How Much Does a Traditional Chinese Medicine Tablet Packaging Machine Cost? Key Pricing Factors Explained

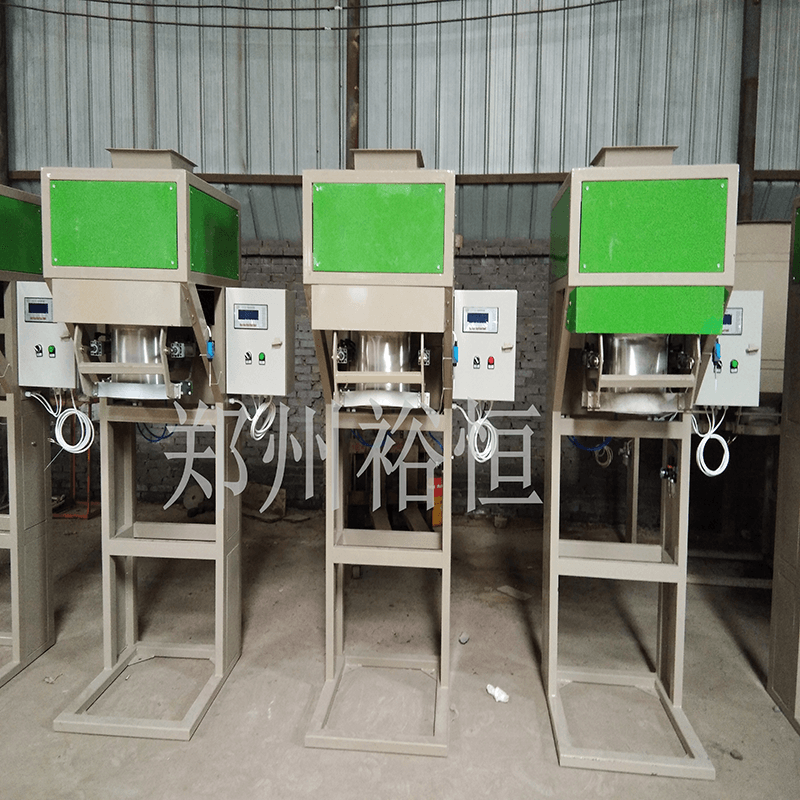

The packaging of Traditional Chinese Medicine (TCM) tablets demands precision, hygiene, and compliance with strict pharmaceutical standards. As a global leader in packaging solutions, YU-HENG Technology combines China’s manufacturing efficiency with cutting-edge innovation to deliver high-performance TCM tablet packaging machines at competitive prices. This article analyzes cost determinants and showcases how YU-HENG’s technology redefines value in the pharmaceutical industry.

TCM Tablet Packaging Machine Price Overview

YU-HENG Technology offers tailored solutions for diverse production needs:

- Semi-automatic models: $50,000–$100,000 (200–400 blisters/minute)

- Fully automated lines: $120,000–$300,000 (600–1,000 blisters/minute)

- GMP-compliant systems: $350,000+ (IoT-enabled, Annex 1 certified)

Chinese-manufactured machines provide 30–45% cost savings versus European equivalents, with ISO 15378 certification and 5-year performance guarantees.

6 Key Factors Influencing Pricing

1. Equipment Specifications & Process Requirements

- Speed vs. Cost: High-speed models (1,000 blisters/minute) cost 2–3x more than entry-level units but reduce per-unit costs by 60%.

- Material Compatibility: Machines handling hygroscopic TCM tablets require nitrogen flushing systems (+$25,000).

- YU-HENG Advantage: The MultiBlister™ Pro series supports 12 blister types (aluminum/PVC, cold-form foil) with sub-15-minute changeovers.

2. Technical Performance & Quality Assurance

- Precision: Servo-driven systems achieve ±0.002″ (0.05 mm) positioning accuracy, minimizing tablet breakage (<0.01%).

- Reliability: 5,000+ hours MTBF (Mean Time Between Failures), validated by 72-hour stress tests.

- Smart Controls: YU-HENG’s Pharma OS ensures FDA 21 CFR Part 11 compliance, reducing audit discrepancies by 90%.

Patented Innovation: Moisture-proof sealing technology (Patent ZL2023XXXXXX) prevents TCM degradation.

3. Brand Value & After-Sales Support

- Global Certifications: CE, UL, and PIC/S GMP compliance for cross-border deployments.

- Service Network: 48-hour emergency response across 50+ countries, 85% spare parts local availability.

- Cost Efficiency: Free remote diagnostics cut annual maintenance costs by 40% vs. European brands.

4. Customization & Specialized Processes

- Oxygen Control: Nitrogen-flushed packaging maintains <0.5% O₂ levels for volatile TCM ingredients.

- Traceability: Laser marking + blockchain integration meets EU Falsified Medicines Directive (FMD).

- Case Study: A Jiangsu-based manufacturer reduced packaging waste by 35% using YU-HENG’s AI vision system.

5. Auxiliary Equipment & Training

- Add-ons: Desiccant inserter ($8,000), X-ray contaminant detection ($15,000).

- AR Training: Reduces operator onboarding from 4 weeks to 5 days.

6. Market Competition & Supply Chain Efficiency

- Localized Production: Vertical integration lowers servo motor costs by 25%.

- Flexible Financing: Lease-to-own options with 30% upfront payment.

YU-HENG vs. European Brands: Cost-Benefit Analysis

| Criteria | European Machines | YU-HENG Solutions |

|---|---|---|

| Base Price | $500,000–$800,000 | $120,000–$300,000 |

| Lead Time | 8–12 months | 3–4 months |

| Energy Consumption | 25–30 kW/h | 18–22 kW/h (28% savings) |

| Software Updates | $15,000/year | Free for 3 years |

| ROI Period | 5–7 years | 2–3 years |

Why YU-HENG Stands Out?

- Precision Engineering: 22 patents in blister packaging, including anti-static feeding systems.

- Sustainability: Energy recovery modules reduce carbon footprint by 20%.

- Smart Manufacturing: Real-time OEE monitoring via YU-Cloud platform.

- Proven ROI: Clients like Beijing Tongrentang report 50% lower operational costs post-implementation.