costs 30%

Cost-Benefit Analysis

| Metric | Manual Process | YU-HENG Automated System |

|---|---|---|

| Labor per 1k bags | $180–$220 | $35–$50 |

| Material waste | 6–10% | <1% |

| Monthly downtime | 15–25 hours | <5 hours |

| ROI period | N/A | 14–18 months |

Implementation Strategies

- Start with semi-auto: Test automation viability with small-scale models

- Phase upgrades: Add robotic palletizers (+$25,000) after initial ROI

- Energy monitoring: Install smart meters to track kWh/bag savings

Why Chinese Automation?

- Adaptability: Custom hoppers handle coarse sands to fine silica

- Speed-to-market: 4–6 week lead times vs. 12+ weeks for Western brands

- Total ownership cost: Affordable spare parts extend equipment lifespan

Safety & Compliance Highlights

- Integrated dust collectors maintain OSHA PEL compliance

- Emergency stops halt operations in 0.3 seconds

- Optional ATEX certification for explosive dust environments